USA 239676

UNITED STATES PATENT OFFICE.

GEORGE W. SCHOFIELD, OF THE UNITED STATES ARMY.

CARTRIDGE-HOLDER FOR REVOLVERS.

SPECIFICATION forming part of Letters Patent No. 239,676, dated April 5, 1881.

Application filed July 22,1880. (No model.)

To all whom it may concern:

Be it known that I, GFORGE W. SCHOFIELD7 an officer of the United States Army, have invented a new and useful device which may be called a “Combined Cartridge Holder and Loader,” or a “Multi-Loader;” and I do hereby declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same, reference being had to the accompanying drawings, and to letters and figures marked thereon, which form a part of this specification.

The objects of my invention are to provide a safe and convenient means of holding any given number of cartridges in proper position for, and of quickly and simultaneously placing said cartridge’s in, the chambers of a many-chambered fire-arm.

To this end my invention consists of a cartridge-receiver, a cartridge-holder fastened or suspended in said receiver, and a compressor or expander for contracting the spring-holder, so as to release the cartridges and allow them to drop fully into the chambers of an arm in the act of loading.

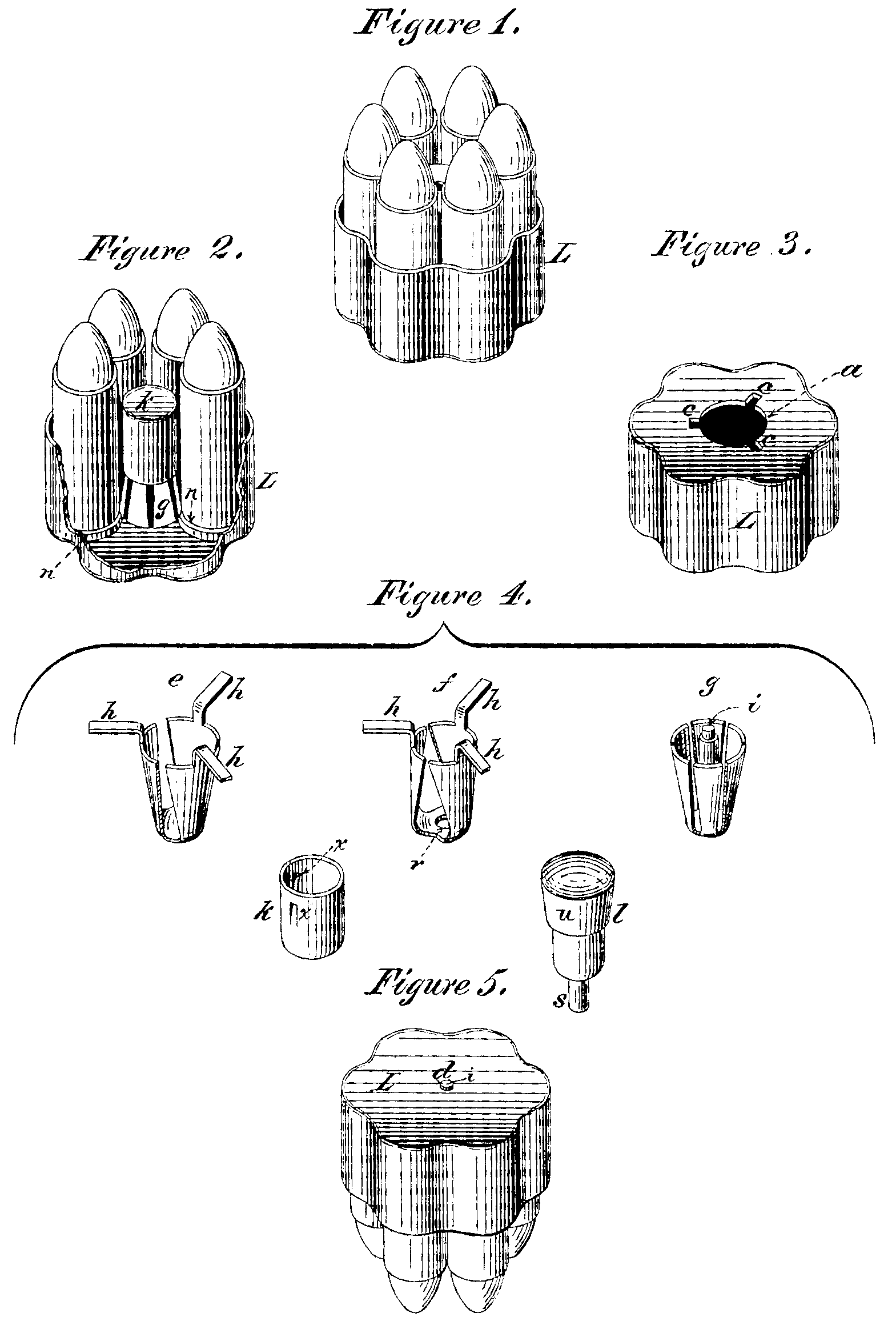

Figure 1 is a perspective view of the carrier and loader with the cartridges in their places ready for use, but inverted, so as to more plainly show the cartridges. Fig. 2 is a perspective view of the same with a portion of the receiver L broken away and two cartridges left out, showing the spring-holder g, Figs. 2 and 4, in position, and also the manner and means of its holding the cartridges in the receiver L until operated on by the compressor k, Fig. 4, to release them. In this drawing the loader is also inverted for manifest reasons. Fig. 3 is a perspective view of the receiver L, with a large central hole, a, in its top or cap end and three short slots, c c c, at equal distances around said large hole a. This form is devised for the holder with arms h h h, as shown in Fig. 4, e and f; but to use the holder e it is not absolutely necessary to have the large hole a, as the slots c c c can be punched through the solid head of the receiver L, the arms h h h passed through said slots, and then be bent down to position. Fig. 4 is a view of the spring-holder in three slightly differing forms, as shown in e, f, and g, and of the compressor k and the expander l, for operating the holder to release the cartridges in loading said cartridges into the chambers of a