Britain 779

A.D 1869, 13th March. № 7793

Repeating Fire-arms.

LETTERS PATENT to John Thomas, of Birmingham, in the County of Warwick, Gun and Pistol Manufacturer, for the Invention of “Improvements in Repeating Fire-arms.”

Sealed the 3rd August 1869, and dated the 13th March 1869.

PROVISIONAL SPECIFICATION left by the said John Thomas at the Office of the Commissioners of Patents, with his Petition, on the 13th March 1869.

I, John Thomas, of Birmingham, in the County of Warwick, Gun and Pistol Manufacturer, do hereby declare the nature of the said

Invention for “Improvements in Repeating Fire-arms,” to be as follows:—

My Invention consists in constructing and arranging in the manner herein-after described the parts of repeating Fire-arms for the purpose of extracting simultaneously the whole of the cases of the exploded cartridges from the chambers of the revolving barrels or cylinders of the said fire-arms, and also for effectually supporting the snivel revolving barrels or cylinders during the discharge of the fire-arms.

I will describe my Invention as applied to a repeating pistol. I make the rectangular opening in the solid body or frame of the pistol in which the revolving cylinder works of such a length that the said cylinder is capable of sliding for a short distance therein, that is to say, I make the said opening in the body or frame a little longer than the combined length of the revolving cylinder and the cartridges to be used in the chambers of the said cylinder. The said revolving cylinder is moved to and fro in the said body or frame in the manner herein-after explained. On the axis of the revolving cylinder is a tube having at its rear end or that end nearest the back of the body an extractor. The said extractor consists of a disc or plate having a series of curved notches ma&le in it equal to the number of the chambers in the revolving cylinder. The said extractor with its tube is capable of turning on the axis of the revolving cylinder, but is incapable of sliding on the snivel axis. Upon the tube of the extractor the revolving cylinder works, the said tube and cylinder being connected together by a pin or rod on the extractor entering a hole in the said cylinder. At the back of the extractor is a ratchet acted upon by an arm of the lock for rotating the revolving cylinder. In order to extract the cases of the exploded cartridges from the chambers of the revolving cylinder it is necessary tint the said cylinder should slide from the back of the body to the opposite end of the opening in the said body. This I effect and also support the revolving cylinder during discharge in the following manner:— Instead of fixing the long barrel of the pistol to the front and upper side of the body or frame as usual, I make the said barrel capable of a partial relation in the said frame or body. The rear or inner end of the said barrel passes through the end of the body or frame into the opening in the said body or frame in which the revolving cylinder works and slides, the said inner end of the barrel bearing against the cylinder. A lug on the barrel outside the frame or body engages with a recess in the said frame or body, and locks the said barrel in its place. On the inner end of the barrel is an annular depression or groove in which a ring or collar on the end of the revolving cylinder engages. When it is unshed to extract the exploded cartridge cases from the chambers of the revolving cylinder the barrel is partly rotated by a handle fixed on it. The lug on the barrel is thereby removed from its slot in the frame or body and the barrel released; By sliding the said barrel forward the revolving cylinder is brought to the front end of the opening in the body, and the whole of the cases of the exploded cartridges are extracted by the fixed extractor near the back of the body; The revolving cylinder is then returned to its place near the back of the body, and fixed there by the engaging of the lug on the barrel with the recess in the body or frame. When the revolving cylinder is in the last-described position the cartridges are introduced into the chambers of the said cylinder from the breech end in the ordinary way.

I do not limit myself to the arrangement described for locking or fastening the barrel to the frame or body, as various other ways may be adopted for effecting the same object. For example, screw threads may bc cut on one-half the barrel, which may by a semi-rotation be made to engage with similar half screw threads on the frame or body. The sliding motion of the barrel and chamber may be effected by a rack and pinion or other mechanical advancement which does not require a rotary motion in the barrel. The essence of my Invention consists in making the barrel capable of sliding in the frame and carrying the chamber with it in its sliding motion.

SPECIFICATION in pursuance of the conditions of the Letters Patent„ filed by the said John Thomas in the Great Seal Patent Office on the 11th September 1869.

TO ALL TO WHOM THESE PRESENTS SHALL COME, I, John Thomas, of Birmingham, in the County of Warwick, Gun and Pistol Manufacturer, send greeting.

