US 11419

UNITED STATES PATENT OFFICE.

JOSIAH ELLS, OF PITTSBURG, PENNSYLVANIA.

IMPROVEMENT IN REVOLVING-BREECH FIRE-ARMS.

Specification forming part of Letters Patent No. 11,419, dated August 1, 1854.

To all whom it may concern:

Be it known that I, Josiah Ells, of Pittsburg, in the county of Allegheny and State of Pennsylvania, have invented certain new and useful Improvements in Revolving-Breech Fire-Arms, applicable to guns, rifles, and pistols; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the annexed drawings, forming part of this specification, and referred to therein by letters of reference, the same letter in each drawing or figure being employed to designate a similar part of the pistol.

My improvements consist in the use of a vibrating stud in the trigger, in combination with a hammer with a chamfered or beveled edge, and with a notch near the extremity of its toe, which is applicable to all kinds of repeating fire-arms, by means of which, by simply pulling the trigger, the hammer is raised to full-cock or fired at pleasure, the stud yielding laterally to allow of the descent of the hammer and recovering its position on the toe of the hammer for repeated action; also, in the use of a double spring to the trigger, for the purposes hereinafter described; also, in the mode of locking the rotating breech at the moment of firing, hereinafter described.

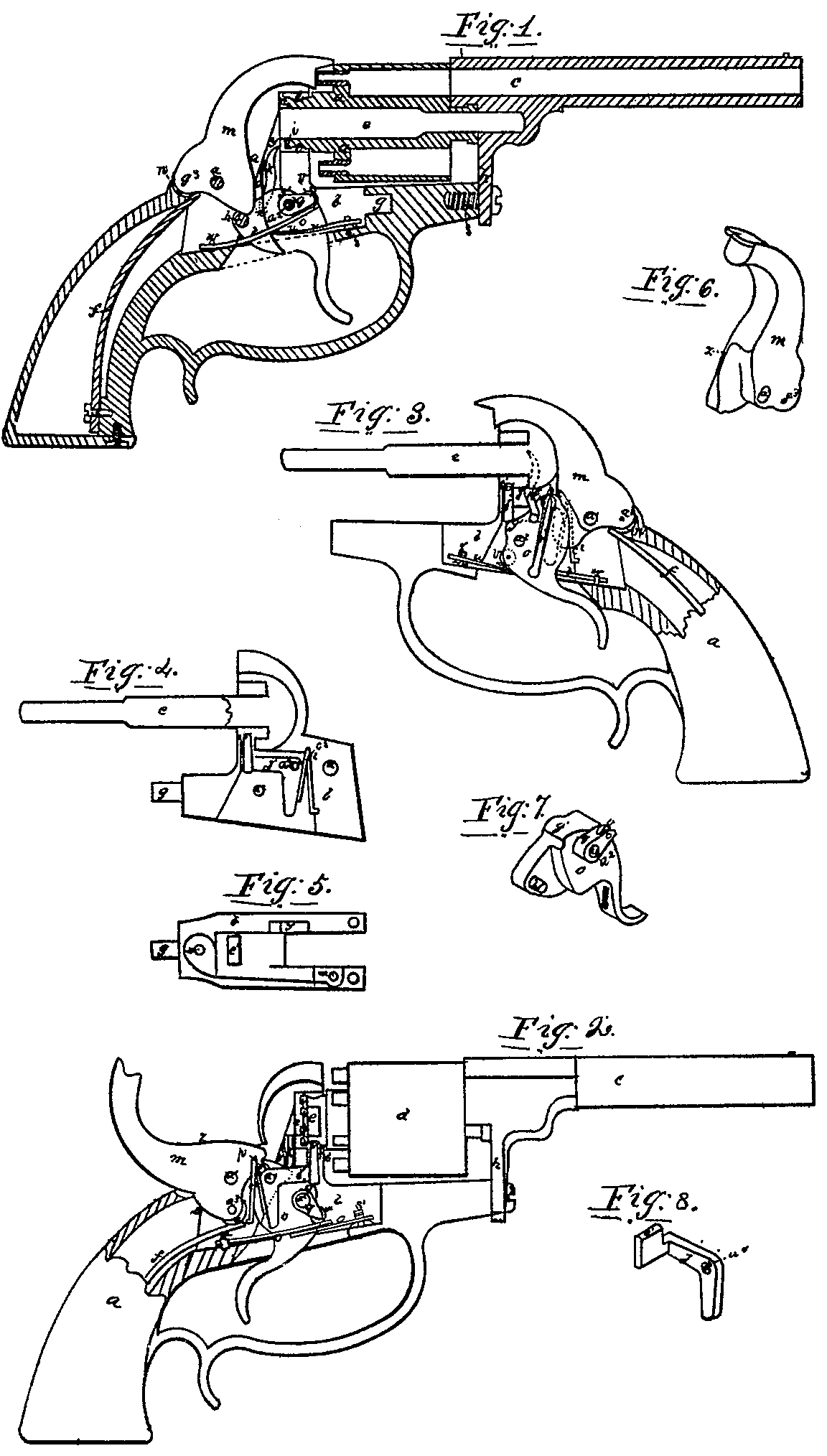

In the drawings accompanying this specification, Figure 1 is a sectional side view of a revolving pistol constructed with my improvements, excepting that the locking-bolt is removed to exhibit the other parts more clearly. Fig. 2 is a side view of a similar pistol, exhibiting the several parts of the lock in their position when the trigger is drawn back and the pistol is cocked ready for firing. Fig. 3 is a sectional view of the stock and lock-frame of the pistol, showing the reverse side of the interior of the lock, the several parts being in their position when the trigger is fully drawn back, immediately after firing and before the trigger is released. Fig. 4 is a sectional view of the lock-frame, with all the parts removed excepting the locking bolt and its spring. Fig. 5is a view of the under side of the lock-frame, all the works of the lock being removed. In Fig. 1 the parts of the lock are in a state of rest in the position they occupy before the trigger is pulled. In Fig. 2 the hammer is raised by the action of the vibrating stud on the cam shaped toe of the hammer and is at full-cock, and the cam-shoulder of the trigger, pressing the level face of the locking-bolt against the squared surface of the neck of the revolving chamber, locks it in its proper position. The slightest touch on the trigger would now