US 221171

UNITED STATES PATENT OFFICE.

ANDREW HYDE, OF HATFIELD, MASSACHUSETTS

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 221,171, dated November 1, 1879; application filed March 31, 1879.

To all whom it may concern:

Be it known that I, Andrew Hyde, of Hatfield, Hampshire county, State of Massachusetts, have invented an Improvement in Revolving Pistols, of which the following is a specification.

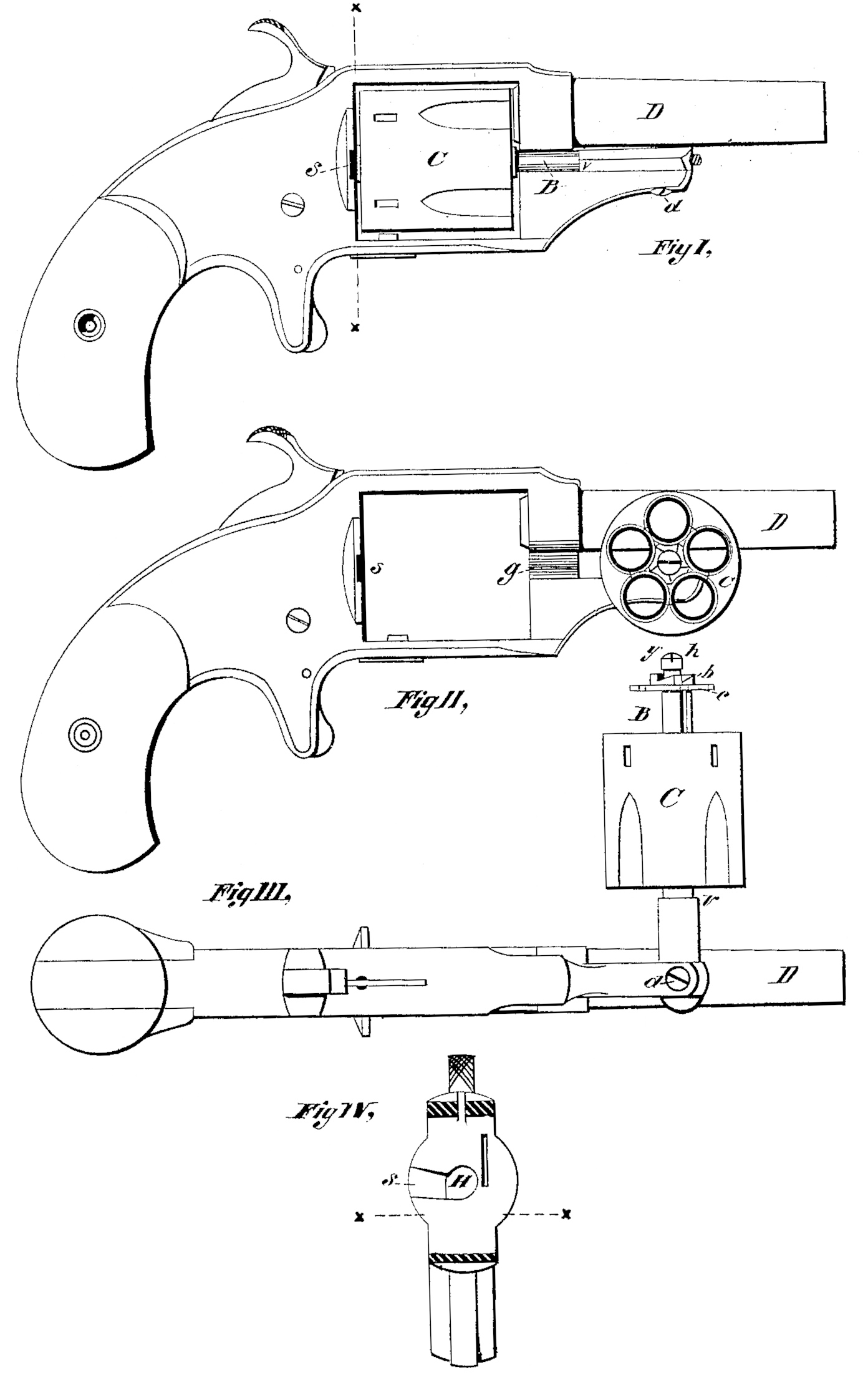

Figure I is a side elevation of a revolver embodying my present improvements; Fig. II, a similar view, the cylinder being swung out from the frame with the cylinder-pin to illustrate the relative position of the parts in extracting and loading. Fig. III is a side elevation of the cylinder in the position shown in Fig. II; and Fig. IV is a section on x x, Fig. I, showing the socket in the frame for receiving the free end of the cylinder-pin.