fire-arm. Fig. 5 is a perspective view of the combined carrier and loader charged with cartridges, and standing in the proper position for carrying in a cartridge-box or other appendage ready for use. It also shows a small hole, d, with the end i of the pin g, Fig. 4, slightly through it, which is for the purpose of securing the holder g inside of and fast to the receiver L by riveting, pinning, or by means of screw-threads.

A receiver, L, is made of any suitable material, corrugated so as to give a number of cavities around its wall, to correspond with the number of cartridges required by any given arm. The mode of forming this receiver would most naturally be by drawing sheet metal through a die of proper construction for this purpose.

A spring-holder, Fig. 4, e f g, is formed of any suitable elastic metal, and is divided, throughout a large portion of its length, by spaces, into any desired number of limbs, for the purpose of providing for its contraction and expansion, to hold the cartridges in the receiver L, and for releasing them therefrom when desired. Each limb may be made to hold two or more cartridges, or there may be one limb to each cartridge. In the drawings, Fig. 4, e and f show three limbs each, while g shows six. This spring-holder may be kept from dropping out of the receiver L by any convenient and suitable means, two modes being shown in Fig. 4, e and f having three arms, h h h, while g has a center-pin, i, for this purpose. The arms h h h are passed through slots c c c in the receiver, and are then bent down so as to rest on the top surface of said receiver, or a large hole, a, Fig. 3, and the slots, c c c may be at the same time cut or punched, and then the holder e or f can be put into the receiver after the arms h h h are bent to place, as shown.

The end of the center-pin i, Fig. 4, g, is passed through a smaller hole, d, Fig. 5, and the holder is kept in place by riveting or pinning, or by screw-threads cut on the end of said pin i and in the hole d. In either case a space equal to or a little greater than the thickness of the cartridge-rims is left between the upper ends of the limbs of the spring-holder and the inside surface of the receiver’s top, for the purpose of enabling the holder to retain the cartridges in place by their rims until released by contraction of the holder in the act of loading. The most convenient mode of forming this spring-bolder would probably be by cutting any sufficiently elastic metal into proper shape and then drawing it into proper form io through a die.