WHEREAS Her most Excellent majesty Queen Victoria, by Her Letters Patent, bearing date the Thirteenth day of March, in the year of our Lord One thousand eight hundred and sixty-nine, in the thirty-second year of Her reign, did, for Herself, Her heirs and successors, give and grant unto me, the said John Thomas, Her special licence tint I, the said John Thomas, my executors, administrators, and assigns, or such others as I, the said John Thomas, my executors, administrators, and assigns, should at any time agree with, and no others, from time to time and at all times thereafter during the term therein expressed, should and lawfully might, make, use, exercise, and vend, within the United Kingdom of Great Britain and Ireland, the Channel Islands, and Isle of Man, an Invention for “Improvements in Repeating Fire-arms,” upon the condition (amongst others) that I, the said John Thomas, my executors or administrators, by an instrument in writing under my, or their, or one of their hands and seals, should particularly describe and ascertain the nature of the said Invention, and in what manner the same was to be performed, and cause the same to be filed in the Great Seal Patent Office within six calendar mouths next and immediately after the date of the said Letters Patent.

NOW KNOW YE, that I, the said John Thomas, do hereby declare the nature of the said Invention, and in what manner the same is to be, performed, to be particularly-described and ascertained in and by the following statement thereof, that is to say:—

My Invention consists in constructing and arranging in the manner herein-after described the parts of repeating fire-arms for the purpose of extracting simultaneously the whole of the cases of the exploded cartridges from the chambers of the revolving barrels or cylinders of the said fire-arms, and also for effectually supporting the said revolving barrels or cylinders dining the discharge of the fire-arms.

I will now describe my Invention as applied to a repeating pistol. I make the rectangular opening in the solid body or frame of the pistol in which the revolving cylinder works of such a length that the said cylinder is capable of sliding for a short distance therein, that is to say, I make the said opening in the body or frame a little longer than the combined length of the revolving cylinder and the cartridges to be used in the chambers of the said cylinder. The said revolving cylinder is moved to and fro in the said body or frame in the manner herein-after explained. On the axis of the revolving cylinder is a tube having at its rear end or that end nearest the back of the body an extractor. The said extractor consists of a disk or plate having a series of. curved notches made in it equal to the number of the chambers in the revolving cylinder. The said extractor with its tube is capable of turning on the axis of the revolving cylinder but is incapable of sliding on the said axis. Upon the tube of the extractor the revolving cylinder works, the said tube and cylinder being connected together by a key on the extractor entering a hole in the said cylinder. At the back of the extractor is a ratchet acted upon by an arm of the lock for rotating the revolving cylinder. In order to extinct the cases of the exploded cartridges from the chambers of the revolving cylinder it is necessary that the said cylinder should slide from the back of the body to the opposite end of the opening in the said body. This I effect and also support the revolving cylinder during discharge in the following manner:— Instead of fixing the long barrel of the pistol to the front and upper side of the body or frame as usual I make the said barrel capable of a partial rotation in the said body or frame. The rear or inner end of the said barrel passes through the cud of the body or frame into the opening in the said body in which the revolving cylinder works and slides, the said inner end of the barrel bearing against the cylinder. A lug on the barrel outside the frame or body engages with a recess in the said frame or body and locks the said barrel in its place. On the inner end of the barrel is an annular depression or groove in which a ring or collar on the end of the revolving cylinder engages. When it is wished to extract the cases of the exploded cartridges from the chambers of the revolving cylinder the barrel is partly rotated by a handle fixed on it. The lug on the barrel is thereby removed from its slot in the frame or body and the barrel released. By sliding the said barrel forward the revolving cylinder is brought to the front end of the opening in the body and the whole of the cases of the exploded cartridges are extracted by the fixed extractor near the back of the body. The revolving cylinder is then returned to its place near the back of the body and fixed there by the engaging of the lug on the barrel with the recess in the body. When the revolving cylinder is in the last-described position the cartridges are introduced into the chambers of the said cylinder from the breech end in the ordinary way.

I do not limit myself to the arrangement described for locking the barrel to the frame, as various other ways may be adopted and the barrel may be made to slide in the frame and carry with it the revolving cylinder in ways different from that described; and instead of extracting the exploded cases by the sliding of the revolving cylinder from the fixed extractor the reverse arrangement may be used, that is, the revolting cylinder may be fixed and the extractor be moved from it in the space in the opening in the body or frame.

