US 39645

UNITED STATES PATENT OFFICE.

HENRY GROSS, OF TIFFIN, OHIO.

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 39,645, dated August 25, 1863.

To all whom it may concern: –

Be it known that I, HENRY GROSS, of Tiffin, in the county of Seneca and State of Ohio, have invented certain new and useful Im. provements in Revolvers; and I do hereby declare that the following is a full, clear, and exact description of the same, reference being had to the accompanying drawings, making a part of this specification, in which–

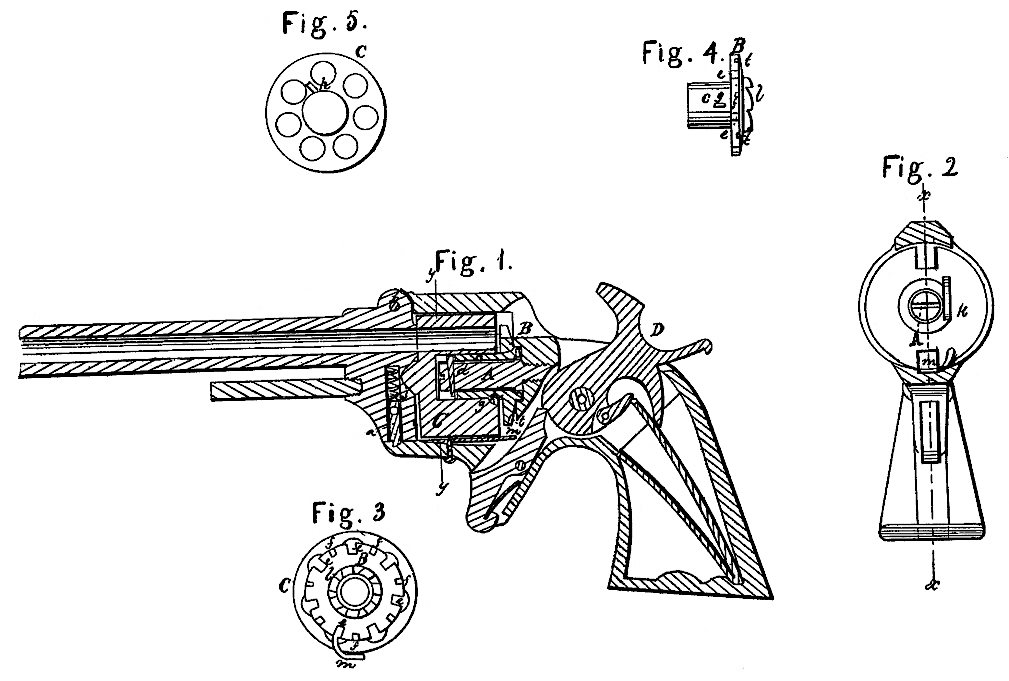

Figure 1 is a longitudinal vertical section in the line x x of Fig. 2; Fig. 2, a transverse section through the line y y of Fig. 1 with the cylinder and recoil-plate removed; Fig. 3, a rear view of the cylinder and recoil-plate; Fig. 4, a side view of the recoil-plate, and Fig. 5 a rear view of the cylinder.

The nature of my invention consists in combining a cylinder with a tubular recoil-plate, which is made to pass into but not entirely through said cylinder, one end of which is Solid or closed in front or at the end of said recoil plate.

To enable others skilled in the art to make and use my invention, I will proceed to describe its construction and operation.

My revolver is of the ordinary exterior form, the cylinder being released to be charged or cleaned by raising the catch a and elevating the barrel on its hinge b. A horizontal shaft, A, is screwed into the metallic part of the frame of the arm, upon which is placed the tubular part c of the recoil-plate B, where it is held by the pin d. This recoil-plate has formed in its periphery a number of slots, e, equal to that of, and when the cylinder is in position coincident with, the chambers of the said cylinder. Radial grooves f are also formed on the rear face of the said recoil-plate, intermediate between the slots e. The tubular part c of the recoil-plate B has a feather, g, on its exterior surface, which is received within the kerf h, cut in the axial bore of the cylinder C. This feather so connects the cylinder and recoil-plate that in use they operate together, while they may readily be detached and cleaned or the cylinder reloaded. It will be perceived that the axial bore does not extend quite through the cylinder, but that the said cylinder is provided on its forward end with an axial pivot, i, which is stepped at j.

The operation of my revolver is as follows:

The tubular recoil-plate B being pinned on its shaft A and the cylinder C placed thereon, the barrel is brought down and retained by the catch a. In this position the pivot i is in its step j, and the cylinder is pressed slightly rearwardly, confining the flanges of the metallic cartridges between the rear end of the cylinder and the recoil-plate B, thus avoiding undue friction between the rear end of the barrel and the front end of the cylinder.

The lock I have adopted is not unlike others heretofore used. The pawl k is connected with the heel of the hammer D, so that when the said hammer is withdrawn it has a forward motion and engages with the ratchet teeth l, formed around the rear end of axial bore of the recoil-plate, and gives the combined tubular recoil-plate and cylinder a partial revolution, sufficient to bring one of the chambers of the cylinder in line with the barrel, where it is stopped and held by the spring detent m, arranged beneath the cylinder, engaging with a corresponding slot, e. These slots e being arranged coincidentally with the chambers of the cylinder, and the recoil-plate B being of such diameter as nearly to cover their rear ends, the hammer can only reach a cartridge through a slot, thus preventing an accidental discharge unless the load passes through the barrel, while the object of the grooves f is to receive the hammer and lock the cylinder, thus preventing any accidental discharge even through the barrel.

The chief advantages gained by the use of my tubular recoil plate are, first, that it revolves with the cylinder, and therefore the recoil or expansion of the cartridge-case cannot impede its rotation, while in most other revolvers which use the flanged metallic cartridge-case the recoil or expansion is against an immovable breech, and it is difficult to rotate the cylinder without first removing the cartridge cases; second, that the tubular part thereof, extending within the axial bore of the cylinder, gives the recoil-plate additional strength, and it has at all times an equal bearing, and this equality is possessed as well after a discharge as before, and when the copper or brass cartridge-case recoils with its greatest force; that the cylinder C, being bored only a part of the way through, protects the recoil-plate B from the gas which escapes upon the discharge of the revolver, and which otherwise would pass in at the end of the recoil-plate between it and the cylinder, and thus render it difficult to remove the cylinder from the recoil-plate for the purpose of reloading.

Having thus described my invention and pointed out its mode of operation, what I claim and desire to secure by Letters Patent of the United States, is–

The cylinder C, in combination with tubular recoil-plate B, when the said cylinder is so constructed as to shield the end of the recoil-plate, substantially as and for the purposes specified.

HENRY GROSS.

Witnesses:

JESS H. LEIDY,

J.H. NIGHSWANDER.