US 311323

UNITED STATES PATENT OFFICE.

SAMUEL S. HOPKINS, OF NORWICH, CONNECTICUT.

HAMMER FOR FIRE-ARMS.

SPECIFICATION forming part of Letters Patent No. 31,323, dated January 27, 1885.

Application filed November 5, 1884. (No model.)

To all whom it may concern:

Be it known that I, Samuel S. Hopkins, of the city of Norwich, county of New London, and State of Connecticut, have invented certain new and useful Improvements in Fire-Arms, which improvements are fully set forth and described in the following specification, reference being had to the drawings which form a part of and accompany said specification.

My improvements relate more particularly to the hammer of revolving fire-arms and to a means for holding said hammer in a given position while in the act of loading the arm; but they may be also used with advantage in rifles, shot-guns, and in all classes of small-arms.

My immediate object in this invention is to provide a hammer whose so-called “comb” or rearwardly-extending thumb-piece may be folded against or within the hammer proper, when not in use, so that there will be no projecting parts to catch as the arm is entered in a holster or pocket.

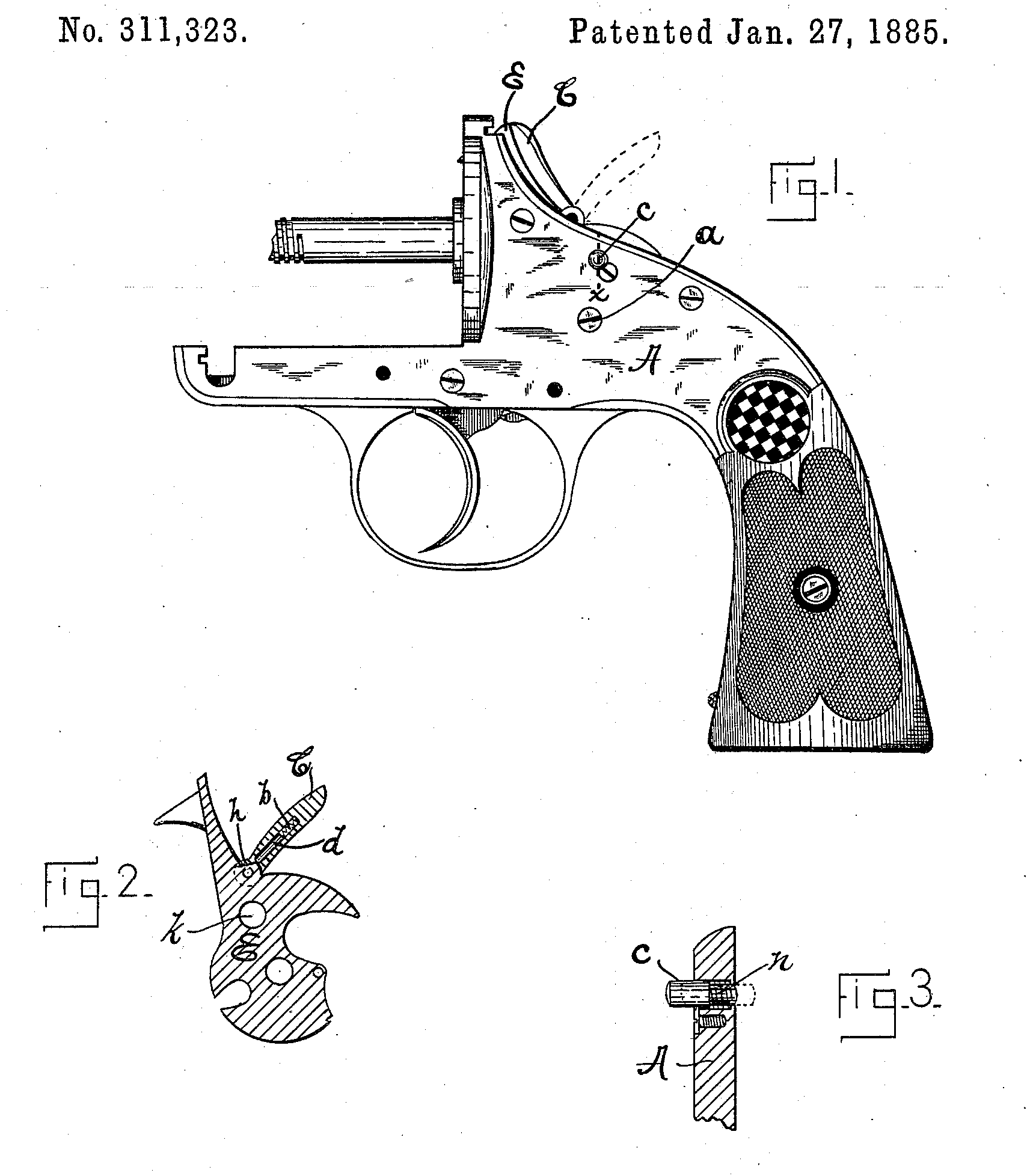

In the annexed drawings, Figure 1 represents a revolver-frame with lock-work assembled and having my improvements attached. Fig. 2 is a sectional view of the hammer detached, showing the spring-pressed plug which acts to retain the comb in its closed position. Fig. 3 is an enlarged cross-section of a portion of one side of the revolver-frame on line x of Fig. 1, showing the plug c, by which the hammer is held in a half-cocked position while loading.

The letter A represents the revolver-frame, and E the hammer, said hammer being supported in said frame by the screw a.

The general form and operation of hammer E, aside from the folding comb, is identical with hammers as now in common use.

In the construction of my new form of hammer the upper portion forward of the arc, which at full cock enters the frame, is either grooved or straddled to form a hinge-joint, in which is fitted the lower end of the comb C. The forward side of comb C is preferably of the same outline as that portion of the hammer which it engages when folded.

As a simple and inexpensive means to retain the comb in its folded position, I have drilled said comb from its lower or hinge end, as shown in Fig. 2, and have inserted therein a spring, b, and plug d, the spring acting with a constant tendency to force the plug forward on the inclined surface h of the hammer, and thus hold the comb in engagement with its Seat, except while in use, as in the act of cocking or partially cocking the arm by hand.

