US 144814

UNITED STATES PATENT OFFICE.

DAVID WILLIAMSON, OF GREENVILLE, NEW JERSEY.

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 144, S14, dated November 18, 1873; application filed November 12, 1873.

To all whom it may concern:

Be it known that I, DAVID WILLIAMSON, of Greenville, in the county of Hudson and State of New Jersey, have invented certain new and useful Improvements in Revolving Fire-Arms; and I do hereby declare that the following is a full, clear, and exact description thereof, that will enable others skilled in the art to Which it appertains to make and use the same, reference being had to the ac companying drawings and to the letters of reference marked thereon, which form a part of this specification, in which—

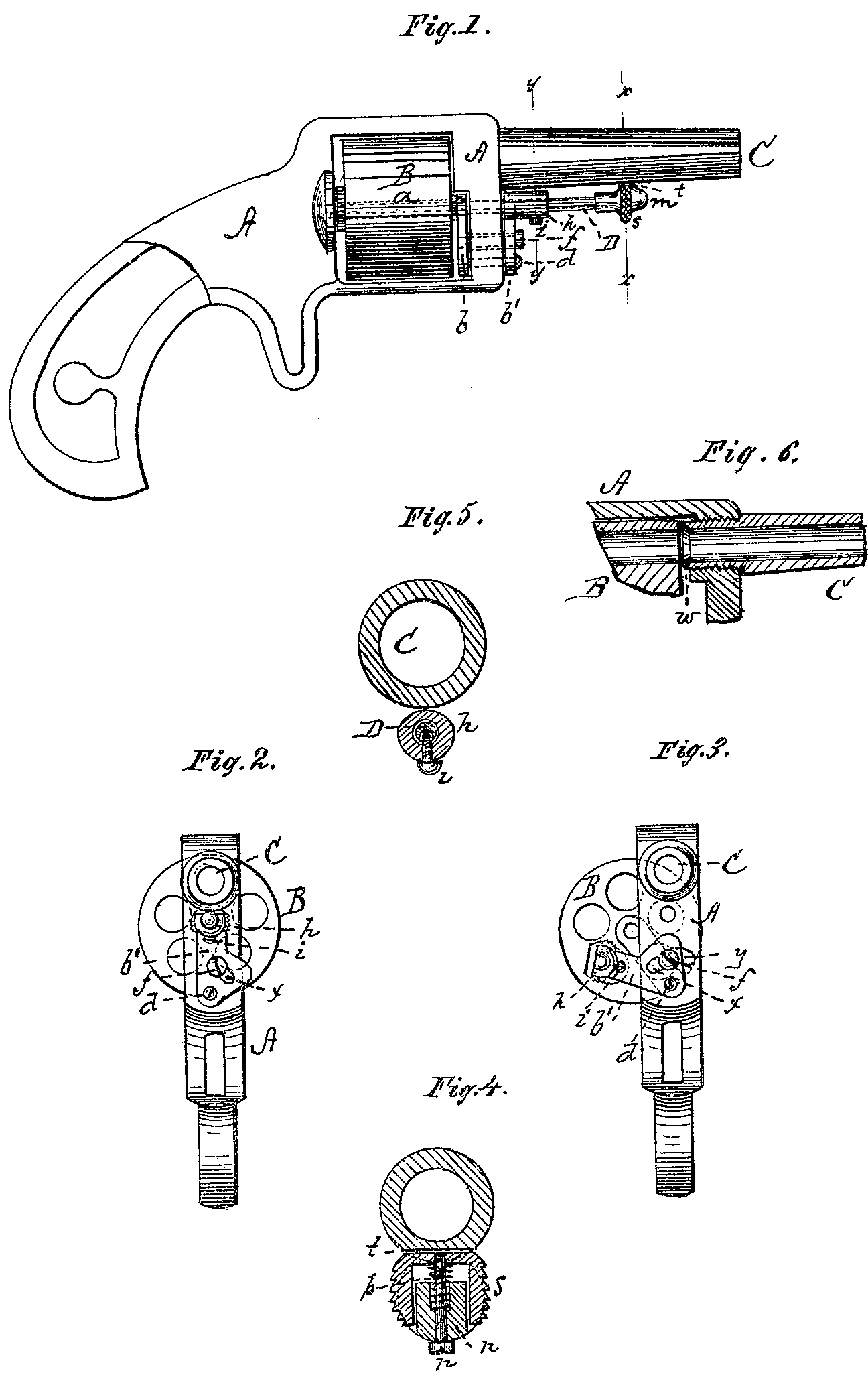

Figure 1 is a side view of so much of a revolving fire-arm as will illustrate my invention. Fig. 2 is a front-end view of the same, showing the cylinder in position. Fig. 3 is a similar view, showing the cylinder turned to one side for loading. Fig. 4 is a transverse section through the line x x of Fig. 1. Fig. 5 is a similar section through the line y y of Fig. 1; and Fig. 6 is a longitudinal section, showing a part of the barrel and cylinder.

