US 143394

UNITED STATES PATENT OFFICE.

ROLLIN WHITE, OF LOWELL, MASSACHUSETTS.

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 143,394, dated September 30, 1873 ; application filed August 27, 1873.

To all whom it may concern:

Be it known that I, ROLLIN WHITE, of Lowell, in the county of Middlesex and in the State of Massachusetts, have invented certain new and useful Improvements in Revolving Fire-Arm; and do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings and to the letters of reference marked thereon, making a part of this specification. The nature of my invention relates to an improvement in fire-arms; and it consists in the arrangement and combination of parts, which will be more fully described hereafter.

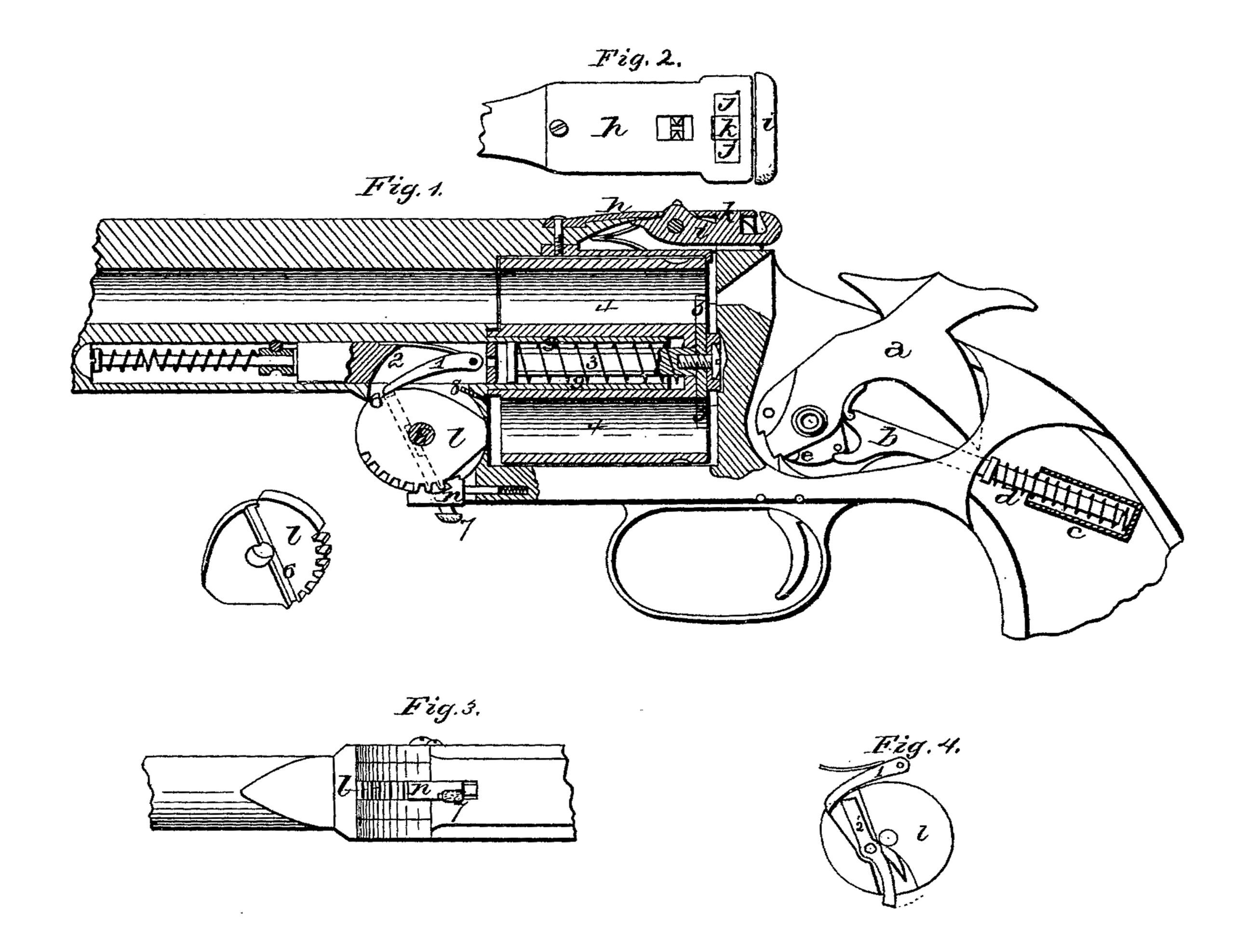

Figure 1 is a longitudinal section of my invention. Fig. 2 is a plan view of the locking- spring. Fig. 3 is an inverted view of my invention, and Fig. 4 a modification of the same.