There have been constructed heretofore small-arms having a concealed hammer, and those which, while the hammer proper is in sight, have no comb or thumb-piece by which said hammer may be cocked by pressure of the thumb; consequently such forms of hammers have been available only in self-cocking arms.

If a half-cock or safety-notch is provided in a hammerless self-cocking arm, it is impossible to lower the hammer after loading, and if no half-cock notch is provided there is, so far as I am acquainted with the state of the art, no convenient and safe way to revolve the cylinder to load or to discharge empty shells.

With my present improvement the hammer-nose may be lowered to a safe position between the cartridge-heads as readily as if the hammer was provided with a solid comb, and I am able thus to produce either a double-acting or self-cocking arm without the objectionable projecting solid comb.

When it is desired to construct a self-cocking arm only, the sear may be dispensed with, in which case I provide a spring-pressed plug, c, (see Fig. 3.) at a convenient point in the Side of the frame.

When it is desired to load the arm, the pivoted comb C is opened and the hammer forced rearward until the hole k in the hammer is brought opposite to plug c, when said plug is pressed forward into said hole. The bolt or stop being by this action removed from the cylinder-notches, said cylinder may be freely rotated. After loading, the hammer is forced slightly rearward, when the spring a throws plug c out of hole li, and the hammer may be easily and safely lowered. The comb C is now returned to its closed position, and the arm may be entered in a holster or pocket without fear of accidental discharge by the catching of the hammer-comb.

Having thus described my invention, I claim—

1. A hammer for small-arms (adapted to be pivoted in the frame A) having pivoted to its upper portion a comb or thumb-piece which may be folded against the hammer proper and within or approximately within the frame outline, substantially as described, and for the object set forth.

2. A hammer combining the following elements: the body portion E, adapted to be secured pivotally in frame A, and having a nose to engage and explode a cartridge, a comb or thumb-piece so attached to the body portion E that it may be folded against or within said body portion or may be opened for the purpose of cocking or lowering the hammer by hand, and means for automatically returning the comb C to its closed position, all substantially as described, and for the objects specified.

SAMUEL S. HOPKINS.

Witnesses:

Frank H. Allen,

Tyler. J. Howard.