fire the pistol. In Fig. 3 the hammer has fallen, and the trigger, if released, would instantly regain its position for repeating the fire. Fig. 6isa perspective view of the hammer, designed to show more clearly the chamfered edge, against which the vibrating stud on the trigger works. Fig. 7 is a perspective view of the trigger, exhibiting the position of the vibrating stud and of the shoulder on which the trigger-spring rests. Fig. 8 is a perspective view of the locking-bolt.

In the several drawings, a is the stock of the pistol; b is the lock plate, constructed in the ordinary manner; c is the barrel; d is the rotating chambered breech, which are constructed and connected together in the manner described in the specification accompanying Letters Patent of the United States granted to me on the 25th April, 1854, and which I need not here more particularly describe.

The spindle e passes through the exact center of the rotating chambered breech d, which revolves around it. The mode of fastening the barrel and breech to the frame of the pistol is, however, somewhat, different to that described in the specification attached to my former patent. The lock-plate b, being of the shape shown in Fig. 4, does not extend as far as the bracket h of the barrel c, but has a projecting pin, g, which enters into a corresponding groove in the pistol-frame. The bracket h of the barrel, being attached to the rotating breech by the tubular extension and sustained by the spindle, as described in my former patent, is fastened to the lock-plate b by a screw, s, which may readily be removed, when the barrel and rotating breech may at once be taken apart.

The shape and construction of the rotating breech dare seen in Fig. 2 and in section in Fig. 1. The neck of the breech enters into a circular recess in the lock-plate around the base of the spindle. (Shown clearly in Fig. 4.)

At the extremity of the neck of the rotating breech are ratchets i i, equal in number to the number of chambers in the breech. These ratchets or projecting points need not project far, being only intended to catch against the point of the finger k, which operates, as here in after described, to rotate the breech. Near the extremity of the neck of the rotating breech c the circumference of the neck, which elsewhere is circular, is of the shape shown at l in Fig. 2, with flattened sides, the number of sides being the same as the number of chambers in the breech, that portion of the rotating breech thus forming a sort of polygonal cylinder, so that a section of that portion of the neck at right angles to the axis of the chambered breech in a pistol with six chambers would give a regular hexagon, there being one flat side immediately opposite each chamber in the breech.

