US 239634

UNITED STATES PATENT OFFICE.

FRANK H. ALLEN, OF NORWICH, CONNECTICUT, ASSIGNOR TO THE HOPKINS & ALLEN MANUFACTURING COMPANY, OF SAME PLACE.

REVOLVING FIRE-ARM.

SPECIFICATION forming part of Letters Patent No. 239,634, dated April 5, 1881.

Application filed September 8, 1880. (No model.)

To all whom it may concern:

Be it known that I, FRANK H. ALLEN, of the city of Norwich, county of New London, and State of Connecticut, have invented certain new and useful Improvements in Cartridge Extractors for Revolving Fire-Arms, a correct and comprehensive description of which is given in the annexed specification, reference being had to the accompanying drawings.

My immediate object is to produce an extracting device for revolving fire-arms which shall be extremely simple in its construction, inexpensive to make, and easily applied to revolvers as commonly constructed.

My improvements could be applied success fully to that class of revolving arms in which the cylinder and extractor are operated on a fixed base-pin, the cylinder and barrel being drawn forward and away from the extractor in the act of throwing out the empty shells; but (laying aside for the present all former systems) I prefer to apply my improvements to an arm (having a solid, continuous strap about the cylinder and a fixed barrel) from which, in the act of extracting the empty shells, the cylinder, extractor, and base-pin are removed and the shells discharged by manually forcing the extractor away from the cylinder, as I shall describe in detail in the following pages.

