Britain 20321

№ 20,321 A.D. 1889

Date of Application, 18th Dec., 1889

Complete Specification Left, 13th Feb., 1890—Accepted, 3rd May, 1890

PROVISIONAL SPECIFICATION.

Improvements in Revolvers and other Breech-loading Small-arms

I, Edwinson Charles Green, Gun & Revolver Maker, 87 High Street, Cheltenham, Gloucestershire, do hereby declare the nature of this invention to be as follows:—

My invention for improvements in breech-loading revolvers refers to an improved lock mechanism, also a method of securely bolting the barrel & breech action of same, also a method for preventing the fouling of the cylinders of revolvers, also a plan for lightening revolver & rifle barrels, also to covering the handles of revolvers with cork or similar material.

To securely lock the barrels & body together of what are known as drop-down revolves,”which are fitted with a dove-tailed top projection breech support,”— I one on each side — corresponding recesses are cut in the rear sides of the revolver frame, a pin is fitted through the lever link fastening & the frame to hold it in position.

On the upper part of the lever link is formed a projection, which when the hammer is down is made to abut on or over the top or head of the revolver hammer, so that until the hammer is half cocked, the breech cannot be opened.

Or, instead of the foregoing, a projecting stud can be left on the head of the hammer, and a corresponding recess for it formed in the head of the link lever fastening, or a stud can be formed on the lever link fastening, & a corresponding hole for its reception formed in the head of the hammer.

This form of lever link support can also be made on revolvers fitted with rebounding locks, but when so preferred, I use that form of double-action half. cocking lock which cannot rebound while the trigger is held back; the revolver can only be fired by the head of the hammer passing underneath the top bar of the lever link, thereby more securely locking the revolver during each discharge than can be done when the lever is not supported by the hammer, but so soon as the trigger is released the hammer rebounds, & the breech is left free to be opened.

To open with one motion my revolver with an ordinary lock, mount on the pin on the link fastening a suitable thumb-piece, & upon its being pressed down, the upper or link part is drawn back, & the barrel left free to be opened at the breech. In either case this lever link fastening can be made self-closing by the aid of a spring, or the spring can be dispensed with.

For the lock-work of what are known as hammerless revolvers, I mount in the head of the revolver, a revolving striker head, shaped with suitable grooves, & fitted with a guide actuated in the customary manner by a spring and trigger. In front of the striker head, & in connection with it, a ratchet or stud formed collar head is carried through the face of the action, & is made io engage in or against suitable recesses formed on the rear of the cylinder, so that when the lock is cocked, the cylinder is made to rotate by the studded collar, & held in position during the firing of the cartridge.

I make this lock a double-action one by the aid of a sear & an outside cocking arm, on which the tumbler of the lock is mounted, & by the aid of a suitable rod, one end being mounted underneath & against the main spring, & the other carried forward to the trigger or cylinder lifter, enables me to dispense with a separate sear or trigger spring, & I make the lock rebounding ,by the aid of a separate spring acting upon the trigger or striker head, or hy the aid of the mainspring acting upon either, or a separate arm, or by lengthening the lower part of the mainspring, so as to make it rest on the trigger or its lifter, the trigger both rod & sear spring can be dispensed with. Upon the outside cocking lever being pulled; the mainspring is compressed, bringing the lock to fall cock, or by pulling the trigger only, the lock is full cocked, & carried beyond its turn, & so forces the inside rotating striker-head forward to deliver its blow-on the-cartridge, & at the same time hold in position either the link or bolt, of the breech fastening.

Or, instead of the foregoing form of breech fastening, I fit in a hole which I form in the head of the frame, & against the top projection of the frame, also through the rear-of the barrel projection,*either an oblique or a vertical bolt, capable of motion. This holt is made self-acting by the aid of a spring. A projecting thumb piece is formed on the side of this bolt, or a separate thumb lever can be fitted to operate it, & when preferred a sliding self-acting stop is fitted to lock the vertical or oblique bolt, & prevent it being withdrawn until the slide is pushed back.

