USA 14488

UNITED STATES PATENT OFFICE.

G. A. BLITTKOWSKI AND F. W. HOFFMANN, OF NEW YORK, N.Y.

IMPROVEMENT IN NEEDLE-GUNS

Specification forming part of Letters Patent No. 14,488, dated March 25, 1856.

To all whom it may concern:

Beit known that we, Gustav Adolph Blittkowski and Frederick William Hoffmann, late of Germany, but now of the city, county, and State of New York, have invented certain new and useful Improvements in Revolving Needle-Guns; and we do hereby declare that the following is a full, clear, and exact description of the same, reference being made to the annexed drawings, making a part of this specification, in which—

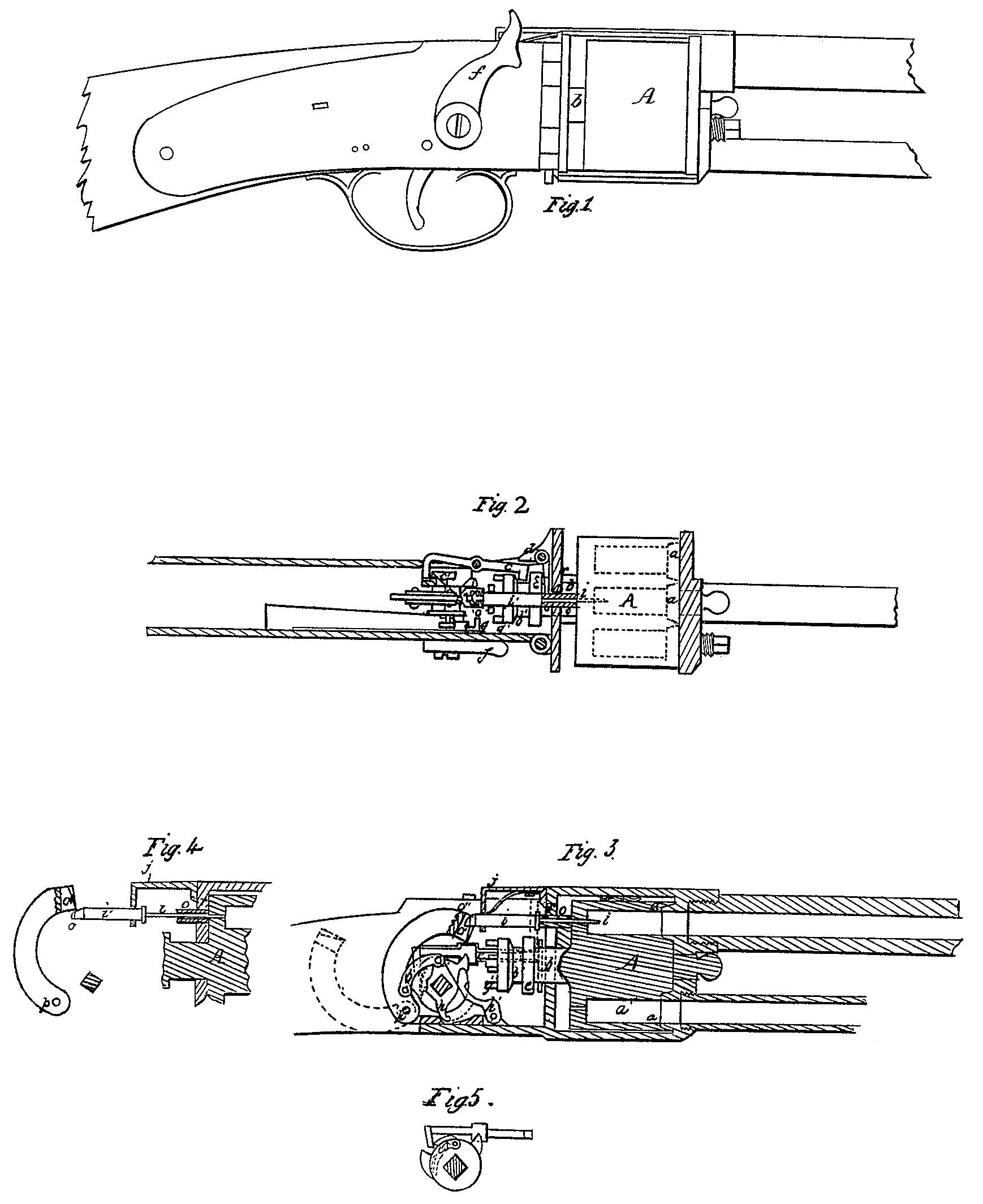

Figure I is a side view or elevation. Fig. II is a top view, partly in section. Figs. III, IV, and V are of parts in detail; and similar letters indicate similar parts throughout.