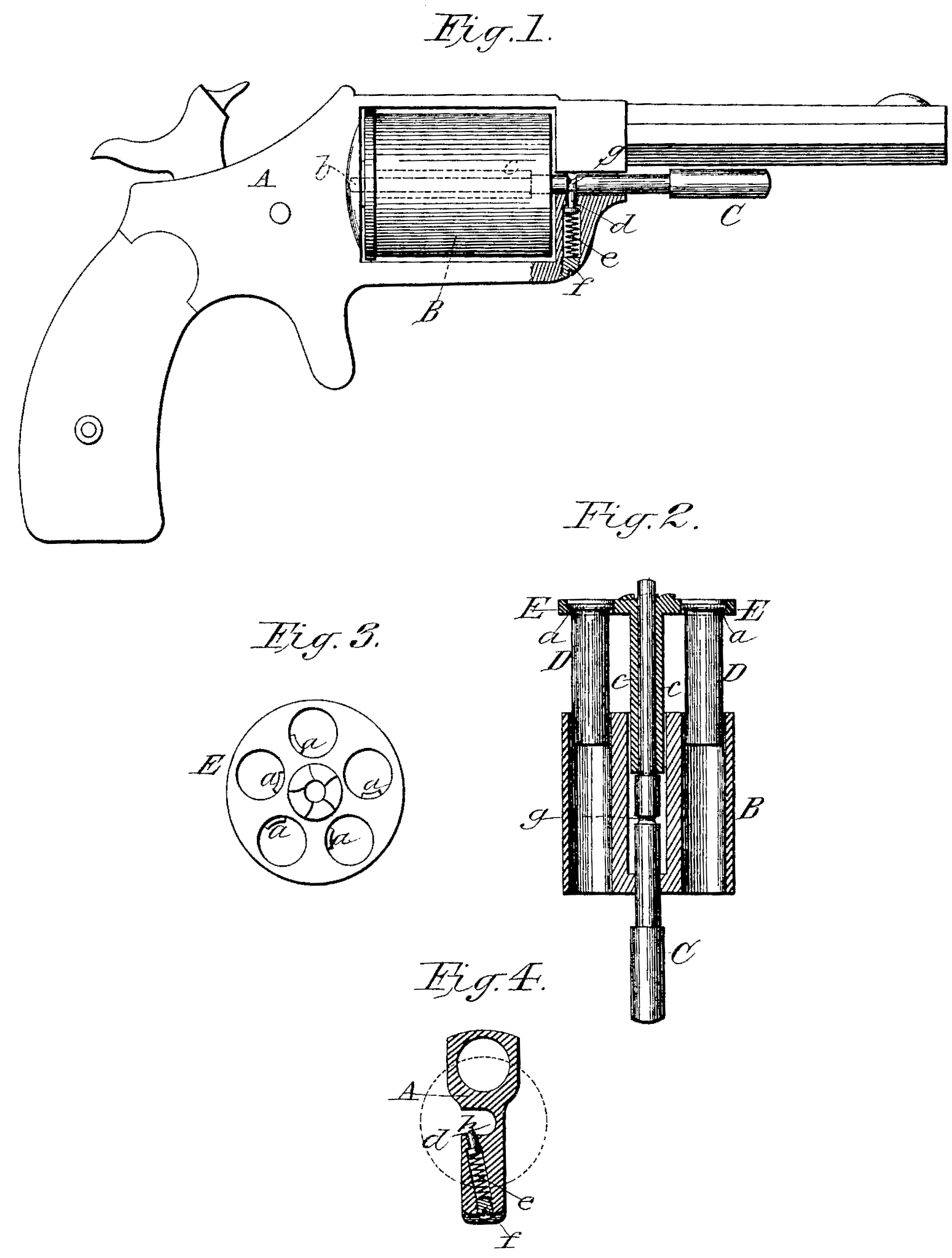

In the accompanying drawings, Figure1 rep resents a revolving arm embodying my improvements and having the cylinder, extractor, and base-pin in their respective places. Fig. 2 is a sectional view of the cylinder, extractor, and base-pin as they appear in the act of dis charging the empty shells after firing. Fig. 3 is a rear view of the extractor, showing the lugs a, which, engaging with the flanges of the cartridge-shells, withdraw the shells from the rotating cylinder after firing; also shows the ratchets which are used in revolving the cylinder in the process of firing. Fig. 4 is a front end view of the frame A, showing the device for securing the axial pin in its proper place.

The cylinder B, extractor E, and axial pin C properly belong together at all times, except when it is necessary to clean the arm. They may then be separated by withdrawing the pin C from the front, end of the cylinder and the extractor from the rear end.

The extractor E is provided with a tubular projection, c, which fills a recess in the cylinder B, as shown in Fig. 2, making the extractor E when closed, practically as rigid as if it was a part of the cylinder B.

The axial pin C passes through the cylinder and extractor, and projects from the rear of the extractor about one-eighth of an inch, or far enough to enter a recess in the frame, as shown at b, Fig. 1, so as to secure the cylinder and extractor rigidly in position while in the act of firing. The pin C is shouldered at the point where it reaches the extractor-tube c. It (the pin) is also grooved at a suitable point, g, to receive a friction-nipple, d, which is placed in the frame and held in position by the spring e and screw f.

D D represent empty cartridge-shells as in the act of ejection.

Fig. 3 shows clearly the construction of my device for withdrawing the empty shells. It consists of a metallic disk of about the same diameter as the cylinder with which it is to be used. This disk is provided with the same number of holes as the cylinder, but they are of the same size as the cartridge-heads, while the corresponding holes in the cylinder must be of the diameter of the body of the cartridge used.

At a convenient point in the bottom of each of the holes in the disk E is a lug or projection, a, which tends toward the center of the hole which it is identified with. This lug a need be only large enough to insure the strength necessary to withdraw one empty shell, and may be placed at any convenient point in the periphery of the hole to which it belongs.

In the act of withdrawing the empty shells the lug a prevents the head of the shell from drawing through the disk E so long as the cylinder holds the body of the shell; but when the disk and cylinder are forced apart, so that the body of the shell is no longer supported by the cylinder, the shell drops with a lateral motion through the hole in the disk and away from the lug a. As each lug acts independent of the rest of the series, there are practically as many extractors as there are chambers in the cylinder, yet they are all contained in one disk.

To operate my improvement, as described draw the pin C forward one-eighth of an inch, or far enough to release the pin at b. The cylinder, extractor, and pin may then be removed (with a sidewise motion) from the frame A. Holding the cylinder in an upright position, as shown in Fig. 2, press the large end of the pin C against any convenient object, or supply the necessary pressure with the unoccupied hand, when the shoulder on the pin will force the extractor-tube c and diskE away from the cylinder B, carrying with the disk E the cartridge-shells. When the shells pass beyond the reach of the cylinder they will drop freely to the ground, as before described. The head or large end of the pin C should be hardened, so that a sharp blow may be, given to it if the shells fail to start easily. Having discharged the empty shells, push the extractor-disk back to its proper place in the cylinder, reload the empty chambers, and return the cylinder to its place in the frame.

The special advantages of an arm embodying my improvements are, first, economy of time in discharging empty shells; second, a solid or unbroken recoil-shield; third, absolute protection to the heads of the cartridges when the arm is loaded and closed; and, fourth, extreme simplicity, strength, and cheapness.

I claim—

In combination with the cylinder of a revolving fire-arm, the perforated disk E, each of said perforations being provided at a suitable point in its periphery with an extracting hook or lug, a, whereby empty cartridge-shells, when held in position by the surrounding disk, may be withdrawn from the cylinder, as and for the purpose specified.

FRANK. H. ALLEN.

Witnesses:

Willis W. Clarke,

G. W. Hamilton.