a represents the hammer or cock, which, instead of being thrown forward by a spring in the usual manner, is operated by the spring-rod b, which extends backward into the handle, and has its rear end held in a socket, c, in which is placed a suitable spring, d. The front end of this rod is bifurcated, the upper branch having a small recess cut in it, which fits over a small projection on the rear of the hammer, and keeps the rod in position, while the lower branch strikes against a projection, e, and regulates the distance which the hammer shall fall. When the trigger is pulled the spring-rod b throws the hammer forward to explode the cartridge, and then allows it to recoil to the half-cock, so that the end of the hammer will not strike against the next cartridge as the cylinder is revolved. The barrel is pivoted upon the pin g,and is locked in position to the top of the breech by the spring-plate h fastened to the top of the barrel, as shown in Figs. 1 and 2. Pivoted in a recess in the rear end of the barrel is the spring-locking bolt i, which catches over the two projections j formed upon. the top of the breech, and which serves to assist in locking the barrel in a horizontal position, and as a lever to raise the spring-locking plate h. As long as this plate is closed down over the projections j on the top of the breech, and the one k on the locking-bolt, the barrel is locked rigidly in position. In raising the bolt upward the plate is raised with it, but just far enough to clear the projections j and unlock the barrel, so that it will tilt downward. Upon the pivot-pin g is placed the toothed cam l, which is turned by the spring-catch n, for the purpose of operating the ejector. Upon its upper edge is formed a square shoulder or recess, o, against which the pawl 1 catches as the cam is moved by the tilting downward of the barrel. This pawl is pivoted to the spring-piston 2, and as the cam pushes the piston backward it strikes against the spring-rod 3 placed. in the cylinder 4, and pushes the ejector 5 outward, and dislodges the shells. Projecting at an angle upward through the spring-catch n, and through the groove 6 cut in the side of the cam l, is the vibrating shipping-stud 7, the upper end of which rests against the under side of the pawl, so that by a slight upward pressure of the finger the end of the pawl is released from the shoulder o, when the spring-piston at once flies back and releases the ejector. As the cam turns backward, carrying the pawl with it, the under side of the pawl strikes against an adjustable stop, 8, (which may consist of a screw or any equivalent device,) which raises the end of the pawl out of the notch, and releases the ejector automatically as soon as it has displaced the shells. By regulating the screw-stop, the point at which this release will take place can be controlled at will. The cartridge-cylinder 4 revolves freely around upon a small cylinder, 9, which projects from the rear end of the barrel, as shown in Fig. 1. Placed in the pivot-hole through the center of the cylinder is the rod 3, having the ejector 5 formed upon its rear end, the rod having a coiled spring placed around it to return the ejector to position after having dislodged the cartridge-shells. This ejector is secured to the cartridge-cylinder alone, and is entirely disconnected from the mechanism for operating it, whereby the cylinder has only to be taken off of its pivot to be cleaned, without unfastening a single part.

Instead of the vibrating shipping-stud 7, shown in Fig. 1, the spring-lever 2’, shown in Fig. 4, may be used, or any other equivalent device which will unship the end of the pawl.

Having thus described my invention, I claim—

1. In a revolving fire-arm, a cartridge-extractor, the stem of which is entirely within the cylinder thereof, and adapted to be operated by a piston projecting within the cylinder, as and for the purposes set forth.

2. In combination with a cartridge-extractor, the stem of which is entirely within the cylinder, a pawl or piston for moving or operating the extractor in the act of tilting the barrel, as described.

3. The shipping-stud 7, in combination with the cam l, pawl 1, and a spring for returning the extractor to its seat, as specified.

4. The adjustable stop 8, for automatically releasing or unshipping the pawl 1 at any desired or predetermined point in the act of tilting the barrel, as described.

5. The cam l, in combination with the pawl 1, stop 8, and piston for operating the cartridge-extractor, substantially as specified.

6. The combination, with a hinged barrel of a fire-arm, of the pivoted spring-locking bolt i having projection k, the slotted spring-locking plate h, and the projections j on the breech, all substantially as and for the purposes herein set forth.

7. The combination of the hammer a and spring-bolt b, having the double bearing shown, whereby a rebounding lock or hammer is obtained, as set forth.

In testimony that I claim the foregoing I have hereunto set my hand this 22d day of August, 1873.

ROLLIN WHITE.

Witnesses:

GEORGE F. RICHARDSON,

AuGUSTUS E. SPALDING.