Our invention is for certain improvements in those revolving fire-arms in which the discharge is effected by the needle system. The breech revolves upon an axis which turns the same, and so arranged that said breech has two motions— viz., one revolving, as usual, and one vibratory in the direction of the axis. The charge-chambers are beveled at their mouths, forming a socket, so as to receive a beveled rim projecting from the end of the barrel, thus forming a tight joint. Before the breech can be rotated it must be withdrawn in order that the socket may clear the rim. The breech is shown at A and the form of the socket at a. The axis b projects through a division-plate, which forms one of its bearings, and terminates within the lock, where the motions necessary for the operations of the breech are imparted. These, as before mentioned, are in two directions. The first to be performed is the one by which the breech is to be drawn back in a line parallel with its axis, in order that the socket may be cleared from the projections. This is effected by the end of the locking-lever c, Fig. II, acting upon the end of a right-angled lever, d, the opposite end of which is forked and made to grasp the shaft behind the boss e of the grooved head, as shown. The opposite end of the lever c is bent, and terminates in a foot which engages in a cam, c’, upon the tumbler-shaft. Thus in the act of cocking the crooked end of c glides along the angular grooved cam c’. The opposite end is thus pressed against d, whereby the forked end of the latter lever is made to pull back the shaft b, and with it the breech-chamber.

At b’ is the locking-groove, into which one end of the lever c falls. This end must be removed before the breech can be drawn backward. There is therefore enough play between c and d for the point of the former to get out of said groove before the forked end of d begins to act against e.

The cocking is effected by pulling upon the handle f, Figs. I and II, which turns the tumbler-shaft on which are placed the several pieces for effecting the revolving and withdrawal of the breech-changer. As this is pulled over the first motion is to draw the latter back through the action of the lever c. At the moment this has been accomplished a foot, g, takes under one of the teeth g’, and as the motion of f is continued turns the breech one chamber forward. This done the reverse motion must be given along the axis to the former position, whereby the socket c is set to a tight joint. At h, Fig. III, is another foot upon the tumbler-shaft, which now comes into play by striking against a lever, h’, situated as shown in Fig. III, whereby its upper end is made to push against the axis b and thrust back the breech-chamber to its former position.

The principal part of the improvement is, first, the manner of operating the needle, whereby the latter, after having been driven into the cartridge in the act of firing, is withdrawn by a positive power produced by a peculiar method of locking it to the hammer-head at the moment when that gives the blow, so that the cocking shall cause the needle to be pulled back; and, secondly, in the arrangement of a movable guide for steadying the needle and at the same time make a tight joint around the touch-hole in the breech.

At i is the needle, affixed to a strong stock, i’, one end of which is supported by a bracket, j, while the other is held by the needle in its guide-tube, (shown at 0 as in the several figures.)

In the end of the hammer-head o” there is a clutch, the inside faces of which are so beveled or slanted that in the act of giving the blow the lower edges will pass over the head of the knob and embrace its shank, as shown at the detached view, Fig. IV, the blow which drives the needle forward being given upon the head by the end of the hammer. Thus at the end of the blow the knob is still held in the clutch. Therefore, in the act of cocking, as the hammer is drawn back the needle is pulled back also by the embrace of the clutch, which does not get clear until the needle has been withdrawn the proper distance. The arc described by the former finally separates the two by its rising above. The hammer is not fastened to the tumbler-shaft, but plays upon a separate center, as seen at p, and is made to move by a link or stirrup, p’, coupling it with an arm rising from the tumbler-shaft, as shown.

The needle-guide, which is also a stop to cover the touch-hole in the breech-chamber, consists of a tube, o, which has play both on the needle and also in a bearing in the plate r. This play of the tube is to allow for the motion of the breech when the latter is drawn back preparatory to turning, as exemplified in Fig. IV. When the hammer-head o” therefore strikes the stock i’ the needle passes through the tube until the shoulder at the stock strikes it, when the latter is also carried along until its opposite end strikes the breech-chamber, and this closes around the touch hole, the shoulder forming a stopper for one end and the back end of the breech the other.

In operation the cartridges, which are to be prepared as usual for needle-guns, are placed in the chamber a? either singly or by means of a magazine containing a number. The cocking-lever f is then pulled back, so that when it arrives at full-cock all the motions for withdrawing the breech, revolving it, and returning it to its proper position for firing have been gone through. The first motion brings the cam c’ into play and starts the levers c and d, by which the breech is withdrawn. At this moment the foot g has arrived at one of the pins g’, and the breech is rotated to the proper distance. The foot h has now pushed the lever h’ against the end of the axis, and the continued backward motion of the cock throws back the breech to its proper position. The needle now stands withdrawn and in position to be propelled forward by the blow of the hammer. The hammer, in its forward motion, arrives at the end of the needle-stock in such position that the knob shall enter the clutch from the under side, as it is represented in the act of doing in Fig. IV, the blow being then given to drive it forward with the cartridge, as before mentioned, whereby the cap within will be exploded in the usual manner.

We make no claim herein to the method of withdrawing and rotating the cylinder, inasmuch as that is embraced substantially in another application submitted by us; but

We claim—

1. The method of withdrawing the needle by a positive force applied thereto by means of the knob upon the end of the needle-stock, in combination with the claw upon the end of the hammer, so arranged that, becoming engaged at the moment of giving the blow, it shall cause the withdrawal of the needle in the operation of cocking, as described.

2. The guide-tube, for the double purpose of guiding the needle and of acting as a stop around the touch-hole, as described.

GUSTAY AD. BLITTKOWSKI.

FREDERICK WILLIAM HOFFMANN.

Witnesses:

J. P. PIRSSON,

S. H. MAYNARD.