US 16683

UNITED STATES PATENT OFFICE.

SAML, COLT, OF HARTFORD, CONNECTICUT.

IMPROVEMENT IN MANY-CHAMBERED ROTATING-BREECH FIRE-ARMS.

Specification forming part of Letters Patent No. 16,683, dated February 21, 157.

To all whom it may concern:

i. Be it known that I, Samuel Colt, of Hartford, in the State of Connecticut, have made a new and useful Improvement in Many-Chambered Rotating-Breech Fire-Arms; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings, making part of this specification, in which—

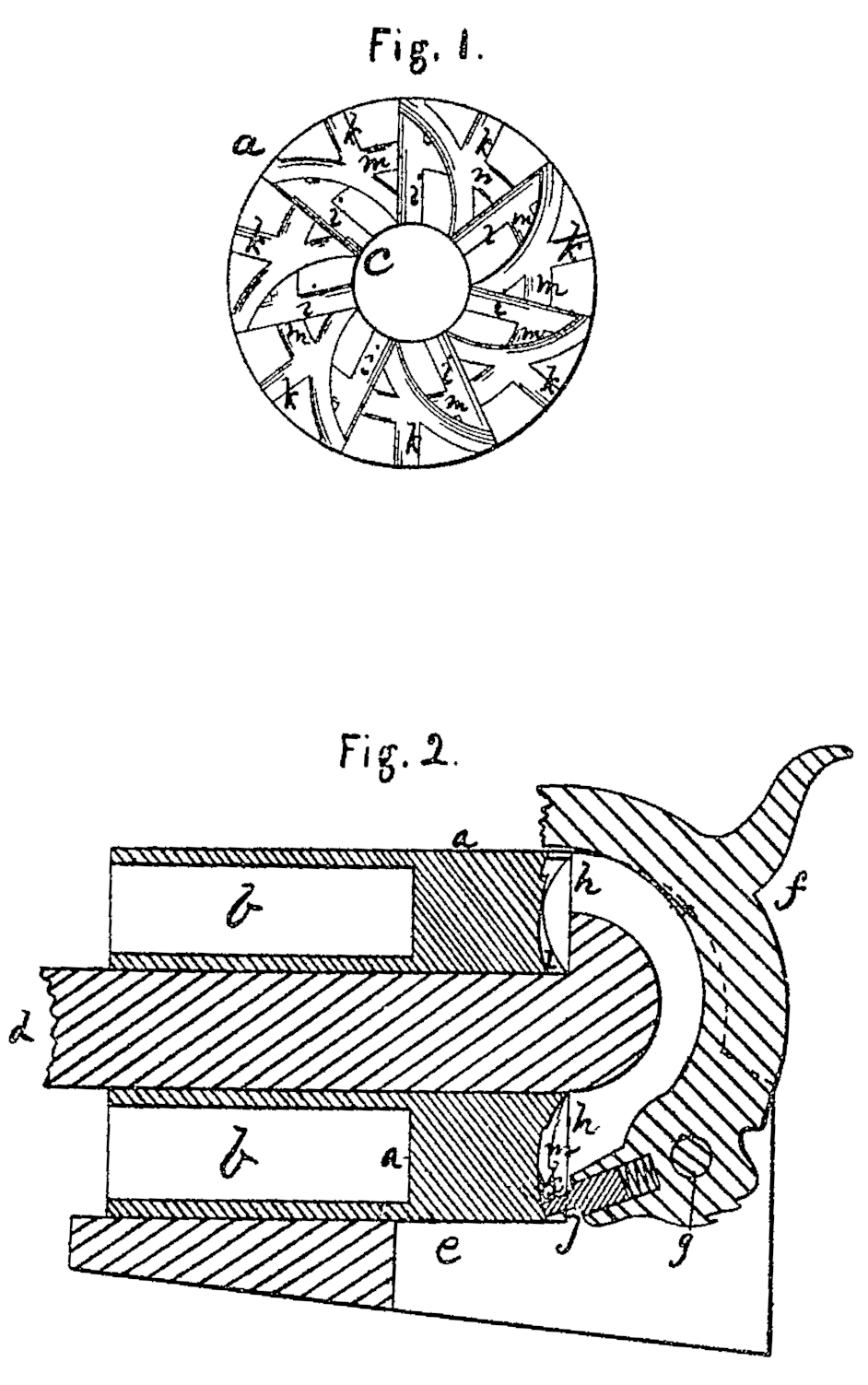

Figure 1 represents an elevation of the rear end of the rotating breech, and Fig.2 a longitudinal section of the rotating breech connected with the shield-plate and hammer.

