US 211743

UNITED STATES PATENT OFFICE.

BENJAMIN F. JOSLYN, OF WORCESTER, MASSACHUSETTS.

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 211,743, dated January 28, 1879; application filed October 2, 1878.

To all whom it may concern:

Be it known that I, Benjamin F. Joslyn, of Worcester, in the State of Massachusetts, have invented a new and useful Improvement in Revolving Fire-Arms; and that the following is a full, clear, and exact description there of, reference being had to the accompanying drawings, making a part of this specification, and to the letters of reference marked thereon.

My invention has for its object the rapid ejection of the empty shells from the cylinder, and the rotation of the latter for that purpose automatically by the successive tilting movements of the barrel and frame; and to this end my invention consists, first, of the barrel of a revolving fire-arm having the recoil-plate made thereon at its rear end, with the chambered cylinder permanently arranged to revolve between the recoil-plate and the barrel, and to be moved away from the frame in a vertical plane passing through the axis of the barrel; and it also consists of a pawl pivoted in a recess beneath the barrel and in front of the cylinder, which engages with a ratchet on the forward end of the cylinder, the pivot being actuated by a cam on the frame at the joint. The ejector is disposed in a recess beneath the pawl extending rearwardly beneath the cylinder, and is turned upward at the rear end, so that when pushed forward its end will be forward of the flange of each shell as the cylinder is rotated to extract the shells. The ejector is forced forward into its recess, com pressing a spring at its for Ward end, by a shoulder in the frame pressing against a projection on the ejector when the cylinder and frame are brought together, and the ejector is then held by a sear; and when the barrel is tilted down the shoulder is moved out of the line of movement of the said projection, and a shoulder on the frame, at the joint, then trips the sear, allowing the spring to suddenly force the ejector rearward to eject a shell, the pawl turning the cylinder to bring each shell successively into line with the ejector for that purpose. After the sear is tripped, should a shell stick in the chamber, the ejector is forced back against the flange to start the shell by a cam on the frame, at the joint, moving against a projection on the ejector in tilting the barrel.