The barrel of the revolver is hinged to the forward part of the frame in the customary manner, & upon pressing down the thumb-piece of t re bolt, the barrel & cylinder can be tilted & made free for loading, or ejecting the discharged cartridge cases; upon closing the breech, the bolt is forced upwards by the spring in the hole formed in the rear of the barrel projection,-thereby securely locking the barrel and frame together.

The hammer is conveniently arranged in connection with the bolt so that it is impossible to fire the revolver unless the bolt is in its secure position, also when preferred, I fit a stop catch to keep the bolt down when the revolver is open for loading.

l make the revolver so that it can be cocked in the customary manner by the trigger, also by the hammer in the centre of the frame, or by a lever mounted on the side of the revolver.

By this latter plan, the lock mechanism is better preserved from the effects of out-side fouling.

To prevent the cylinder of my revolver from becoming foul or difficult to rotate after firing, I shape the central forward end of the cylinder where it is mounted on the centre rod, either concave or inclined.

As an additional precaution, I also form on the centre rod spiral grooves, & drill one or more holes in the base of the barrel, whereby at the moment of discharge the gas, & residuum of the cartridge may be deflected, & the fouling of the revolver avoided.

As a further protection to the efficient: use of my revolver from the insidious effects of sand & dust, I fit a leather or metal cover over the cylinder & barrel, which when preferred can be retained on the’ revolver during the act of firing.

When it is desirable to make revolver or rifle barrels light, & retain their maximum amount of strength, I form the outsides in a poly groove shape.

With the object of giving a firm grip to my revolver, & prevent its slipping in the hand when being fired, I fit on the handle a covering of cork or similar material.

Dated this 16th day of December 1859.

EDWINSON CHARLES GREEN.

COMPLETE SPECIFICATION.

Improvements in Revolvers and other Breech-loading Small-arms.

I, Edwinson Charles Green, Gun & Revolver Maker, 87 High Street, Cheltenham, Gloucestershire do hereby declare the nature of my invention for Improvements in Revolvers and other Breech-loading Small-arms and in what manner the same is to be performed, to be particularly described and ascertained in and by the following statement:—

My invention has reference to what are known as drop-down breech-loading hammer and hammerless revolvers, & consists of the arrangements or combination of parts as hereinafter described for-securely locking together the barrels and breech or frame of revolvers and pistols.

Also to a simple form of hammerless revolver lock.

Also to a method for preventing the cylinder from being fouled during the discharge of the said revolvers.

And to the use of cork on the handle of revolvers to give a firm grip to the user.