The several pieces of the lock are shown (with the exception of the locking-bolt) in Fig. 1, the locking-bolt with its spring being shown in Fig. 4. The reverse side of the several parts is shown in Fig. 3.

m is the hammer, which turns on the hammer-pin a’. p is the mainspring attached to the lock-frame and passing up through the hollowed stock of the pistol. The extremity of the mainspring rests on a friction-roll, n, at the heel of the hammer, which forces it down when released from the trigger. The under side of the hammer is broad and curved, and comes to a point, or nearly so, at the toe. The front edge of the hammer is chamfered or beveled, and from being broad at the base gradually narrows to an edge at the top of the recess in the side of the hammer, (see Figs. 3 and 6,) made to allow of the passage of the trigger.

The trigger o is of the shape shown in Fig. 7. It works in the lock on the trigger-pin a^2. Near the point the trigger is reduced to half its thickness by a recess made to allow of the passage of the toe of the hammer m. In this recess and near the point of the trigger is the vibrating stud p, which is a short steel rod or stud with a rounded projecting point and flat head inserted in a cylindrical bore in the trigger. It is kept in its place in the trigger by the fine spring r, inserted in a groove in the trigger, (shown in Fig. 3,) the bead of the stud preventing its being forced out of the trigger by the spring r. This stud is fitted nicely into its hole, so that, while it vibrates back and forth when pressed in the direction of its axis, it remains firm when the projecting side of the stud presses against the toe of the hammer. The shoulder q serves as the bearing-point of the spring-lever t, which transmits to the trigger the force of the spring, the spring-lever resting on a friction-roller, v, in the shoulder. The spring-lever t and spring u form a double spring, which is very useful where a strong spring is required and where a good deal of play is also necessary, being more efficient and less liable to get out of order. The arrangement is as follows: The spring-lever t is placed with its point resting on the friction-roll in the shoulder of the trigger, and the other extremity, which has a circular hole through it, slipped over a pin, w, (see Fig. 5,) in the base of the lock-plate. This spring-lever is not screwed or otherwise fastened down, but is kept in place by the point of the strong spring u, the base of which is fastened to the under side of the lock plate (see Fig. 5) by a screw, s’, which screws into a small hole, x.

In Fig. 1 the relative position of the hammer and trigger before firing and the position of the vibrating stud pare clearly shown. The base of the hammer, near its toe, rests on the side of the vibrating stud p. The relative positions of the center-pins a’ and a^2 are so adjusted that when the trigger is drawn back the stud p, pressing on the broad base of the toe of the hammer, raises it up, the hammer as it rises pressing down the mainspring f. As the hammer rises, the turning-point a’ being stationary, the point a, being the center of the friction-wheel at the heel of the hammer which sustains the whole pressure of the mainspring f, gradually descends until the trigger is drawn back so far as to raise the hammer to the point of full-cock, shown in Fig. 2, when the center a^3 is almost immediately under the center a’, thus gradually reducing the effective strength of the mainspring f, so that the force required to raise the hammer gradually diminishes as the hammer rises, instead of increasing, as is ordinarily the case in locks of fire-arms, and at the point of full-cock attained in Fig. 2 a very slight touch on the trigger is enough to fire the pistol, the mainspring f gaining strength or leverage as the hammer falls and exerting its greatest force when the hammer strikes the percussion-cap on the nipple of the rotating breech. When the vibrating stud p has raised the hammer and is drawn a very little farther back than represented in Fig. 2 it slips into a notch near the toe of the hammer (seen in Fig. 3 immediately in front of the vibrating stud) with a slight click, causing a sensation which may be felt by the person using the pistol, and will thus stand at full-cock, although the notch is very slight, because the effective force of the mainspring on the toe of the hammer at that point is very small. If the trigger is now drawn a little farther back to the position shown in Fig. 3, the vibrating stud q will pass out of the notch and over the extremity of the toe of the hammer, thus liberating the hammer, which immediately descends and fires the pistol. So soon as the pressure of the person’s finger is removed from the trigger after firing the trigger recedes, the vibrating stud sliding up the chamfered edge of the hammer until it comes to the position shown in Fig. 3, where the vibrating stud comes to the point on the hammer marked x in Fig. 6, when the point of the stud slips over the thin edge of the hammer and down over its side, the spring r allowing the stud to recede as the thickness of the hammer increases until it reaches the base of the hammer, when the stud slips off its edge and the trigger resumes its place, as shown in Fig.1 with the edge of the stud lying under the toe of the hammer, ready for repeated action.