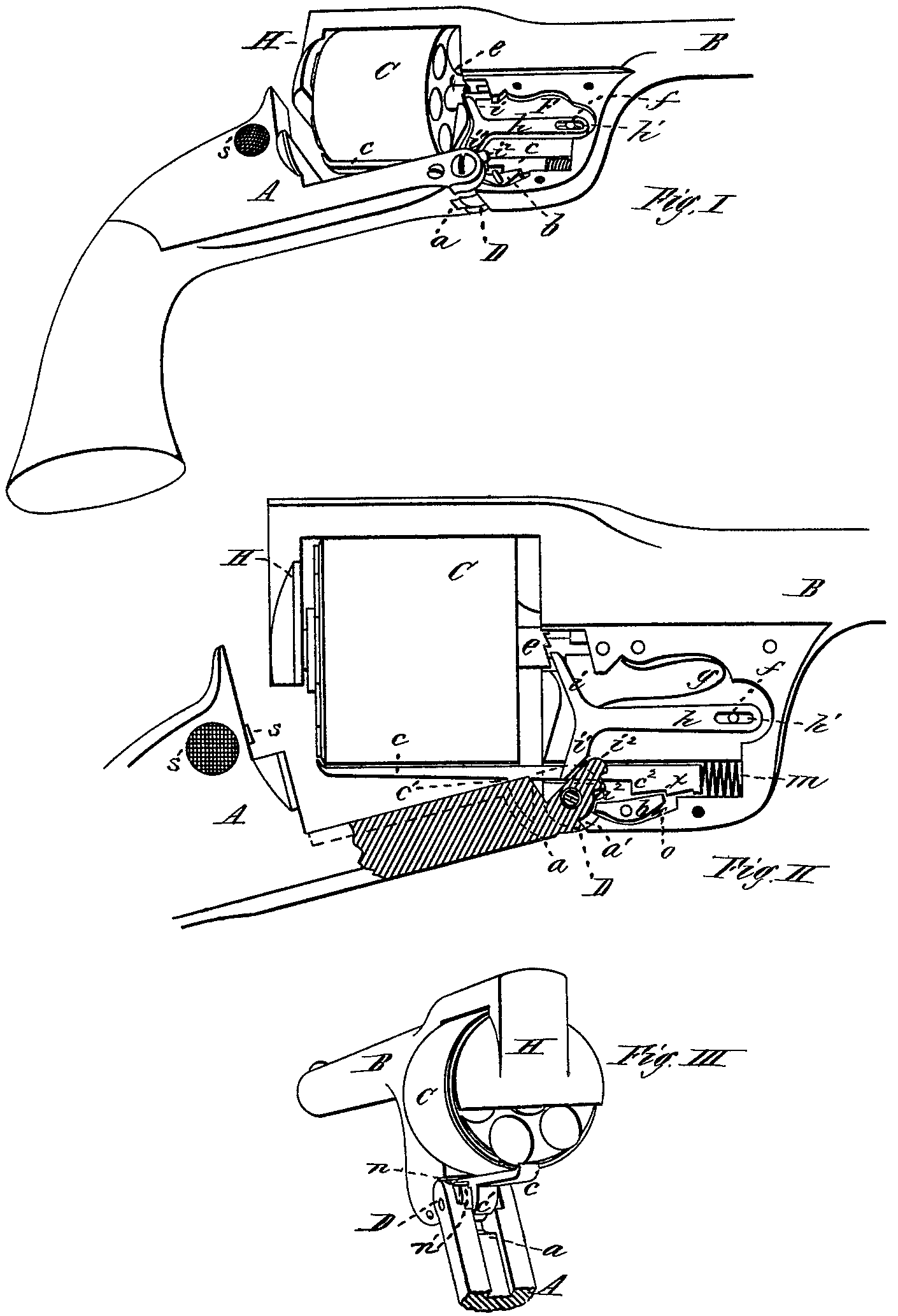

Figure I is a perspective view of a revolving fire-arm having my invention applied thereto, with the plate covering the recess in front of the cylinder removed and the barrel partially tilted. Fig. II is a side view of that portion of the arm having my invention applied thereto; and Fig. III is a perspective, view, showing the recoil-plate, cylinder, eject or, and a portion of the frame with the recess therein for the ejector.

In the drawings, A represents the frame of a revolving fire-arm, hinged to the barrel B at D. His the recoil-plate, made upon the rear end of the barrel, and C is the chambered cylinder, permanently arranged to revolve in suit able bearings between the recoil-plate and the bore of the barrel.

The cylinder is provided with a ratchet, e, on its front end, and a pawl, l, is pivoted at one end, at f, in a recess in the barrel portion of the arm in front of the cylinder, the pawl having a small slot, h, at the pivot end, to allow a slight longitudinal movement of the pawl. One arm, i, of the pawl engages with the ratchet e, and a projection, i¹, on the pawl extends down in the rear of a cam, i², made on the forward part of the frame A at the joint, by which the pawl is moved upward, a spring, g, connected with the pawl, operating to move the latter down and keep it in con tact with the cam i².

A recess is made in the lower part of the barrel portion of the arm, into which a spring, in, is placed, and the ejector c is then inserted behind and against the spring, where it is held by a pivoted rear, b, with a small Spring, o, connected there with, to throw the forward end of the sear upward against a shoulder, ac, on the ejector, when the latter is forced in. The ejector is also provided with a projection, c¹, curved on its rear side, and a shoulder, a, is made in the forward end of the frame, which, when the ejector is in its most rearward position, as shown in dotted lines in Fig. II, comes in contact with the rear curved side of the projection, when the frame and cylinder are brought together, and force the ejector for ward into position to eject a shell. A Small shoulder, a¹, is made on the inside of the frame, at the joint, to trip the sear b when the barrel is tilted down, and the end of the frame, on the inside, at the joint D, is made slightly cam-shaped at n, and when the barrel is tilted down comes into contact with a projection, n¹, on the ejector after the sear has been tripped, which forces the ejector rearward to start the shell from the chamber.

The operation of the invention is as follows: If the arm has been discharged and it is de sired to eject the shells, the button and locking-pin s are moved back and the barrel moved down. As the barrel begins to move the cam i² comes in contact with the projection i¹ of the pawl, moving the latter upward and turning the cylinder so that one of the shells is brought with its flange just in rear of the rear end of the ejector; and when the barrel is moved down so that the projection c is free to move rearward the rear end of the Sear b comes in contact with the shoulder a¹ and the sear is tripped away from the shoulder x of the ejector, and the latter is quickly moved rearward; but if the shell sticks in the chamber the cam in, Fig. III, comes in contact with the projection n¹ of the ejector and slightly forces the ejector rearward and starts the shell from the chamber, and the spring on will then eject it. The barrel is then tilted up, and the rear curved side of the projection c¹, just above its point, comes in contact with the shoulder a, and the ejector is forced forward again until the sear engages with the shoulder x of the ejector. The shells may thus be rapidly ejected as fast as the tilting movement of the barrel can be executed, and the shells are thrown entirely clear from the arm.

If desired, the spring o beneath the sear may be dispensed with, and the sear thrown into contact with the shoulder x of the ejector by a shoulder, a², on the forward end of the frame striking down the rear end of the sear; but in practice I prefer the spring.

The shoulders or cams on the forward end of the frame may all be made inside, and the sear, forward part of the ejector, and pawl be located in a recess in the lower rear part of the barrel portion of the arm and covered by a plate, or otherwise, so that all the operative mechanism may be protected from dirt and injury.

It is evident that any other arrangement of spring may be used to throw the pawl h down after its upward movement without departing from the invention.

When the ejector is thrown backward to eject a shell its movement is limited by a shoulder, c², thereon striking against the joint at the forward end of the frame.

Having thus described my invention, what I claim as new is—

1. In a revolving fire-arm, the combination of the pawl h, cam i², and spring g, arranged in front of the cylinder, as a means of automatically rotating the latter by the tilting movement of the barrel, substantially as described.

2. The combination of the ejector c, provided with the shoulder a and projection c¹, the sear b, the frame A, provided with the shoulders a and a¹, and a spring to actuate said ejector, substantially as described.

3. In a revolving fire-arm, the combination of the pawl h, cam i², with its spring, ejector c, and its actuating-Spring, Sear b, and the frame A, provided with the cams or shoulders a, a¹, and i², whereby the cylinder is rotated and the shells ejected automatically by the tilting movement of the barrel, substantially as described.

BENJAMIN F. JOSLYN.

Witnesses:

T.A. Curtis,

C. E. Buckland.