Having explained the nature of my Invention I will proceed to describe with reference to the accompanying Drawings the manner in which the same is to be performed.

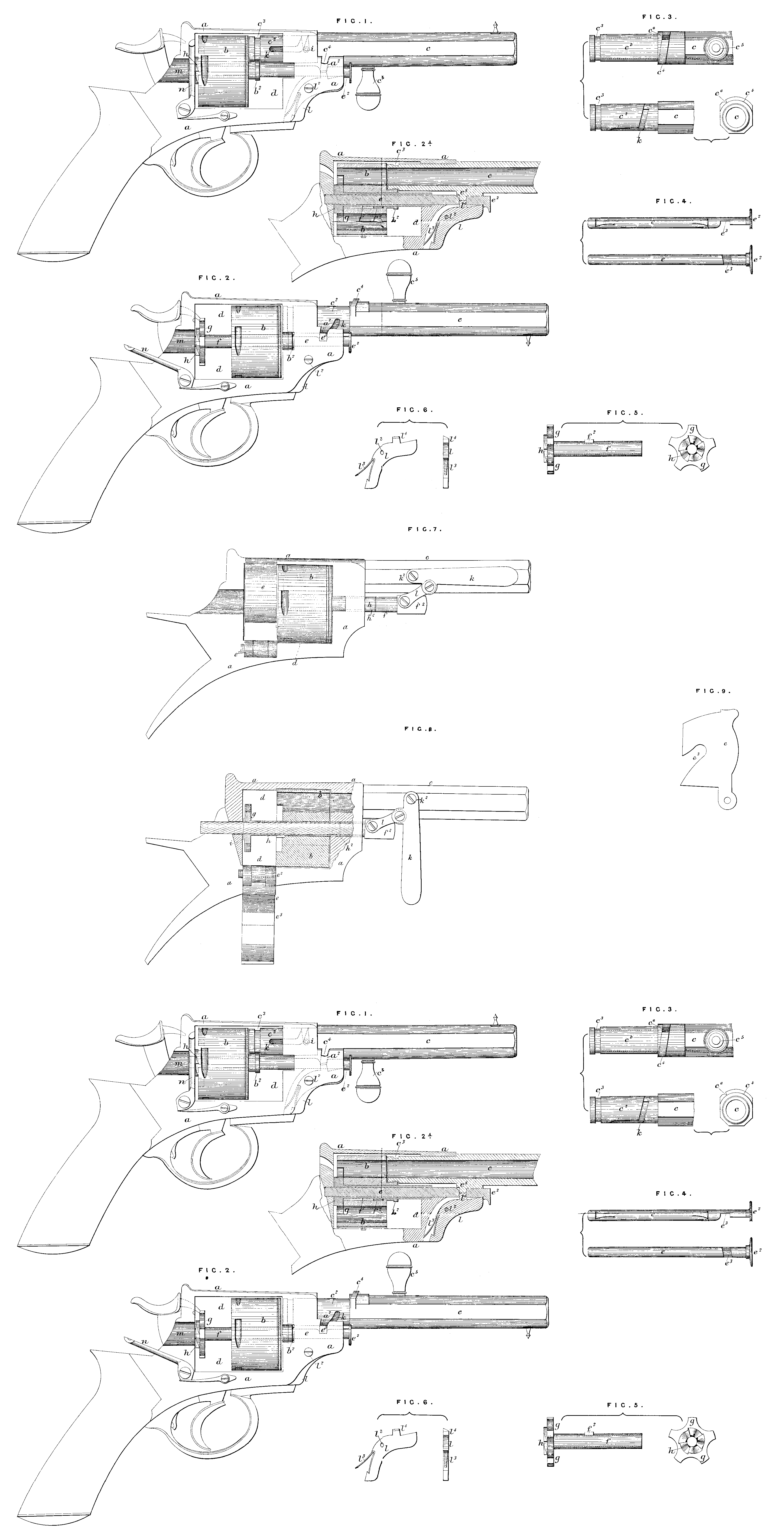

Figure 1 represents in side elevation a repeating pistol constructed according to my Invention, the parts of the said pistol being in position for discharge, and Figure 2 represents the same after the exploded or empty cartridge cases have been extracted from the chambers of the revolving cylinder of the’ pistol; Figure 2ᴬ represents a longitudinal section of the pistol; Figures 3, 4, 5, and 6 represent parts of the same as herein-after explained. The same letters of reference are used to indicate the same parts in Figures 1, 2, 2ᴬ, 3, 4, 5, and 6.