When the pistol has been fired and the trigger and other parts have resumed their first position it is necessary that before firing again the rotating breech should be turned so far round as to bring the next loaded chamber in a line with the barrel. This is accomplished during the pulling of the trigger for the second fire by means of the finger, which is connected with the trigger by a pin projecting from its side at the lower extremity, which enters into a corresponding circular hole in the side of the trigger between the vibrating stud and the center-pin a^2, The finger k lies in the recess y in the side of the lock-plate. (See Fig. 3.) This recess opens into the circular recess around the base of the spindle e, in which the neck of the rotating breech is inserted. The spring c’ at the back of the finger k presses against the all of the recess and presses the finger forward. When the trigger is not drawn back, as in Fig. 1, the finger & does not come in contact with the ratchets; but as it is drawn back it raises the finger / until it enters the circular recess in which the ratchets ii are situate, and, pressing against one of them, turns the rotating breech just far enough to bring another loaded chamber exactly on the line with the barrel, in which position it is retained, as hereinafter explained, until the pistol is fired and the trigger is again drawn back to repeat fire. By the falling of the trigger after firing the finger & is withdrawn and resumes its first position.

The locking-bolt j, the shape of which is more clearly shown in Fig. 8, is designed to lock the rotating chambered breech in its proper position at the moment of firing, leaving it at all other times free to be rotated by the finger k or by hand at pleasure. In Fig. 4 this locking-bolt j is shown in place in a recess in the side of the lock-plate made for its reception. he spring c^2, which fits into a notch in the all of the recess, presses against the leg of the locking-bolt and presses the head o’ of the bolt through an opening, e’, (see Fig. 5,) into the circular recess around the spindle e. The bolt j is supported and turns on the center-pin a^4. It will be seen by Fig. 8 that the head of the locking-bolt j has a flat surface. This surface rests against one of the sides of the hexagonal part l of the neck of the rotating chambered breech, which enters the recess around the spindle e. (See Fig. 2.) Now, the neck l of the rotating chambered breech having as many sides as there are chambers in the breech, whenever the breech is turned round by hand or otherwise the flat head of the bolt j, pressing (by means of the spring c^2) on the hexagonal neck b, causes the breech always to rest in such a position that one of the chambers is in exact line with the barrel, and the spring c^2 is strong enough to prevent the breech turning round accidentally and yet permit it to be rotated freely when desired. When the trigger is drawn back to the point of full-cock, or nearly so, as in Fig. 2, a hump or cam-shoulder, g’, on the top of the trigger comes in contact with the under side of the head o’ of the locking-bolt, as in Fig. 2, and presses the face of the head of the bolt firmly against one of the flat sides of the hexagonal neck of the rotating breech, thus preventing the possibility of the rotation of the breech during the firing and until the trigger is released. This arrangement is peculiarly convenient, as it enables a person in loading the breech to rotate it freely without touching the trigger, whereas in revolving fire-arms as ordinarily constructed the trigger has to be pulled part way back and held in that position before the breech can be turned.

he advantage of my improved pistol over all other similar fire-arms with which I am acquainted are the great simplicity of construction, which renders them much less liable to get out of repair and miss fire, the great ease and rapidity with which they may be fired, and the fact that they can be made to stand cocked with great ease and by merely palling the trigger, or may be fired immediately without standing cocked, at pleasure.

Having thus described my improvements in rotating-breech fire-arms, what I claim as my invention, and desire to secure by Letters Patent, is—

L. The use of a stud in the trigger vibrating laterally, in combination with a bevel-edged hammer with a notch at its toe, by means of which, by simply palling the trigger, the hammer is raised, and may be either allowed to stand at full-cock or fired at pleasure, while the trigger, after firing, will regain its position for repeated action.

2. The use of a double spring or spring and lever, for the purpose hereinbefore set forth.

3. The mode hereinbefore described of locking the rotating breech at the moment of firing by means of the locking-bolt, in combination with the cam shoulder on the trigger and the hexagonal neck of the rotating breech, which nevertheless permit the breech to be fully rotated by hand or otherwise when the trigger is not drawn back.

Witness my hand this 16th day of June, A.D. 1854.

JOSIAH ELLS.

Witnesses:

Orrin Newton,

John F. Perry.