Germany 80156

PATENTSCHRIFT

— Nr 80156 —

KLASSE 72: Schusswaffen und Geschosse.

DANIEL BAIRD WESSON in SPRINGFIELD (Massach., V. St. A.).

Revolver mit einem die seitlich ausschwingbare Trommel geschlossen haltenden Auswerfer.

Patentirt im Deutschen Reiche vom 28. März 1894 ab.

Die vorliegende Erfindung bezieht sich auf diejenigen Revolver, bei welchen die Patronentrommel seitlich aus dem Trommelbügel herausgeschwungen werden kann zum Zwecke der Entfernung der Patronenhülsen. Die Erfindung besteht darin, dafs der zur Entfernung der Patronenhülsen dienende Auswerfer gleichzeitig mit einer federnden Nase zur Befestigung der Trommel in Stellung in dem Bügel ausgerüstet ist.

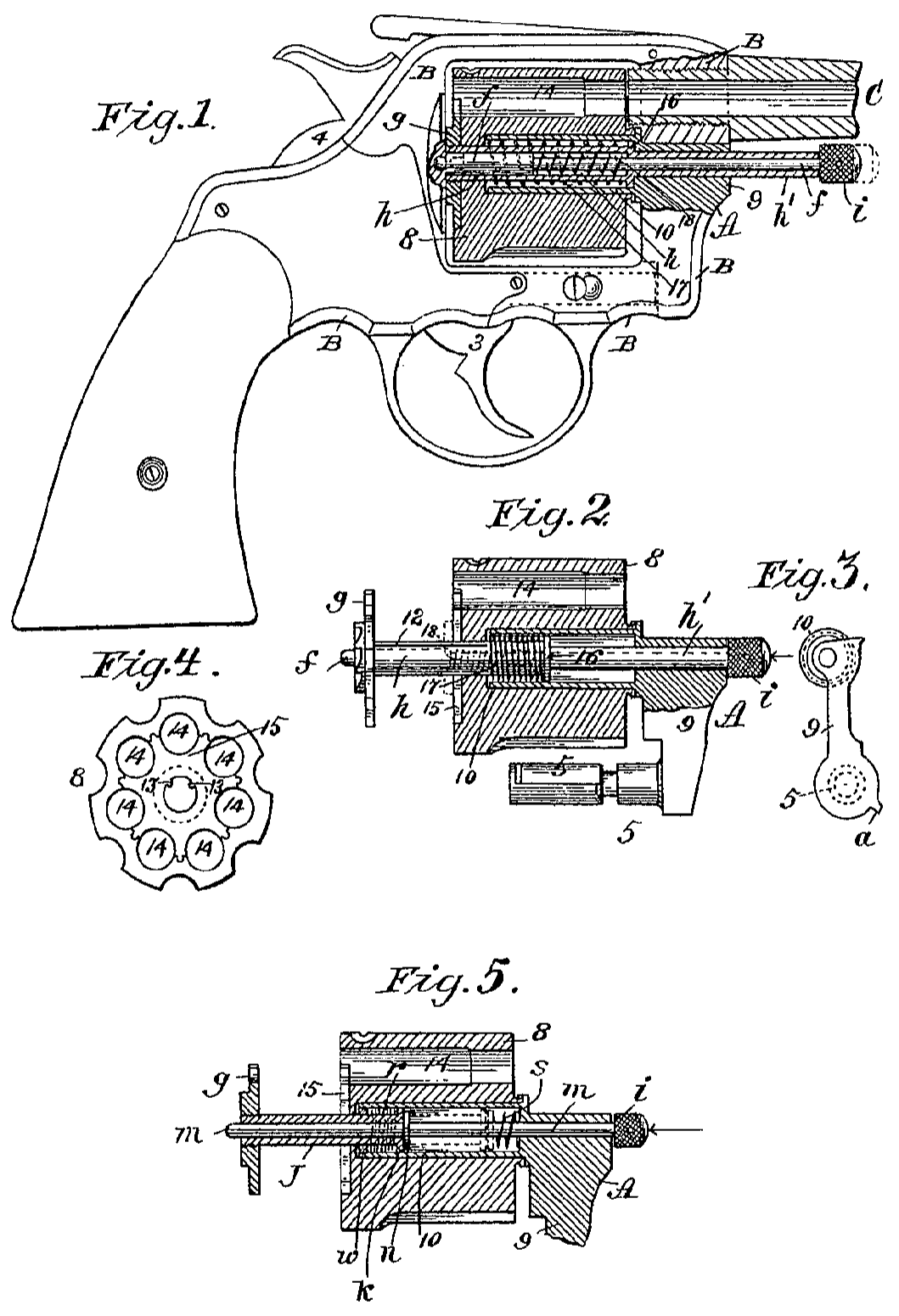

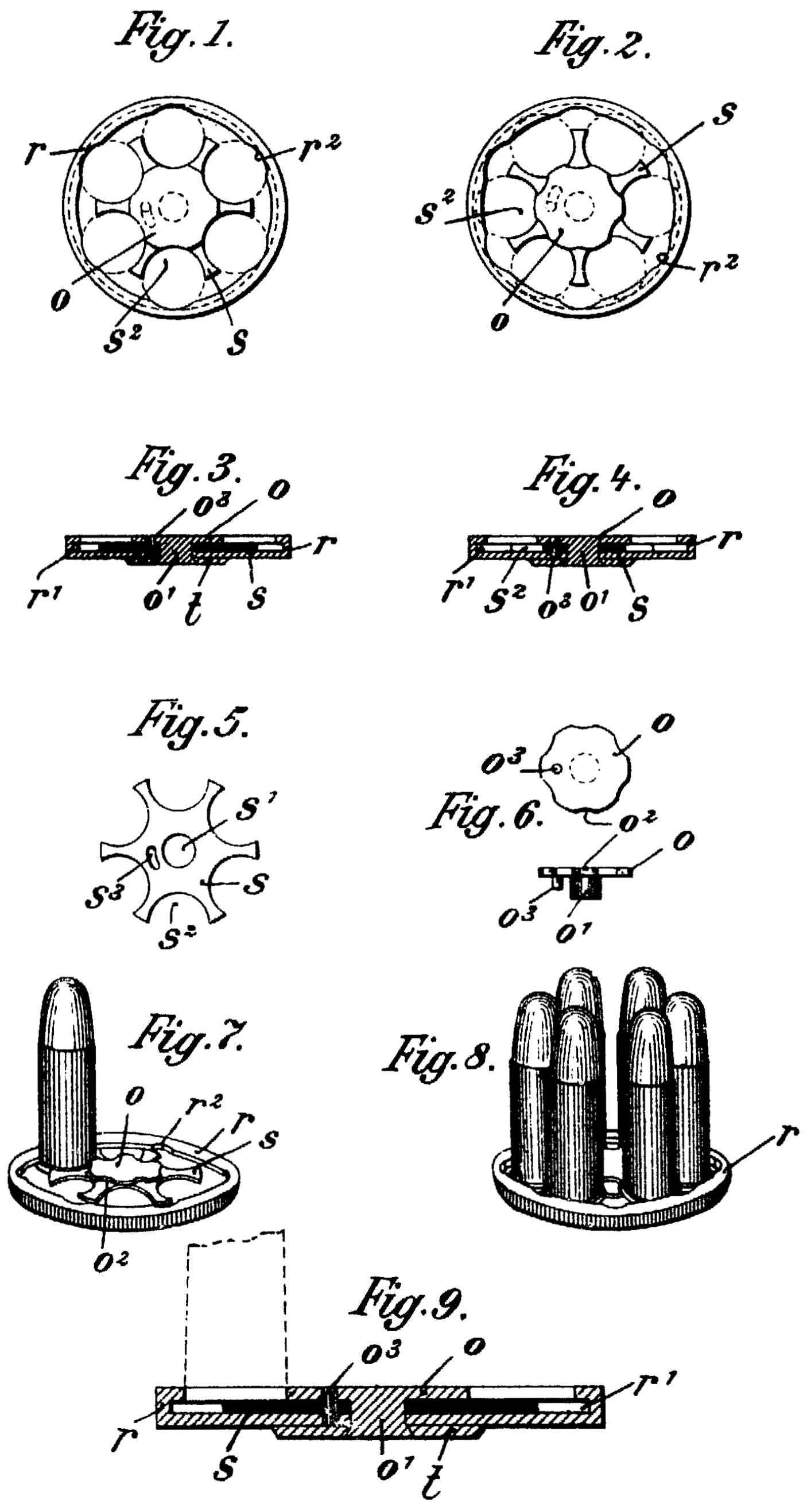

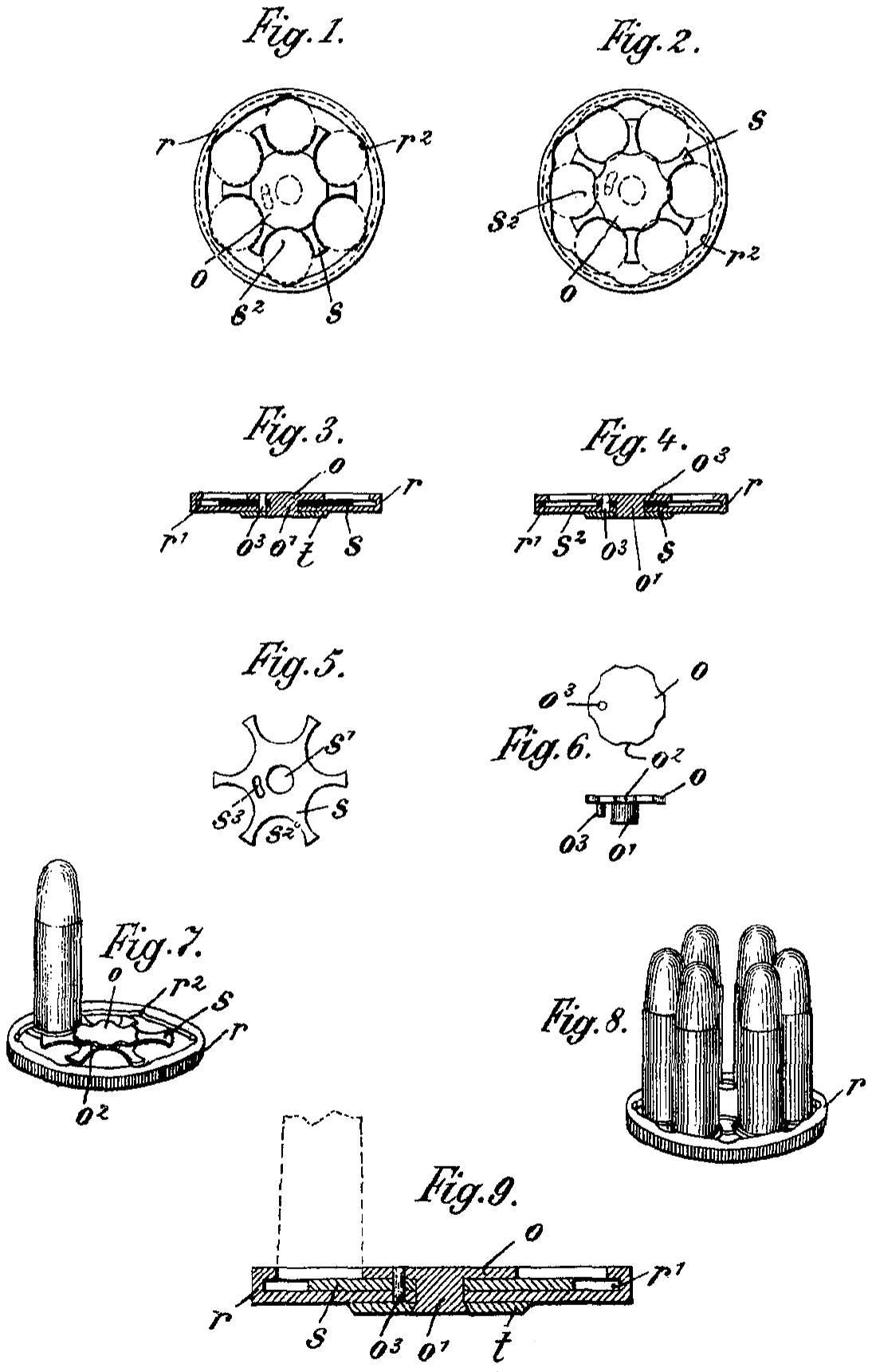