The cylinder-pin B has collared upon its inner and free end between a shoulder upon it and the flange of the screw h, the ratchet b and simultaneous extractor c, made in one piece, and together splined to the cylinder C, so that through the movement of the dog the cylinder will be rotated, while the ratchet and extractor will keep their proper position relative to the cylinder when the latter is receded to leave the shells upon the so-called extractor. The cylinder-pin B has its outer end hinged at d, between an extension of the frame and the barrel D, while a recess, 11, in the frame, and immediately beneath the barrel D, permits the pin B to lie in the same plane with the axis of the barrel.

In the wall of the frame, through which works the dog, is the socket H, as shown in Fig. IV. The socket H receives the extreme end of the cylinder-pin y, and is centered with it when in its normal position parallel to the axis of barrel. Access by the end y of the pin B is had to the socket H through the groove s in the same wall of the frame, and as this groove, deep enough to receive the end y, is coincident with the arc described by the end y, upon its hinge at d, it nearly disappears at the outer edge of the wall of the frame. The upper bearing-surface of groove s enters the socket at a point below the top of the socket, so that the cylinder-pin B, pushed into the groove s, is deflected from its normal center until received within the socket H, when the spring in the pin B asserts itself to recover its proper center against the top surface of the socket.

In operation, the thumbs are used upon the cylinder to press out the end y from the socket H to release the cylinder and enable it, with the cylinder-pin, to be swung out. When the cylinder is thus clear from the frame it is grasped as a convenient, handle and receded upon the pin to leave the empty shells upon the extractor, the cylinder being with equal facility reloaded and pushed back into place ready for firing.

The hinge-screw at d is made a set-screw, and a slight interval between the barrel D and the pin B intermediate to the extreme outer end of the pin and the upper bearing-surface of the socket enables the spring of the pin B to be measurably increased at will.

For the purpose of affording a broader lateral bearing-surface, a better hinge, and a stop for the cylinder by the shoulder v, the stock of the pin B is increased, as shown at the hinge end.

As the tendency in firing or at other times of the cylinder to swing out from its frame is slight, it is evident that, without any departure from the principle of this invention; the spring in the cylinder-pin can be dispensed with, and a spring-socket substituted as a fastening within the frame for the free end of the cylinder-pin, though for simplicity and strength the method illustrated in the drawings is preferred.

The hinge d may be placed at any desired point beneath the barrel, even at the extreme end, if desired.

In a pistol of this construction the number of parts is greatly reduced, hinges and spring-catches in the barrel and frame are dispensed with, together with all apparatus for operating an ejector, as the cylinder itself is detached from the empty shells without being removed from the pistol.

It is obvious that, were no extractor made part of the pistol-cylinder, when the cylinder was swung out the empty shells could be pushed out one at a time, and the cylinder reloaded, easier than these operations could be performed in the case of a pistol in which it was necessary to withdraw the cylinder-pin entirely.

Now, having described my invention, what I claim is—

1. In a revolving pistol, a spring cylinder-pin hinged at one end below the barrel, and having its other centered and held within the frame by force of the spring to permit the cylinder to be manually released and swung out upon the pin clear of the frame, and returned again to be held in the firing position, substantially as shown.

2. In a revolving pistol, the combination of cylinder, with spring cylinder-pin hinged at one end below the barrel, and having its other received into a socket in the frame, whereby by manually overcoming the resistance of the spring-pin, the cylinder can be secured in the frame for firing, or swung out clear of it to facilitate extraction or loading, as set forth.

3. In combination with the cylinder-pin, constructed to swing out laterally from the frame upon one end hinged beneath the barrel, and have the extractor collared upon its free end, the receding cylinder, whereby, when swung clear of the frame, the cylinder may be moved upon the pin away from the extractor to leave the shells thereupon, substantially as shown.

4. In combination with the spring-pin B and socket H, the set-screw d, for the purpose described.

ANDREW HYDE.

Witnesses:

C. L. Shattuck,

J. E. Porter.