US 228009

UNITED STATES PATENT OFFICE.

DANIEL B. WESSON, OF SPRINGFIELD, MASSACHUSETTS.

REVOLVING FIRE-ARM.

SPECIFICATION forming part of Letters Patent No. 228,009, dated May 25, 1880. Application filed April 9, 1880. (No model.)

To all whom it may concern:

Be it known that I, DANIEL B. WESSON, of Springfield, in the State of Massachusetts, have invented a new and useful Improvement in Revolving Fire-Arms, of which the following is a full, clear, and exact description.

My invention relates to the cylinder of a revolving fire-arm; and the object of the invention is to prevent the cylinder from being scratched by the stop in revolving it and to reduce the friction caused by the pressure of the stop against the cylinder and the consequent wear of the revolving mechanism.

To this end my invention consists of a groove made in the exterior of the cylinder, between the notches or indents with which the cylinder-stop engages to hold the cylinder in place, as will be more fully hereinafter described.

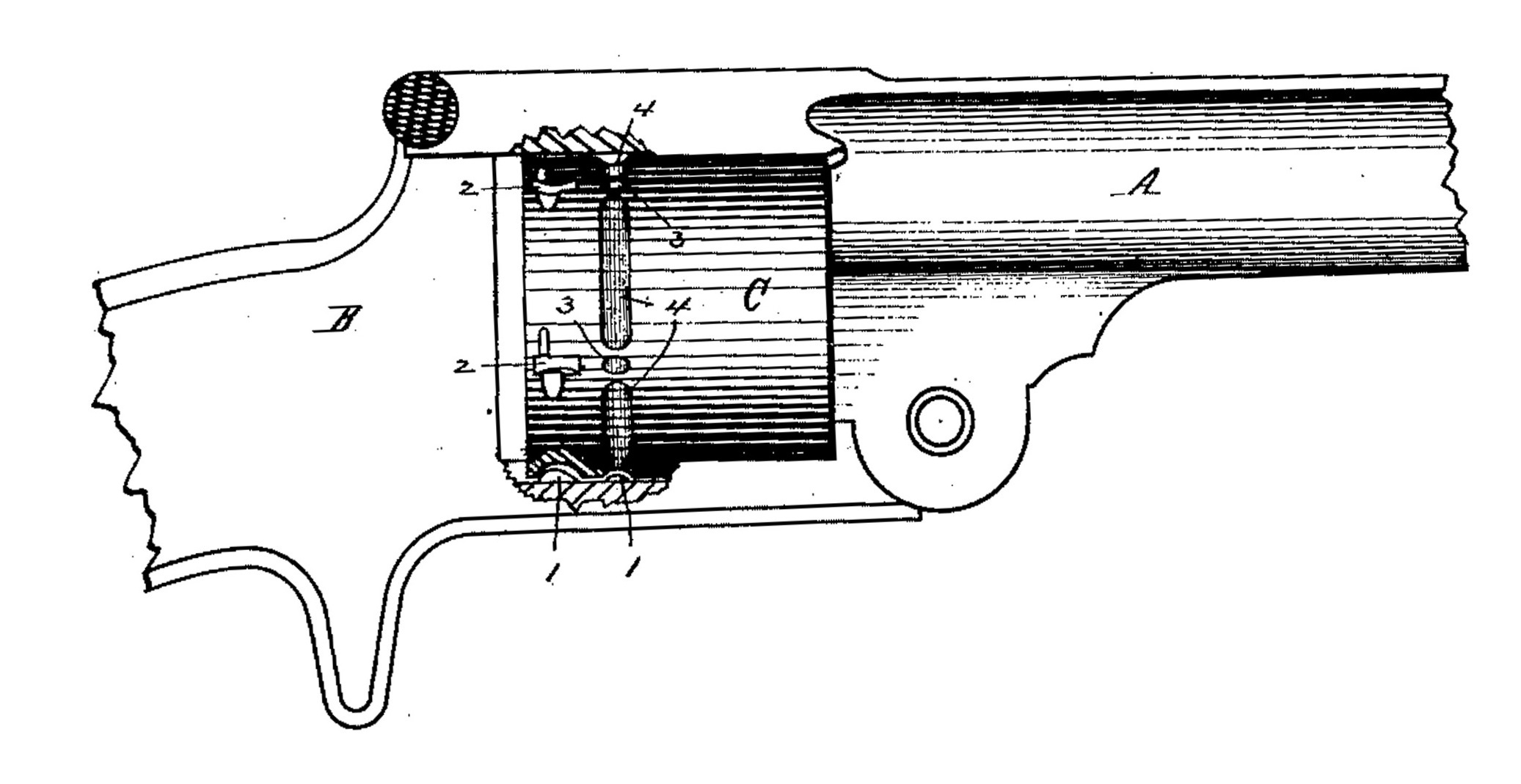

The figure is a side view of a portion of a revolving fire-arm with a part of the frame broken away to more clearly show my invention as applied to the cylinder.

In the drawing, A represents the barrel, B the frame, and C the cylinder, of a revolving fire-arm having, in this case, a double cylinder-stop, or a stop having two protuberances, 1, projecting upward so as to engage with two corresponding series of indents, 2 and 3, made in the exterior of the cylinder, at the proper distances apart, to hold the cylinder in position while being discharged. From a point near one of the indents 3, I make a groove, 4, sufficiently deep to receive the end of the cylinder-stop and extending to a point quite near to the next indent 3 in the same series, and I make these grooves all around the cylinder between the indents in the series.

When the cylinder is in a position to be discharged the cylinder-stop spring presses the protuberance 1 of the stop up into the indent 3, and the cylinder is thereby held firmly in that position; and when the cylinder is rotated the protuberance, after leaving the indent, is pressed up into the groove 4 until the next indent in the series is brought opposite the stop with which it engages, and so on all around the cylinder. As the cylinder-stop is thus allowed more upward play when not required for use in, holding the cylinder and while the cylinder is rotating, it is evident that the stop does not press against the cylinder with so great force, and consequently there is much less friction than when no groove is made in the cylinder, and the cylinder rotates easier.

In the construction of this class of fire-arms the cylinder is left in a soft condition, (not hardened,) and when no groove is provided the pressure of the stop against the cylinder is sufficient to soon wear a scratch-mark entirely around the cylinder, and the latter being soft, the friction is greater than if it were hardened, and this friction is, of course, objectionable, and soon causes no inconsiderable wear on those parts of the mechanism which actuate the cylinder. My invention obviates these objections, while it does not injure the appearance of the arm in the least, on the contrary, rendering it rather more ornamental than otherwise.

It is of course evident that this groove may be used upon a cylinder-revolver in which a cylinder-stop is used having only one protuberance projecting upward and one corresponding series of indents with equal advantage; and in revolving fire-arms in which a cylinder stop having two protuberances projecting upward is used the groove, may be made between the indents of both series corresponding to both protuberances.

Having thus described my invention, what I claim as new is–

In a revolving fire-arm, the combination of the cylinder-stop with the cylinder provided with stop notches or indents to receive the stop, and a groove, 4, made between each two adjacent said notches or indents, substantially as and for the purpose herein set forth.

DANIEL B. WESSON.

Witnesses:

T. A. CURTIS,

F. E. CURTIS.