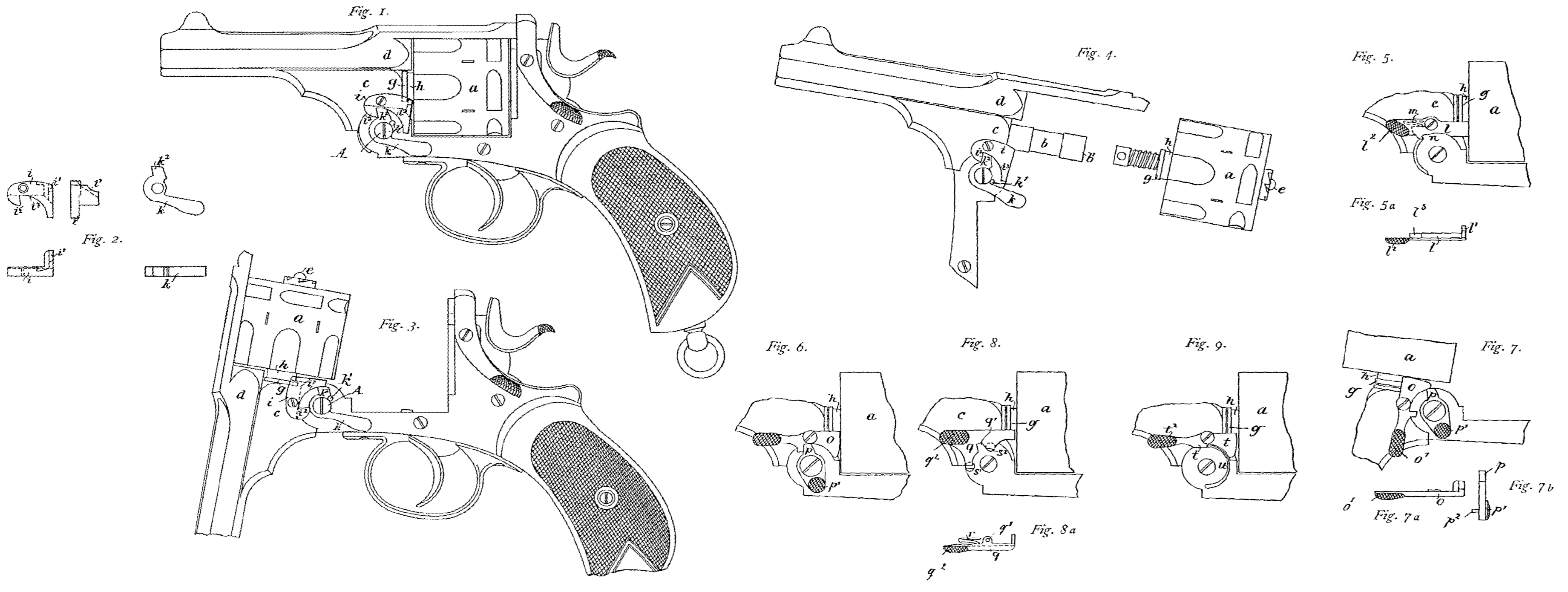

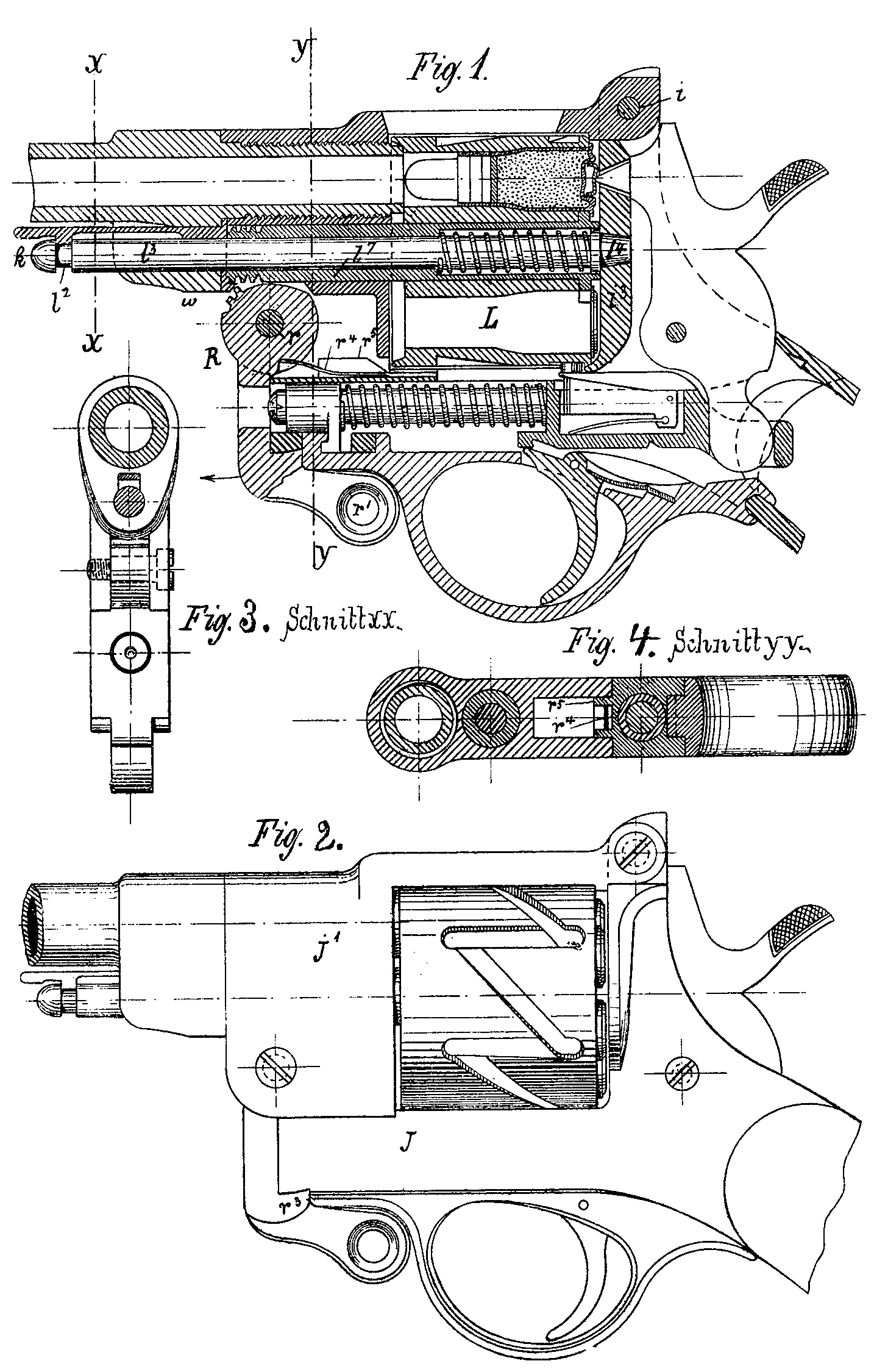

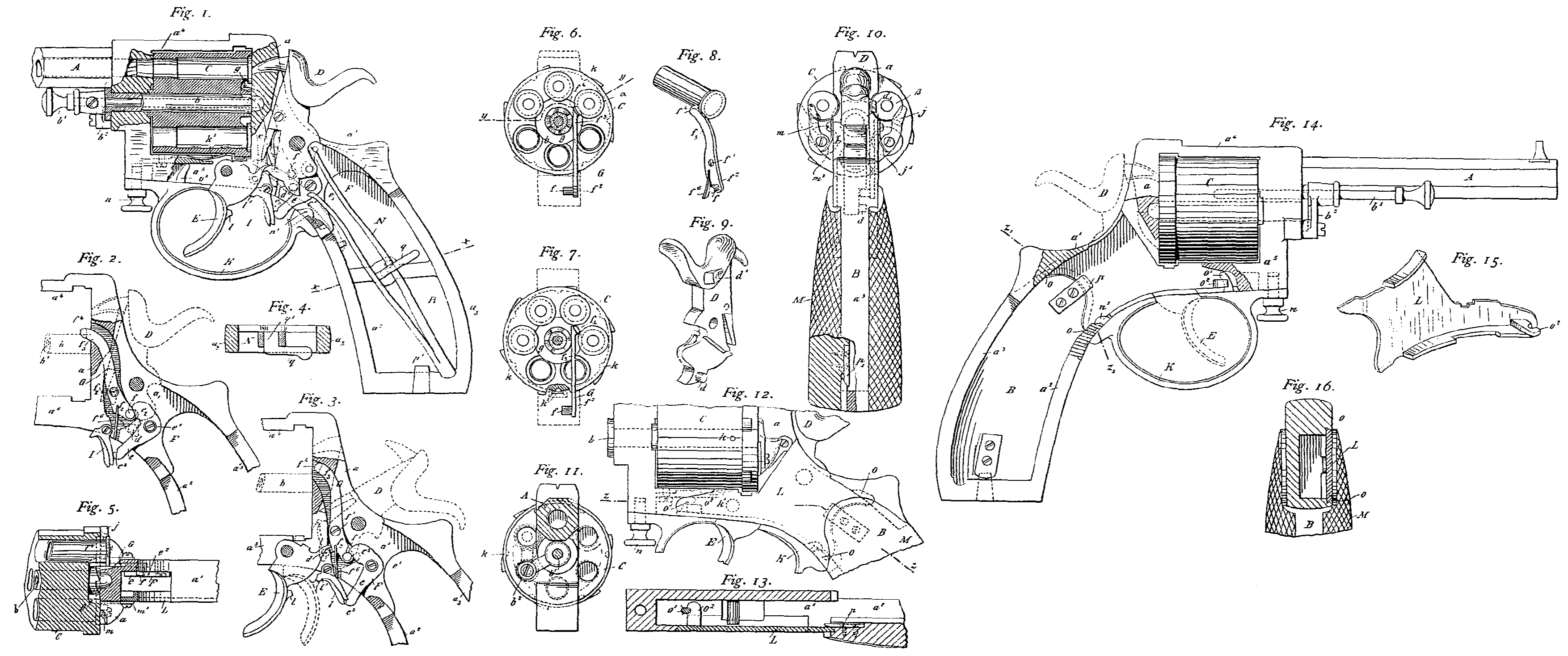

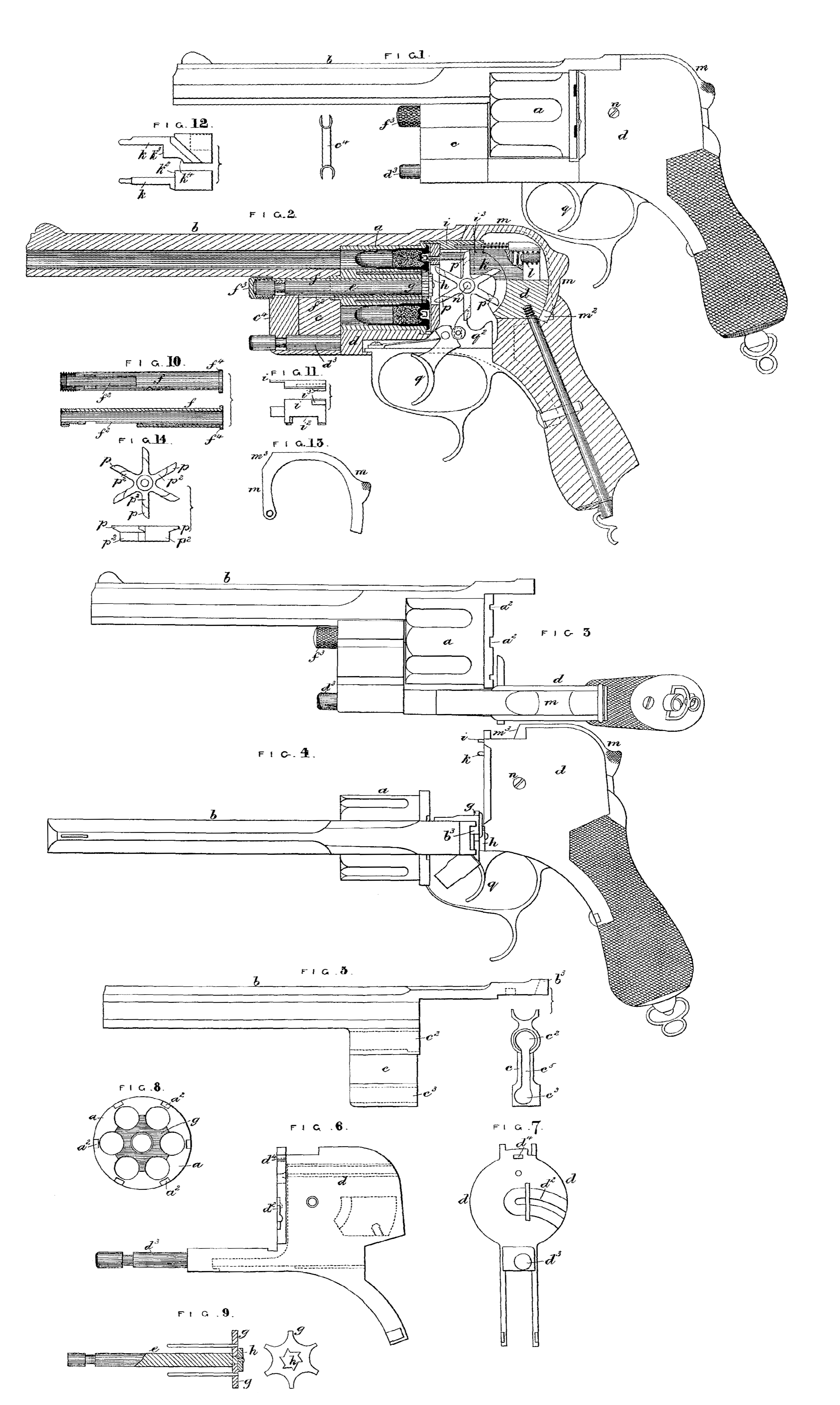

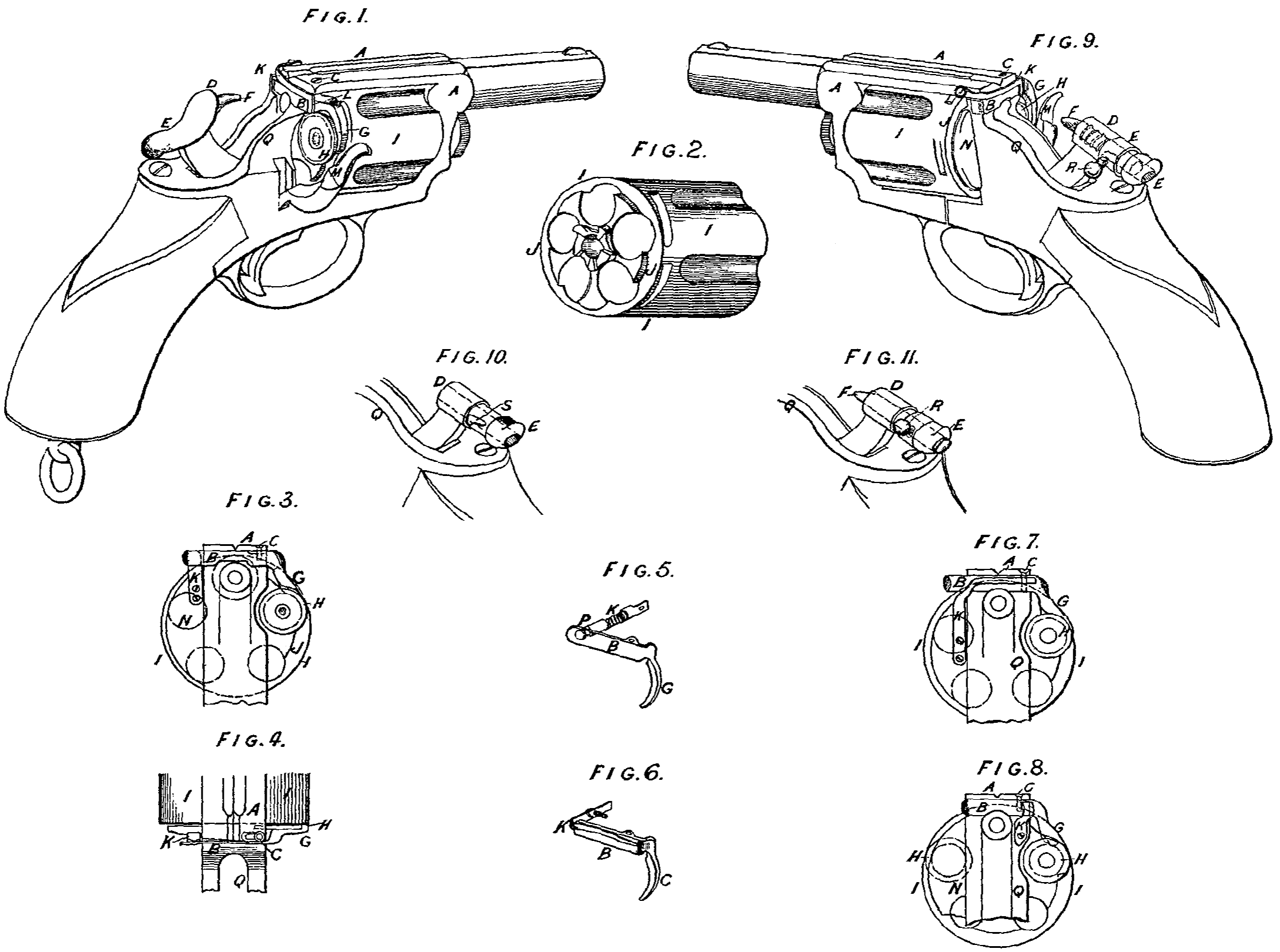

Auf der beiliegenden Zeichnung ist

Fig. 1 eine Seitenansicht, theilweise im Verticalschnitt eines nach Art vorliegender Erfindung ausgeführten Revolvers,

Fig. 2 .ein Verticallängsschnitt durch die Trommel und den Bügelarm,

Fig. 3 eine Detailansicht des Bügelarmes,

Fig. 4 eine Endansicht der Trommel und Stofsplatte und

Fig. 5 ein Verticallängsschnitt durch die Trommel bei abgeänderter Ausführungsform der Erfindung.