A compressor or expander, Fig. 4, k and l, is made preferably of brass, copper, or tin, and by the process of drawing in a die of the required dimensions to release the cartridges from the receiver L, by an upward movement of itself caused by pressure in- the act of loading. The compressor k, Fig. 4, is prevented from dropping off of the holder e and g, Fig. 4, by bending in the ears x x after it is put onto the bottom of said holder; or a pin may be passed through it for the same purpose. The expander l, Fig. 4, is likewise held from moving or falling entirely out of the holder f, Fig. 4, by a pin passing through its smaller end s and the ends of the pin left slightly projecting, or by turning a rim on said small end s. This is not considered essential, however, as, by the position in which the loader is to be carried and by friction, it being necessary to press it tightly into place, this expander can hardly be moved from its position in the holder, except in the motion of loading, and that does not push it entirely out. In making the holder for use of the expander l it is given a diameter at its upper end, as substantially shown in Fig. 4, f, slightly less than that of the circle between the cartridge-heads as they stand in the receiver L. The one for use of the compressor k, as substantially shown in Fig. 4, e and g, is made of a diameter slightly greater than that of the circle of the space between the bodies of the cartridges as they stand in the receiver L. Both of these operate to hold and to release the cartridges by their spring action. The holder for use of the expander l is also given a hole, r, in its bottom end for the small end s of the expander l to pass through.The beveled surface u in l, Fig. 4, serves to expand the holder f and cause it to retain the cartridges, and, when pushed upward by pressure in loading, to release them by the spring action of the holder f.

The manner Of Using my multi-loader is as follows: The cartridges being in the loader and they may be placed there at the factory, or by the person who is to carry and use it, as may be desired- it should be carried in a box or other receptacle, with the balls downward, as shown in Fig. 5. The ends of the projectiles may rest on a flat surface or in indentations made in wood, or, if thought necessary, in shallow holes. To load a fire-arm, the chambers being first uncovered, take the multi-loader in one hand, while the weapon is held or steadied by the other. Start the cartridges into the chambers until the compressor or expander comes in contact with the part of the arm lying between the chambers, and then press down on the loader, when the cartridges will be released and will drop fully into their places. Should any of the cartridges, on account of fouling or rust in the chambers, fail to enter fully, they can be readily pressed to place by a touch of the fingers. This failure to fully enter will not occur when both the arm and the cartridges are in proper condition. This downward pressure on the loader, as mentioned above, forces the compressor or expander upward on the holder, or partially out of the same, by which the diameter of said holder is reduced, thus freeing the cartridges and causing them, by their weight, to drop the remaining distance into the chambers. The pressure required is but slight, as is also the downward movement to secure the perfect release of the cartridges.

Having thus described my invention what I claim as new, and desire to secure by Letters Patent, is-

1. A cartridge package or holder and multi-loader combined, consisting of a shallow cup, a spring-retainer to hold cartridges in the cup or receiver, and a compressor or expander for releasing the cartridges from the receiver, substantially as shown and described.

2. The carrier or holder and loader described, consisting of a corrugated cup, of sheet metal or other suitable material, combined with the central retaining device, having spring-arms to extend over the flanges of cartridges, thereby holding said cartridges in the receiver, as set forth.

3. The carrier or holder and loader described, consisting of a corrugated cup, of sheet metal or other suitable material, combined with the central retaining device, having spring-arms, to extend over the flanges of cartridges, and thus hold the cartridges in place, and a cup, as k, to compress the spring-arms, as described.

4. The carrier and loader described, consisting of a corrugated cup or receiver, combined with a central retaining device, having spring-arms to hold the cartridges by their flanges, and a cup, as k, to contract the spring-arms, in combination with the magazine of a fire-arm, substantially as described.

G. W. SCHOFIELD.

Attest:

WILLIAM H. JOHNSTON, F. MALLIDAY.