US 536618

UNITED STATES PATENT OFFICE.

ANDREW FYRBERG, OF WORCESTER, MASSACHUSETTS, ASSIGNOR TO THE HARRINGTON & RICHARDSON ARMS COMPANY, OF SAME PLACE.

EJECTOR FOR REVOLVERS.

SPECIFICATION forming part of Letters Patent No 536,618, dated April 2, 1895.

Application filed September 20, 1894, Serial No. 623,537. (No model.)

To all whom it may concern:

Be it known that I, ANDREW FYRBERG, of the city and county of Worcester and State of Massachusetts, have invented certain new and useful Improvements in Revolvers; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings, forming a part of this specification, in which—

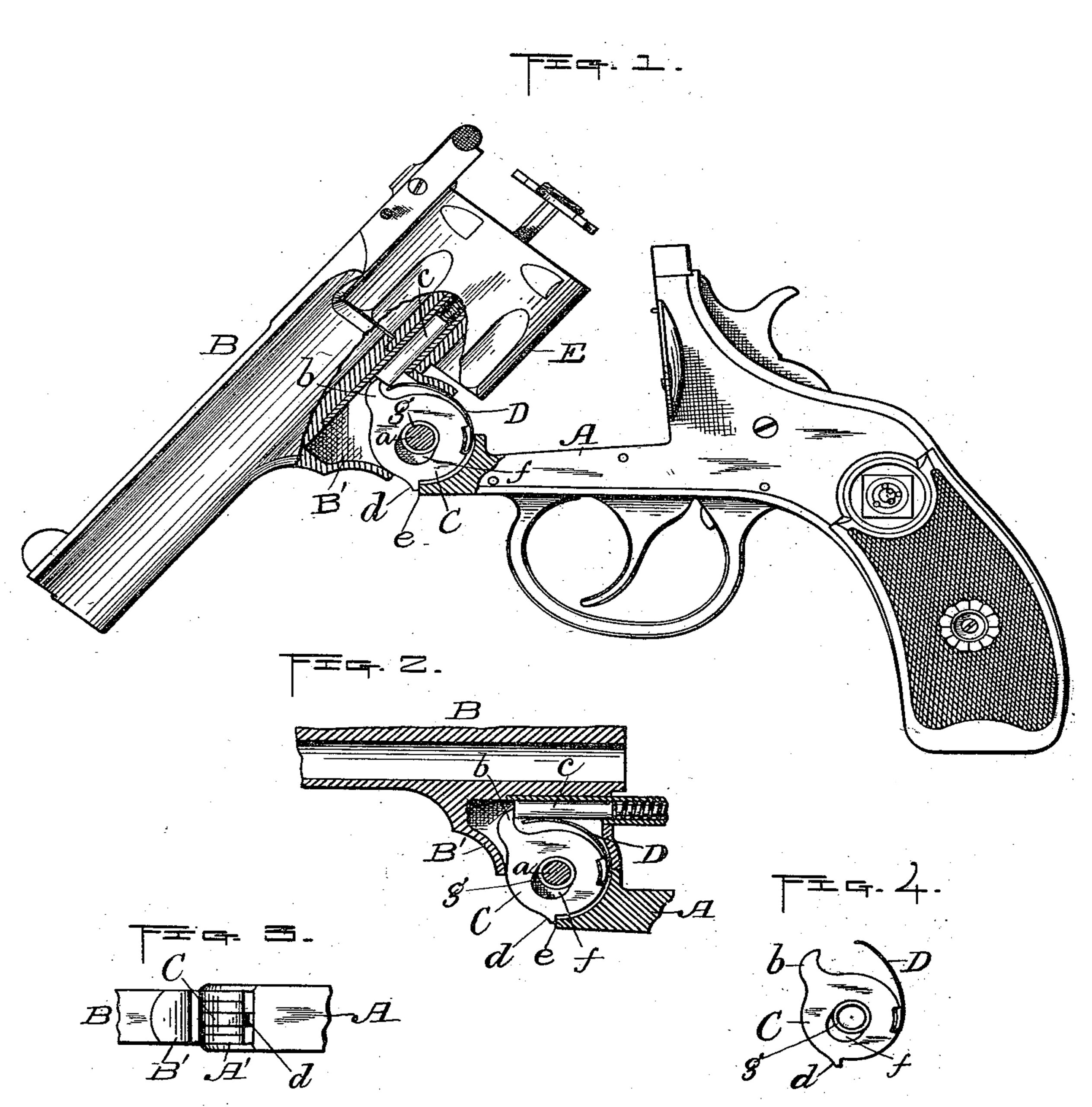

Figure l represents a revolver with the front end partly swung or “broken” down as in practice in the operation of extracting the empty cartridge shells from the cylinder, – part of the side also being partly broken away to illustrate my improvement applied thereto. Fig. 2 represents a vertical section of that portion of the revolver to which said invention relates, showing the parts in their normal positions before the barrel is unlocked and “broken” down as aforesaid. Fig. 3 is a bottom, edge view of the parts shown in Fig. 2, and Fig. 4 is a detached view of the extractor-lifter and its spring, previously alluded to.

To enable others skilled in the art to, which my invention appertains to better understand the nature and purpose thereof, I will now proceed to describe it more in detail.

In the drawings, A represents the revolver-frame, having. the bearing A’ at its forward end to which the base B’ of the barrel B is pivoted by means of the screw a, as usual.

C, is the extractor-lifter, consisting of a circular disk having a hook b adapted to engage with the inner end of the spring extractor-pin c, and an ear or projection d, adapted to engage with the end e, of frame A, to hold said disk from turning in forcing out the extractor to eject the empty cartridge shells by swinging down the barrel in the usual way.

D, is a spring, preferably made of flat wire, and attached to the inner edge or periphery of the disk as convenient point between the lifter-hook b and projection d, substantially as shown in the drawings. Its free end curves up over the disk toward its hook and bears at its outer side upon the under side of the extractor-pin; thus producing a constant friction thereon to hold the same and the cylinder E, to which it is attached, from turning too freely when the cylinder is not locked, or in other words, when the arm is in its normal position ready for raising the hammer preparatory to firing. Said spring not only serves to impart said friction to hold the cylinder from turning too