A bezeichnet den Revolverkolben, B den Trommelbügel, C den Lauf; 4 ist der Hammer, welcher in der bekannten Weise von dem Drücker 3 aus bethätigt wird. Die Patronentrommel 8 dreht sich auf der hohlen Achse 10, welche in dem beweglichen Arm 9 des vorderen Theiles y des Trommelbügels B befestigt ist. Der Arm 9 ist mit dem im unteren Theile des Bügels B drehbar gelagerten Arm 5 fest verbunden und kann sammt der Trommel und Trommelachse aus dem Bügel B seitlich herausgeschwungen werden.

Die zur Entfernung der Patronenhülsen nach erfolgtem Ausschwingen der Trommel dienende

Platte g ist ringsherum mit den Patronenkammern 14 entsprechenden Ausschnitten versehen und hat zwischen den letzteren die bei 15 in Fig. 4 ersichtliche Form. Dieselbe ist an dem hinteren Ende der röhrenförmigen Stange h befestigt und in der Endfläche der Trommel versenkt. Der Kolben h wird vor Drehung in der Trommel dadurch geschützt, dafs die Vorsprünge 13, Fig. 4, der letzteren in die Längsnuthen 12 des ersteren eingreifen. Der Kolben h liegt in der hohlen Achse 10 der Trommel und wird hinten durch eine entsprechende Bohrung der letzteren und vorn durch die durch eine Bohrung des Armes 9 hindurchgehende, verkleinerte, röhrenförmige Verlängerung h¹ horizontal geführt.

Am vorderen Ende des Kolbens h ist ein Bund 16 vorgesehen, gegen welchen sich eine Spiralfeder 17 legt, deren anderes Ende sich gegen einen ringförmigen Ansatz in der Trommelbohrung stützt. Die Feder 16 hat das Bestreben, die Platte g gegen die Trommel 8 zu halten. In dem Rohr h h¹ liegt die Stange f, deren Hintertheil. dem inneren Durchmesser des Rohres h entspricht, während das Vorderende in die Verlängerung h¹ hineinpafst und mit einem Knopf versehen ist. Am Hinterende der Stange f befindet sich ein Zapfen, welcher in eine entsprechende Vertiefung der Rückstofsplatte des Revolvers durch Wirkung der Spiralfeder 18 hineingedrückt wird und die Trommel vor dem Laufe festhält. Um die Trommel seitlich nach aufsen zu bewegen, zieht man den Knopf i nach vorn und entfernt somit den Zapfen f von der Vertiefung der Rückstofsplatte, schwingt dann den Arm 9 und damit die Trommel um den Zapfen 5 und drückt den Knopf i nach hinten, wodurch die Platte g ebenfalls nach hinten geschoben wird und diePatronenhülsen von den Kammern 14 entfernt. Hierauf drückt die Feder 17 die Platte g in Stellung gegen die Trommel zurück.

In der in Fig. 5 veranschaulichten abgeänderten Ausführungsform: wird das Rohr J, welches die Platte g trägt, an dem vorderen Ende mit einem Bund k. versehen, während die hohle Achse 10 mit einer ringförmigen Mutter w, deren innerer Durchmesser dem äufseren Durchmesser des Rohres J entspricht, verschlossen wird. Die Stange m ist überall von gleichem Durchmesser und mit einem Bund » versehen. In ausgeschobener Stellung der Platte g wird die zwischen der Mutter w und dem Bund k liegende Spiralfeder zusammengepreist und bewirkt nach erfolgter Freigabe des Knopfes i die Zurückschiebung der Platte g gegen die Trommel 8; in dieser Stellung hält die Feder S die Stange m mit dem Bund n gegen den Bund k, so dafs das hintere Ende der Stange m stets in der Vertiefung der Rückstofsplatte des Revolvers durch Federdruck gehalten wird, wenn die Trommel sich in Stellung vor dem Laufe befindet.

Patent-Anspruch:

Ein Auswerfer für Revolver mit seitlich ausschwingbarer Patronentrommel, dadurch gekennzeichnet, dafs das hintere Ende der Auswerferstange (16 bezw. m) in eine die Auswerfplatte (g) tragende Hülse (h bezw. J) gegen den Druck einer Feder (18 bezw. S) zurücktreten bezw. gezogen werden kann, um in oder aufser Eingriff mit einer Rast des Revolverbügels gebracht zu werden.