My invention relates to an improvement in that class of revolving fire-arms in which the cylinder is turned to one side for removing the empty shells and for the insertion of cartridges; and the nature of my invention consists in so arranging the cylinder and the central shaft or rod upon which it revolves that when the cylinder is thrown to one side said rod or shaft may be used, without being detached from the fire-arm, as a ramrod to remove the empty shells. It also consists in the construction of the mechanism whereby said central shaft or rod is held in position, and also in forming the rear end of the barrel with a knife-edge, all of which will be hereinafter more fully set forth.

In the accompanying drawing, A represents the lock-frame, cast of metal in one piece, with an opening for the insertion of the cylinder B, and having the barrel C permanently secured to its front end. Through the center of the cylinder B passes a tube, a, the front end of which is attached to an arm, b. This arm is pivoted at its lower end by a bolt, d, at the front end of the opening in the frame A, said bolt d being passed inward from the front of the frame, and its outer end projecting beyond the frame, as shown. Upon this outer end of the bolt d is pivoted a plate, b, which is held to the front of the frame by means of a headed bolt or screw, f. This screw passes through a slot, ac, in the plate b’, and through a slot, y, in the front of the frameA, and screws into the arm b. The slot, y and screw f thus limit the movement of the arm b upon its pivot d, and hence the lateral movement of the cylinder is also limited thereby. The slot y is so arranged that when the screw f is against one end thereof the cylinder will be directly in the center of the frame, in proper position for being revolved by the lock mechanism, and when the cylinder is thrown out, bringing the screw f to the other end of the slot y, the cylinder will be in proper position for loading. At the upper or outer end of the plate b’ is formed a shortforward-projecting tube, h, through which passes a shaft or rod, D. This shaft is grooved longitudinally upon one side from near one end to near the other, and a set-screw, i, is screwed through the tube h, so that the inner end thereof will enter said groove in the shaft, and thus prevent the shaft from being entirely with drawn from the tube, while it is allowed to be moved for a certain distance through the tube. The slot a in the plate b is so arranged that when the cylinder B has been placed in position in the center of the frame A, as above de scribed, by moving the plate in the same direction until the end of the slot a strikes the screw f, the shaft or rod D may be pushed in through a hole in the frame and pass through the central tube a, its inner end entering a hole in the back part of the frame, thereby holding the cylinder in its place to be revolved by the lock mechanism and fired.

Though the shaft D does not, in reality, form a bearing upon which the cylinder revolves, it still forms its central support, around which the cylinder is revolved, the immediate bearing, however, being the tube a, through which said shaft passes.

By pulling out the shaft or rod D as far as it will go, the cylinder B may be thrown a certain distance to one side, as above described, which movement also turns the plate b’ with the shaft D in the same direction; but, on ac count of the slot ac, the plate b’ maybe turned just as much farther as the length of said slot. This will allow of the shaft D being pushed inward successively through the chambers in the cylinder B, for the purpose of removing the empty shells, thus obviating the necessity of having a separate ramrod or of detaching the central shaft from the fire-arm.

Upon the outer end of the shaft D is formed a head, m, which is grooved upon the top and two sides, as shown in Fig. 4. From the bot tom of the head m is then passed upward a screw or bolt, n, which is surrounded by a spiral spring, p, within a recess in the head, and the end of the bolt is screwed into a three-sided slide, s, placed in the grooves mentioned. The spring p throws this slide upward, so as to enter a notch, t, made in the under side of the barrel C, when the shaft D has been pushed in to hold the cylinder in place, thus locking the shaft in position and preventing its accidental displacement. The slides is easily pulled down when the shaft is to be drawn out.

The rear end of the barrel C, which projects within the cylinder opening in the frame A, is made flaring in the bore, and terminates in a sharp or knife edge, c, as shown in Fig. 6, so that when the cylinder revolves this knife-edge will clean the cylinder of all adhering gum or dirt.

Having thus fully described my invention, what I claim as new, and desire to secure by Letters Patent, is—

1. The combination, with a cylinder which swings laterally for the purpose of loading, &c., of a vibrating slotted arm or plate, substantially as herein described, whereby the lateral movement of the center-pin and rammer is limited and brought in position, for the purpose set forth.

2. The plate b’, having slot a and bolt or screw f, in combination with arm b and cylinder B, substantially as and for the purpose specified.

3. The combination, with the cylinder B, tube a, and arm b, of the slotted plate b, the frame A having slot y, bolt or screw f, and shaft D, all constructed substantially as and for the purposes herein set forth.

In testimony that I claim the foregoing I have hereunto set my hand.

DAVID WILLIAMSON.

Witnesses:

Marselus Wauters,

Harry C. Scott.