The same letters indicate like parts in both figures.

My said invention relates to a method of rotating the many-chambered breech by the act of cocking; and it consists in making grooves in the surface of a spherical concavity in the rear end of the rotating breech, to be acted upon by a spring driving pin or bolt receiving motion from the cock or some equivalent part of the lock, so that by the vibration of the said driving pin the breech shall be turned or rotated to bring the several chambers successively in line with the barrel by the act of cocking, and held in line with the barrel during the discharge.

In the accompanying drawings, a represents the rotating breech, with a series of parallel chambers, b, formed around the central bore, c, which fits and turns freely, but accurately, on a central pin, d, secured to the lock plate or frame e in any suitable manner. The cock or hammer f turns on a fulcrum-pin, g, in the lock plate or frame, and strikes on the nipples in the usual or any appropriate manner, not necessary to describe, as this makes no part of my invention. The backend of the rotating breech is recessed, as at h, forming an annular groove or concavity concentric with the central bore, every radial section of which in the plane of the axis of the breech will be a segment of a circle, whose center is the axis of vibration of the cock. In the face of this recess there is a series of radial grooves, i, one for each chamber, and another series of equal number of curved or diagonal grooves, each of which extends from near the outer end of one radial groove to the inner end of the next, and the outer end of the curved grooves is deeper and the inner end not so deep as the radial grooves. The outer end of a round driving pin or bolt, i, is fitted to work in these grooves, and its body, which is square, is fitted to work in a recess in the body of the cock, with a spring of any suitable kind interposed to keep the pin against the face of the grooves.

From the foregoing it will be seen that in the act of cocking the pin or bolt j, running in one of the curved or oblique grooves, will turn the breech until the pin falls into the next radial groove, there stopping the rotation of the breech, and that in the act of discharging the said pin or bolt will run along the radial groove, retaining the breech in the same position by reason of the radial direction of this groove, so that there can be no danger of shifting the position of the breech during the discharge; and it will also be seen that the difference in the depth of the grooves in connection with the spring, which tends to force out the pin or bolt, will insure the running of the pin or bolt in the curved or diagonal groove in the act of cocking and in the radial groove in the act of discharging. There is another series of radial grooves, k, extending from the oblique grooves, so that after the hammer has been brought to the half cock, and the rotating breech thereby turned about half the distance of one of the spaces between the chambers, the pin or bolt can then run into the short radial grooves to permit the hammer to be let down and rest on the metal surface of the breech, there to rest in safety until the arm is to be used; and from the main radial and the oblique grooves short inclined planes or concentric grooves m are formed, extending from the bottom of the main grooves to the surface of the concavity, so that when the hammer is elevated to half-cock and there held the said pin or bolt will yield to the inclined surfaces of the lateral grooves, and thus permit the breech to be brought around by hand.

I am aware that many-chambered breech in repeating fire-arms has been rotated to shift the chambers and the several chambers in succession held in line with the barrel during the discharge by means of a driving-pin receiving motion from the cock and , working in longitudinal and diagonal grooves made sometimes on the outer surface of the said breech and sometimes on the inner surface of the central bore; and I am also aware that the breech has also been thus operated by the driving-pin working in radial and diagonal grooves made on the rear flat face thereof, but when so made, the groove being formed in a flat surface and the cock which imparts motion to the driving-pin working on a fulcrum or central pin, it was necessary either to connect the driver with the cock by a joint-pin or to give the driver a considerable end-play to compensate for the difference between the curvilinear motion which the driver would receive from the cock if directly attached to it and the flat surface in which the grooves are formed. These defects I have avoided by making the radial and diagonal grooves in the rear end or face of the rotating breech, which is so concaved that the surface thereof will correspond with the curvilinear motion of the driver vibrating on the axis of the cock. I do not therefore wish to be understood as making claim broadly to the method of rotating the breech by a driving-pin working in grooves, but to limit my claim to the special improvement which I have made thereon.

What I claim as my invention, and desire to secure by Letters Patent, is—

Making the series of grooves to be acted upon by the driving-pin to rotate and hold the breech in a concavity in the rear end of the rotating breech, substantially as and for the purpose specified.

SAM. COLT.

Witnesses:

Chas. M. Keller,

Wm. H. Bishop.