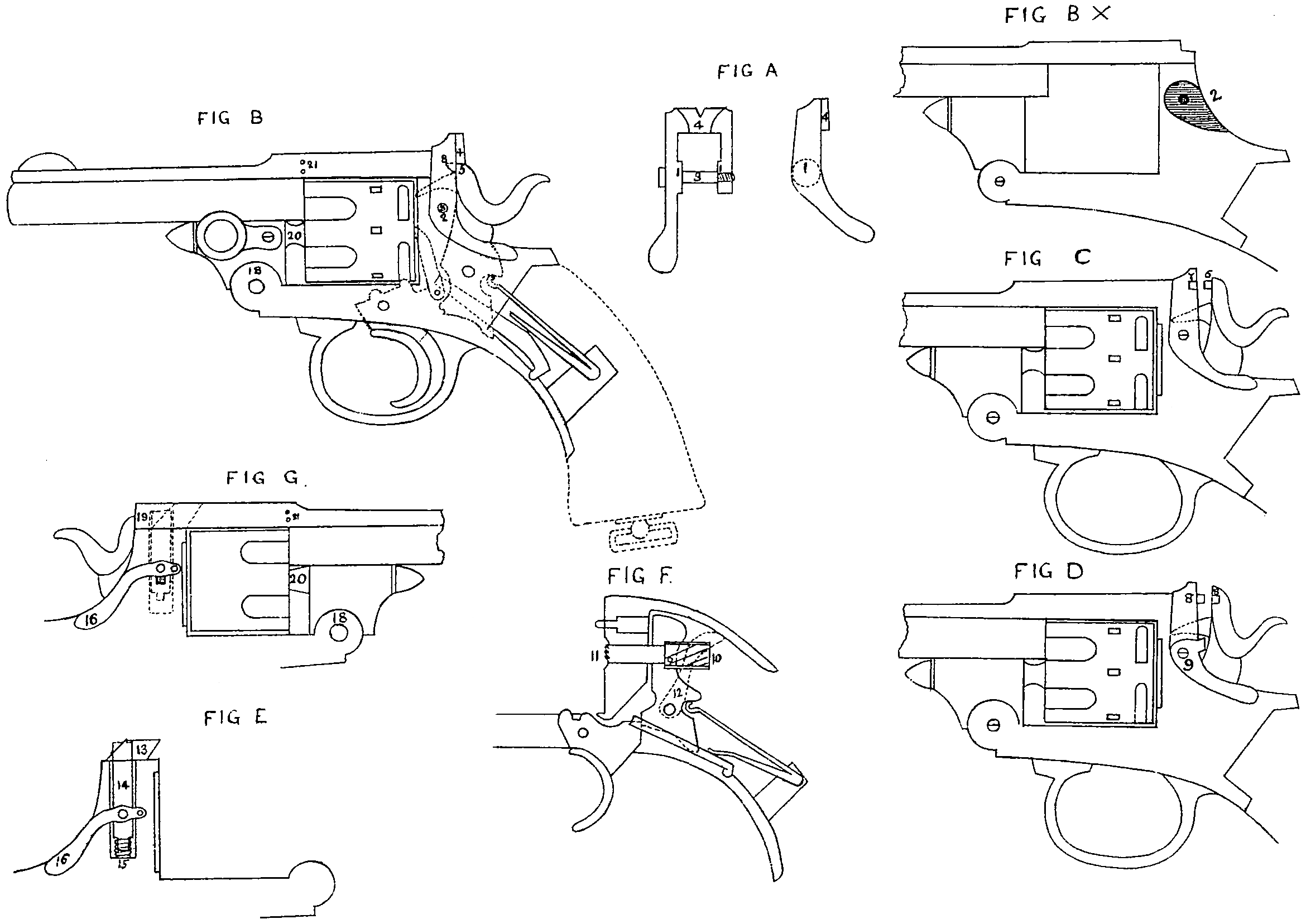

To securely lock the barrels and body together of what are known as drop-down revolvers, which are fitted with a dove-tailed top projection breech support, I form on the inside of the vertical part of my lever link fastening, two raised bosses, Fig. A 1-1; corresponding recesses are cut in the rear sides of the revolver frame, Fig. B & BˣX 2-2.

A pin is fitted through the lever link fastening & frame to hold it in position, Fig. A & B-3.

On the upper part of the lever link is formed a projection, Fig. A & B 4-4-4, which when the hammer is down is made to abut on or over the top or head of the revolver hammer 5, so that until the hammer is half or full cocked, the breech cannot be opened.

Or instead of the foregoing plan of lever link support, a projecting stud is formed on the head of the hammer 6, Fig. C, and a corresponding recess formed for it in the head or cross bar of the link lever fastening 7, or a stud can be formed on the lever link top bar D 8, and a hole formed for its reception in the head of the hammer, or a recess is formed underneath the lever link, Fig. B 8, into which the head of the hammer engages before the revolver can be fired.

These forms of lever link supports can also be fitted on revolvers which are provided with rebounding locks, bat when so preferred, I use that form of half-cocking lock which cannot rebound while the trigger is held back, similar to the lock arrangement shown in Fig. B. The revolver can only be fired after the head of the hammer has passed underneath the top bar of the lever link— and acting as a support of locking arrangement thereto— thereby more securely locking the revolver during each discharge than can be done when the lever is not supported by the hammer; as soon, however as the trigger is released the hammer rebounds, & the breech is left free to be opened.