a, a, is the solid body or frame of the pistol, and b is the revolving cylinder working in the said solid body; c is the barrel of the pistol. The rectangular opening d in the solid body a is of such n length as to permit of the cylinder b sliding to and fro therein for the purpose of extracting the empty cartridge cases from the said cylinder, that is to say, the said opening d in the body or frame a is a little longer than the combined lengths of the cylinder b and the cartridge cases used in the chambers of the said cylinder. e is the axis of the revolving cylinder b passed through the solid body a from the front end to the back end thereof. The axis e is shown separately in Figure 4. On the said axis a

is a tube f having at its rear end and near the back of the body a an extractor g. The said extractor and tube f, g, are shown detached from the pistol in Figure 5. From an examination of Figure 5 it will be seen that the extractor g consists of a disk or plate having a series of curved notches in its periphery equal to the number of the chambers in the revolving cylinder b. When the cylinder b is in position for discharge the extractor g occupies a suitably shaped depression made in the rear face of the said cylinder and lies flush with the said face, as indicated in dotted lines in Figure 1. The extractor g and tube f are capable of turning on the axis e but are incapable of sliding on the said axis, the ends of the said tube f bearing respectively against the ends of the frame or body a. Upon the tube f of the extractor the revolving cylinder b works, the said cylinder being capable both of rotating with and sliding upon the said tube f. The cylinder b is connected with the tube f by means of n pin or key f² on the tube f (see Figure 5) engaging in a groove or key way in the said cylinder. By means of the key and keyway described the rotation communicated to the tube f is transmitted to the cylinder b while the said cylinder is permitted to slide upon the said is given to the cylinder b for the purpose of bringing each of its chambers in succession in a line with the barrel c by means of an arm of the lock constructed in the usual way propelling forward the ratchet h at the back of the extractor, the motion communicated to the ratchet being transmitted through the tube f to the cylinder b.

