US 43606

UNITED STATES PATENT OFFICE.

JACOB RUPERTUS, OF PHILADELPHIA, PENNSYLVANIA.

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 43,606, dated July 19, 1864.

To all whom it may concern:

Be it known that I, Jacob Rupertus, of Philadelphia, Pennsylvania, have invented an Improvement in Revolving Fire-Arms; and I do hereby declare the following to be a full, clear, and exact description of the same, reference being had to the accompanying drawings, and to the letters of reference marked thereon.

My invention consists of certain improvements, fully described hereinafter, in fire-arms having barrels containing a number of bores.

In order to enable others skilled in the art to make and use my invention, I will now proceed to describe its construction and operation.

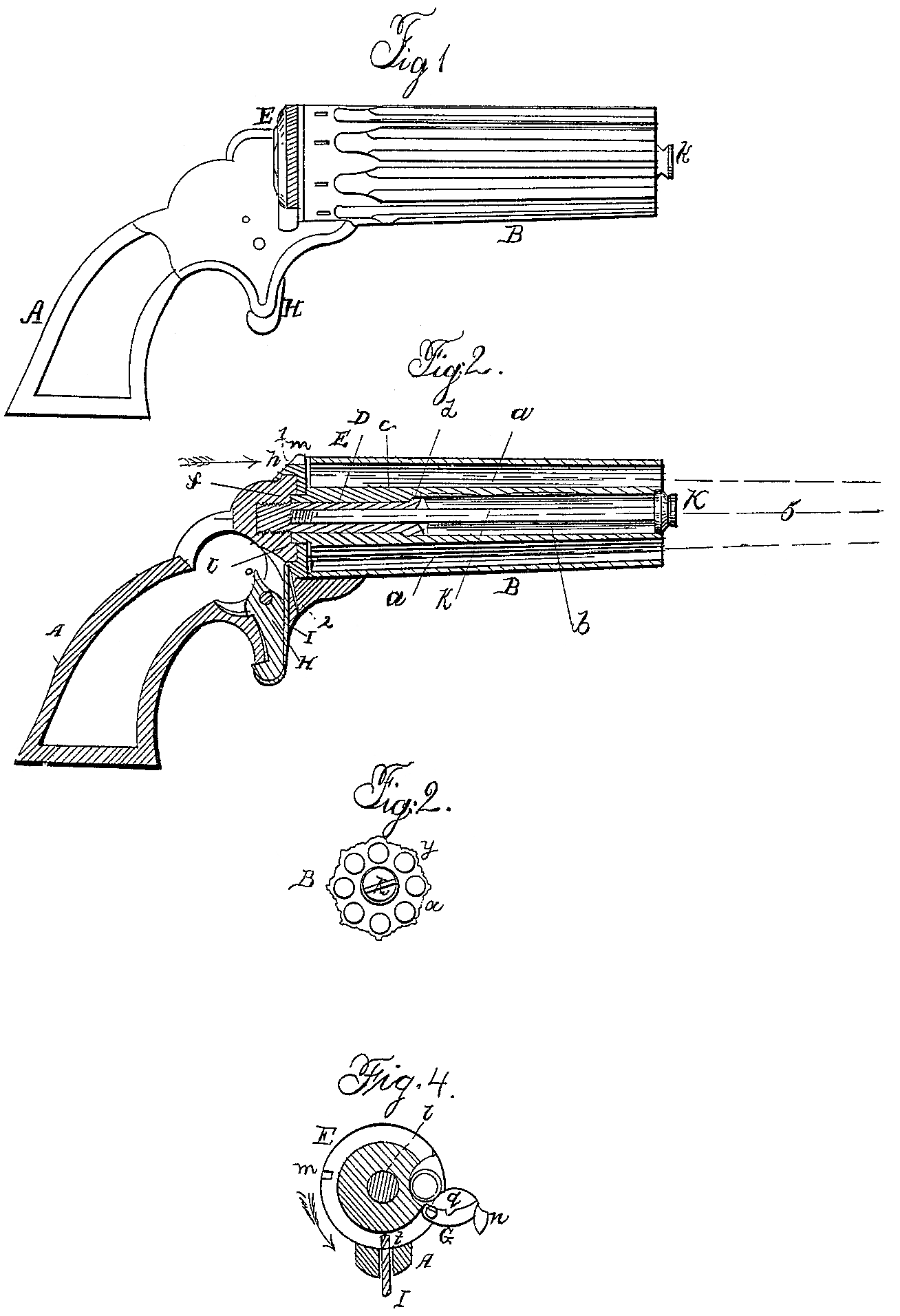

On reference to the accompanying drawings, which form a part of this specification, Figure 1 is a side view of my improved revolving fire-arm; Fig. 2, a longitudinal section; Fig. 3, an end view of the barrel; Fig. 4, a transverse. section on the line 12, Fig. 2, looking in the direction of the arrow.

Similar letters refer to similar parts through out the several views.