To open with one motion my revolver with an ordinary lock (not rebounder) I mount on the pin, 3, of the link fastening a suitable thumb-piece Fig. D 9, & upon its being pressed down the upper or link part is drawn back & the barrel left free to be opened at the breech. In either case this lever link fastening can be made self-closing by the aid of a spring, or the spring can he dispensed with.

For the lockwork of what are known as hammerless revolvers, J mount in the frame of the revolver, a revolving centre-rod, operated by the hammer, shaped with suitable grooves, Fig. F 10, & fitted with a guide actuated in the customary manner by a spring and trigger. In front of the striker head and in connection with it, a ratchet or stud formed collar head, 11, is carried through the face of the action, & is made to engage in or against suitable recesses formed on the rear of the cylinder, so that when the lock is cocked, the cylinder is made to rotate by the studded collar, 11, & held in position during the firing of the cartridge. I make this revolver a double-action one by the aid of an outside cocking arm, 12, mounted on a tumbler hammer, In other respects the lockwork is of the customary revolver pattern.

Or instead of the foregoing A & B form of breech fastening, I fit in a hole formed in the head of the frame, & against the vertical top projection Fig. E 13, of the frame, also through the rear of the barrel projection, either an oblique or vertical bolt, capable of motion, Fig. E14. This holt is made self-acting by the aid of a spring, 15. A projecting thumb-piece is formed on the side of this bolt, 16, or a separate thumb-piece can be fitted to operate ii, also when preferred a sliding self-acting stop is fitted to lock the vertical or oblique bolt, & so prevent it being withdrawn until the slide is pushed back.

The barrel of the revolver is hinged to the forward part of the frame in the customary manner 18-18, & upon pressing down the thumb-piece 16— 16, of the bolt, the barrel & cylinder can be tilted, & made free for loading, or ejecting the dis-charged cartridge cases; upon closing the breech the bolt is forced upwards by the spring 15 into the hole formed in tie rear of the barrel top projection, thereby’ more securely locking the barrel & frame together, 19.

The hammer is conveniently arranged in connection with the bolt so that it is impossible to fire the revolver unless the bolt is in its secure position; also when preferred, I fit a stop catch to keep the bolt down when the revolver is open for loading.

I make the revolver so that it can be cocked in the customary manner by the trigger, also by the hammer, in the centre of the frame, or by a lever mounted on the side of the revolver; by this latter plan the lock mechanism is better preserved from the effects of outside fouling.

To prevent the cylinder of revolvers from becoming foul or difficult to rotate after firing, I shake the central forward end of the cylinder where it is mounted on the centre rod either concave or inclined, 20-20.

As an additional precaution, L also form on the centre rod spiral grooves, & drill one or more holes near the base of the barrel 21-21, whereby at the moment of dis-charge the gas and residuum of the cartridge may be deflected, & the fouling of the revolver avoided.

As a further protection to the efficient use of revolvers from the insidious effects of sand and dust I fit a leather or metal cover over the cylinder & barrel, which when preferred can be retained on the revolver during the act of firing.

When it is desirable to make revolver or rifle barrels light, & retain their maximum amount of strength, I form the outsides in a polygroove shape.

With the. object of giving a-firm grip to my revolver, & prevent its slipping in the hand when being fired, I fit on the handle a covering of cork or similar material.

Having thus particularly described and ascertained the nature of my said invention, I would have it understood that while I do not confine myself to the precise details herein before described, what I claim substantially as novel is

Firstly. The combination of the head of the hammer, or a projection thereon, passing underneath when down, and abutting against a part of the top bar of the lever link, or a projection thereon.

Secondly. The method by which— by the aid of the vertical bolt— the barrel and breech of revolvers are securely bolted.

Thirdly, A shell or covering of leather or metal to protect revolvers from becoming clogged by sand or dust.

Fourthly. The ratchet or stud-fronted grooved centre rod with the hammerless lockwork, combined for the purpose of revolving the cylinder.

Fifthly. Covering the handle of revolvers with cork.

In witness whereof, I the said Edwinson Charles Green have hereunto set my hand, February 12th 1890.

E. C. GREEN.