easily; but also, by bearing on the under side of the extractor-pin, as aforesaid, exerts a constant, outward pressure upon the extractor-lifter to hold it so that its projection will always catch and hold against the end e of the frame to lock said extractor-lifter in the usual operation of extracting the empty cartridge shells. To admit of said outward movements of the extractor-lifter, its central opening f is made oblong in shape as is shown in the drawings.

I am aware that it is not broadly new to provide special means for imparting frictional power to hold the cylinder of a revolving fire-arm from turning too easily. I am also aware that extractor-lifters similar in construction and operation to the one herein shown have heretofore been used, having a spring for imparting an outward yielding pressure thereon for the purpose herein stated, and I therefore make no claim to either feature independently. It is believed to be new, however, to so attach and dispose the extractor-lifter spring in the manner herein set forth, whereby the same may be made to serve the double purpose specified.

By said construction and arrangement the mechanism of the revolver to which my invention relates is greatly simplified and improved; is rendered less liable to impairment in use, and when out of order it is simply necessary to remove the pivot screw a to reach the parts for repairs or renewal, without detaching or disturbing any of the other parts of the arm, as is now necessary by the old constructions for effecting the purposes herein set forth. In this instance, I have shown a bushing g, in the opening f of the extractor-lifter, over the transverse screw a, and which I prefer to use in practice, but as it is an inessential feature to the carrying out of my invention, I do not limit myself to the use thereof.

Having now described said invention, what I claim therein as new, and desire to secure by Letters Patent, is——

In a revolving fire-arm the frame A having the usual shoulder e and bearing A’; the barrel B having its base pivoted to said bearing A’ by means of the transverse screw a, said screw, and the spring extractor pin c; in combination with the extractor-lifter C having the projection d adapted to engage with said end e of frame A, and also having the lifting-hook 6 adapted to engage with the inner end to of the extractor-pin c; and spring D, attached at its lower end to the inner edge or periphery of the extractor-lifter, then curving up over said lifter toward its hook and bearing at its outer side against the under side of the extractor-pin, substantially as and for the purpose set forth.

ANDREW FYRBERG.

Witnesses:

A. A. BARKER,

C. FORREST WESSON.