In order to extract the cases of the exploded cartridges from the chambers of the revolving cylinder b it is necessary that the said cylinder should slide from the back of the solid hotly or frame a to the opposite end or front of the opening d in the said body, that is, from The position represented in Figure 1 to that represented in Figure 2. The sliding of the cylinder b is effected and the said cylinder supported during discharge by the following construction and arrangement of parts:— The barrel c is made capable both of sliding and partially rotating in the body or frame a instead of being fixed to the front and upper side of the said body as is usual. The rear or inner end c² of the barrel c is made smaller than the other part and passes through the front end of the body a into the opening d in the said body, the said inner end of the barrel bearing against the cylinder b, but permitting the cylinder to rotate. The cylinder b is connected with the and c² of the barrel c by means of a ring or collar b² on the cylinder engaging with an annular groove or depression c³ in the end of the barrel c, as represented in the Drawing. Plans taken at opposite sides of the rear end c² of the barrel c and an end elevation are represented in Figure 3. On the under side of the barrel c is an inclined lug c’ (see Figure 3), which can by a partial rotation of the barrel be made to engage in a recess a² in the frame or body a. By means of this lug the barrel c is locked to the frame a and the cylinder is at the same tie supported for discharge. When it is wished to extract the exploded cartridge cases from the chambers of the revolving cylinder b the barrel c is brought by partially rotating it by the handle c⁵ from the position represented in Figure 1 to that represented in Figure 2. The lug c⁴ is thereby removed from the slot or recess a² in the body or frame a and the barrel c is released. By then sliding the barrel c forward the revolving cylinder b is moved on the tube f and brought from the position represented in Figure 1 to that represented in Figure 2. By the sliding of the cylinder b from the back of the body a to the front the roof the whole of the exploded cases of the cartridges are extracted from the chambers of the cylinder b by the fixed extractor g, the cases being retained as the cylinder slides forward by the engagement of their rims with the notches of the said extractor g. As soon as the cylinder b reaches the position represented in Figure 2 the extracted cases being no longer supported fall from the extractor, and the cylinder b is ready to be reloaded. To effect this the said cylinder is first moved back to the position represented in Figure 1 by sliding the barrel c by its handle c⁵. The snivel barrel is then partly rotated and its lug c⁴ made to engage with the recess a² in the body a. B means of the said lug the barrel c is securely fixed or locked to the body or frame, the wedging action of the lug causing the inner end c² of the said barrel to be held truly against the face of the cylinder so as to effectually support it during the discharge of the pistol. When in this position fresh cartridges may be introduced into the chambers of the cylinder through the ordinary opening or channel m at the back of the body, the rims of the cartridges placed in the chambers resting a against the extractor g. The opening m is closed after loading by the ordinary hinged covering plate n. The sliding and partial rotation of the barrel c in the body or frame a is limited and the said barrel guided by a pin i on the body engaging in a longitudinal and cross slot k in the said barrel. In order to prevent the accidental unlocking of the barrel c a safety catch or fastening l is situated at the front end of the frame or body a. The said fastening consists of a lever (shown separately in Figure 6) turning on the centre l² and pressed upwards by the spring l³. On the nearly horizontal arm of the lever is a tooth l⁴, which when the barrel is locked in its place enters a notch c⁵ in the lug c⁴, and thereby prevents the rotation of the said barrel. By pressing inwards the projecting lower arm of the lever or fastening l the tooth l⁴ is withdrawn from the notch c⁶, when the barrel c may be turned by its handle for unlocking it preparatory to the extraction of the empty cartridge cases, as herein-before described. When it is required to remove the cylinder b from the solid body or frame a for cleaning or for other purpose the barrel c is first unlocked, as represented in Figure 2. By then grasping he head e³ of the axis e the said axis may be withdrawn from the frame a, when the cylinder b, tube f, and extractor g maybe removed from the said frame by a lateral motion through the open side of the said frame. In order to ensure the axis e being fixed in its place preparatory to discharge its rear end is provided with a cross recess e² (see the separate views, Figure 4), into which recess the lug c⁴ on the barrel c passes when the latter is locked in its place. The position of the lug c⁴ with respect to the axis e is such that if by carelessness the said axis has not been fully pushed home the barrel b cannot be locked as the recess e³ in the said axis will not be brought opposite the said lug.

I do not limit myself to the arrangement described and represented for locking or fastening the barrel to the frame or body, as various other ways may be adopted for effecting the same object; for example, screw threads may be cut on one half the barrel, which may by a semi-rotation be made to engage with similar half screw threads on the frame or body. The sliding motion of the barrel and revolving cylinder may be effected by a rack and pinion or other mechanical arrangement which docs not require a rotary motion in the barrel; but these and other details of my Invention I do not think it necessary further to describe.