A represents the stock, and B the barrel, of my improved fire-arm, the barrel having in the present instance eight bores, a, arranged in a circle, the center of which coincides with the axis 5, round which the barrel revolves, and with the center of the tubular chamber b. The breech-pin D, on which the barrel turns, is inserted into this chamber, which is reduced in diameter near the rear end of the barrel, so as to be adapted to the said breech-pin, the head d of which bears against a shoulder, e, the end of the pin being secured into the stock A, and a tubular projection, f, at the rear end of the barrel being arranged to fit into and turn in the said stock.

Between the stock and the rear end of the barrel intervenes a circular and movable breech-piece, E, a flange, h, on which overlaps the edge of a circular plate, i, formed on the stock, on which plate, as well as on the tubular projection f of the barrel, the breech-piece is arranged to turn to a limited extent.

It should be understood that the bores of the barrel are arranged for the reception (at the rear) of the ordinary metallic cartridges, the charged flanges of which intervene between the rear of the barrel and the breech-piece, a notch, m, being cut at one point in the latter to permit the end of the hammer to strike the flange of that cartridge which is contained in the uppermost bore of the barrel.

The breech-piece E and the circular plate i of the stock are cut away at one point, as seen in Fig. 4, so as to afford room for the introduction of the cartridges into the bores of the barrel.

To the breech-piece, near the point thus cut away, is hinged a door, G, which, when closed against the said breech-piece, covers the part cut away, but which, when open, as seen in Fig. 4, permits the introduction of the metallic cartridges into the bores of the barrel. This door is provided with a lip or projection, n, and with a notch, q, which, together with a notch, t, at the rear of the breech-piece, will be alluded to hereinafter.

The rear end of the tubular projection f is provided with angular teeth similar to those on the cylinders of ordinary revolving fire-arms, the teeth being acted on by a dog, which is caused to turn the barrel during the cocking of the hammer.

As the hammer, dog, and lock are similar to those of other revolving fire-arms, it has not been deemed necessary to illustrate them in the drawings.

To the trigger H, which is also of the usual construction, is secured the spring I, the upper and rounded end of which is arranged to engage into the notch t of the breech-piece and into the notch q of the door.

It will be observed that the barrel, although containing a large number of bores, is rendered very light by its peculiar construction.

The bores of the barrel, instead of being parallel with the axial line 5, round which the barrel revolves, as in other fire-arms of this class, all converge to one point in this line. In other words, the center of each bore at the front end of the barrel is nearer to the axial line 5 than at the rear end of the barrel. By this arrangement and by removing the metal so as to form the central tubular chamber, b, I have been enabled to form a very light barrel, and yet one of appropriate strength. The barrel is rendered still lighter by removing from its outside, at pints x, Fig. 3, between the bores, as much metal as possible, taking care to leave at a point parallel with the center of each bore a longitudinal ridge, y, by means of which the proper sighting of the fire-arm is effected.

A rod, K, passes through the center of the tubular chamber b, the head k of the rod fitting snugly but freely into the front end of the chamber, the end of the rod being secured into an orifice in the breech-pin D, so that it can be readily removed and used as an instrument for forcing the spent cartridges from the rear of the chambers.

Prior to loading the fire-arm the breech-piece E is removed to the position shown in Fig. 4, when the end of the spring I engages into the notch t. When the breech-piece has been moved to this position, and is there lightly held by the said spring, the operator can depress the door G and introduce a cartridge into one of the bores of the barrel, the latter being turned until a cartridge can be inserted into another bore, and so on until every bore is charged, after which the door G is closed and the breech-piece is turned back in a contrary direction to that pointed out by the arrow, Fig. 4, and until the lip in of the door comes in contact with the stock A and the end of the spring I enters the notch q, when the fire-arm is in a condition to be discharged.

In loading the fire-arm no accidental discharge of the cartridges can take place, for when the loading is being effected the notch m in the breech-piece, through which the hammer must pass, is turned away from the course of the hammer, so that the latter, should it accidentally fall, cannot reach the charged flanges of the cartridges. The same safety can be insured, when the loaded fire-arm has to be carried in the pocket, by turning the breech-piece to the position shown in Fig. 4.

It will be evident that the peculiar method of constructing the barrel B is applicable to the cylinders of ordinary revolving fire-arms.

I claim as my invention and desire to secure by Letters Patent—

1. A breech-piece, E, intervening between the rear end of the barrel and the stock, when the said breech-piece is arranged to turn, substantially as set forth.

2. The notch m, formed at or near the edge of the said breech-piece, as set forth, for the purpose specified.

3. The combination of the said movable breech-piece with the door G or its equivalent.

4. The said movable breech-piece, with its notches t and q, in combination with the spring I.

In testimony whereof I have signed my name to this specification in presence of two subscribing witnesses.

JACOB RUPERTUS.

Witnesses:

Charles E. Foster,

Charles Howson.