Figure 7 represents in side elevation a modification of the last-described pistol, the parts being in position for firing, and Figure 8 represents the same partly in longitudinal section, the parts being represented in the positions which they respectively occupy after the cases of the exploded cartridges have been extracted; figure 9 represents a part of the same. The same letters indicate the same parts in Figures 7, 8, and 9. In this arrangement of my Invention in place of making the revolving cylinder b slide in the long opening d in the body a to extract the cases I station the said revolving cylinder at the front of the said opening d and make it incapable of sliding, the extractor moving from the said cylinder to extract the cartridge cases. The cylinder b is secured at the front end of the opening d by making the body a at that part wider, in which part the cylinder rotates. The space in the body a between the back of the said body and the rear face of the cylinder b is sufficient to extract the cases of the cartridges from the chambers of the said cylinder. The barrel c is fixed to or made in one piece with the solid body a. The revolving cylinder b is supported in its place during discharge by menus of a solid block c hinged at e³ to the side of the solid body a. The said block o is capable of being turned into or out of the body a by turning on the joint c². When the block e is raised as illustrated in Figure 7 it enters the opening in the solid body and accurately fills up the space between the back of the body and the rear face of the cylinder b and supports the said cylinder firmly in the body during discharge. The block c is shown separately in Figure 9. In the said block e is a deep slot e³, into which when the block is raised the axis g of the revolving cylinder b enters. The block e may be fixed in its raised position by a spring snap fastening engaging with the top of the solid body a. The supporting block e is turned down, as illustrated in Figure 8, when it is wished to extract the cartridge cases. The space at the rear of the cylinder is thus clear for the operation of the sliding extractor g. The said extractor g is fixed on the tube h, the said tube h being connected with the cylinder b by a sliding key as usual. The extractor tube h is secured on the axis f by bearing at one end against the shoulder h² and at the other and against the cross pin i. The extractor tube h is by this arrangement capable of rotating on the axis f and of sliding with the said axis when the latter is moved backwards and forwards. The axis f is moved to and fro for operating the extractor g and returning it to its place in the cylinder b by means of the lever k jointed at k to the fixed barrel c. The said lever k is connected by a link l to the enlarged end f² of the axis f. By depressing the said lever k in the manner represented in Figure 8, after the block c has been turned out of the solid frame or body a, the axis f is pushed towards the back of the body a, the extractor tube h and extractor g being carried with it, as illustrated in Figure 8. The cases of the exploded cartridges are thus simultaneously extracted from the chambers of the revolving cylinder b. In order to reload the pistol the lever k is raised, as illustrated in Figure 7; the extractor g is thereby returned to its place in the rear of the cylinder b, and fresh cartridges may be introduced into the chambers of the said cylinder. After loading the pistol the block e is raised and turned1 into the solid body or frame a, as illustrated in Figure 7, when the pistol is ready for discharge. By a solid body or fame as employed in the arrangements described I wish it it to be understood that I mean any body or frame which is made in one piece or in two or more pieces fastened together so as to form a continuous body or frame, or body or frame the parts of which are not separated in extracting the cases of the exploded cartridges.

Figures 10, 11, 12, 13, 14, and 15 represent another mollification of the repeating pistol, Figures 1 and 2; Figure 10 representing a side elevation of the pistol in position for firing; Figure 11, a side elevation; Figure 12 a plan, and Figure 13 an end elevation of the same after the barrel and revolving cylinder have been moved from the back of the body to extract the cases of the exploded cartridges; Figure 14 is an end elevation of the pistol, Figure 1, taken at the rear thereof; Figure 15 represents the axis of the cylinder and extractor detached from the pistol. Instead of using, as previously described, a solid body or frame in this arrangement of my Invention, I make the body in two parts, and connect the moveable part of the barrel and lock, the said movable part, and barrel to the fixed part of the body by an arrangement of inclined or excentric lugs similar to that by which the barrel c, Figures 1 and 2, is locked to the solid body or frame. The same letters indicate the same parts in Figures 10, 11, 12, 13, l4 and l5.

a, is the fixed part of the body or frame, and b is the moveable part connected to or made in one piece with the barrel c; d is the revolving cylinder; e is the axis (shown separately in Figure 15), and f is the extractor, the tube f² of which is connected to the cylinder d and rotates on the axis e in the manner previously described with respect to Figures 1 and 2. The extractor f is incapable of sliding. The barrel c and moveable frame b are capable of rotating through a, quarter of d circle and of sliding upon the axis e. The frame b is connected to the axis e by the pin or stop g. The pin g works in a cross slot b in the axis e during the quarter rotation of the frame b, and works in the longitudinal slot h² in the said axis during its sliding motion. When the moveable part b of the body has been turned on the axis e so as to open the frame or body of the pistol, the said part b is situated horizontally, as illustrated in Figures 11, 12, and 13, but when the said body b is moved back a quarter rotation in order to close the body or frame, the said part b is situated vertically, as illustrated in Figures 10 and 14. The moveable part b of the body and the barrel c arc connected or locked to the fixed part a of the body at back an&1 front by means of the excentric or inclined lugs i, k, at back and front of the said part b. The lug k at the front of the part b takes into a, recess l in the fixed part a, and the lug i at the back of the part b passes behind the shoulder in m the fixed part a. The lugs i, k, are curved to a portion of a circle and take upon correspondingly shaped beds or seats at m, l. When the inclined lugs i, b, are engaged with the body a, the moveable part b of the body and the barrel c arc securely locked to the part a, and the revolving cylinder d is thus firmly supported in the frame during discharge. In addition to the lug k entering the recess l in the body a, the lower part of the moveable frame b engages in front of the fixed frame a, as seen in the Drawing. p is a safety catch or fastening some-what similar to that marked l in Figures 1 and 2. When the moveable frame b and barrel c are turned from the position represented in Figures 11, 12, and 13, to that represented in Figures 10 and 11, the lower part of the said catch or fastening p snaps into a, recess at q (see Figure 13) in front of the fixed body a, and thus prevents the accidental separation of the fixed and moveable parts of the body. By pressing upon the upper part of the catch p its lower part p² is withdrawn from the recess q, and the barrel and moveable frame b, c; may be turned on the axis e to open the body. When after discharge it is wished to extract the cases of the exploded cartridges the barrel c is gripped by the hand and the catch p is pressed upon by the thumb. By a twisting motion the barrel and moveable frame b, c, are turned at right angles to the position represented Figure 10, the pin g working in the cross slot h. By then sliding the barrel and frame b, c, from the fixed body a the revolving cylinder d is moved upon the extractor tube f² to the position represented in Figures 11 and 12, the pin g working in the longitudinal slot h³ in the axis e. The sliding of the revolving cylinder is effected by the back lug i coming against the back face of the said cylinder and carrying the said cylinder with it in its motion. The whole of the cases of the exploded cartridges are thereby simultaneously extracted from the revolving cylinder d. To reload the pistol the barrel c is pushed back and the cylinder d brought against the back of the body a; the barrel c is then turned so as to engage the lugs i, k, with the fixed part a of the frame or body, and securely lock the parts together. The chambers of the revolving cylinder can then be loaded in the usual manner. My improvements may be applied to repeating guns as well as to repeating pistols.

Having now described the nature of my Invention, and the manner in which the same is to be performed, I wish it to be understood that I do not limit myself to the precise details herein described and illustrated, as the same may be varied without departing from the nature of my Invention; but I claim as my Invention of improvements in repeating fire-arms, —

Firstly. Making the rectangular opening in the solid body or frame of the said fire-arms of a length equal to or a little longer than the combined lengths of the revolving cylinder and the cases of the cartridges employed, and causing the revolving cylinder to slide in the said opening in the frame or body for extracting the cases of the exploded cartridges, the parts of the fire-arm being constructed and operating substantially as herein-before described and illustrated in Figures 1 to 6, both inclusive, of the accompanying Drawings.

Secondly. The combination with the said solid body or frame of the fire-arm of an extractor for extracting simultaneously the whole of the cases of the exploded cartridges from the chambers of the revolving cylinder, substantially as herein-before described and illustrated Figures 1 to 6, both inclusive, of the accompanying Drawings.

Thirdly. Making the barrel of the said fire-arms slide in the solid body or frame and carry with it, the revolving cylinder, and support the said revolving cylinder during discharge, substantially as herein-before described and illustrated in Figures 1 to 6, both inclusive, of the accompanying Drawings.

Fourthly. The arrangement or combination of parts, substantiaUy as herein-before described and illustrated in Figures 1 to 6, both inclusive, of the accompanying Drawings, or other equivalent arrangement of parts for locking or fastening the said sliding barrel to the solid body of frame of the fire-arm.

Fifthly. Making the rectangular opening in the solid body or frame of the fire-arm of a length equal to or a little longer than the combined lengths of the revolving cylinder and the cases of the cartridges employed and stationing the revolving cylinder in the said opening, and causing the extractor to move from the said revolving cylinder for extracting the cases of the exploded cartridges, substantially as herein-before described and illustrated in Figures 7, 8, and 9 of the accompanying Drawings. Also the arrangement described and represented in the said Figures 7, 8, and 9 for supporting the revolving cylinder in the frame or body during discharge.

Lastly. The arrangement or combination of parts, substantially as herein-before described and illustrated in Figures 10, 1l, 12, 16, 14, and 15 of the accompanying Drawings, for locking or fastening the barrel to the body, and causing the sliding barrel to carry the revolving cylinder with it for extracting the cases of the exploded cartridges.

In witness whereof, I, the said John Thomas, have hereunto set my hand and seal, this Sixth day of September, in the year of our Lord One thousand eight hundred and sixty-nine.

JOHN THOMAS. (L.S)

Witness,

Henry Skerrett,

Clerk to George Shaw,

Birmingham.