British 1177

(This Invention received Provisional Protection, but notice to proceed with the application for Letters Patent was not given ivithin the time prescribed by the Act.)

PROVISIONAL SPECIFICATION left by Charles Carroll Tevis at the Office of the Commissioners of Patents, with his Petition, on the 17th May

1856.

I, Charles Carroll Tevis, Lieutenant-Colonel, residing at Paris, in the French Empire, do hereby declare the nature of the said Invention for “ An Improved Revolver,” to be as follows:—

My improved pistol is a revolver, in which the ball is subject to compression on being fired (revolver & balle forcee). The discharge is effected by simple pressure, and successive charges may be fired without the necessity of cocking after every discharge, the revolving breech presenting successively different barrels or chambers by the action of the fall of the hammer. The revolving breech can be readily taken out, and replaced without taking the arm to pieces. There is a moveable back plate, so that the charge may be inserted at the back of the breech, and the ball being placed in a chamber at the back of the charge chambers in the breech gets compressed on being fired, as the front of the charge chambers is of less diameter than the rear wherein the charge is inserted. The charge can be easily withdrawn from the rear of the chamber without being fired.

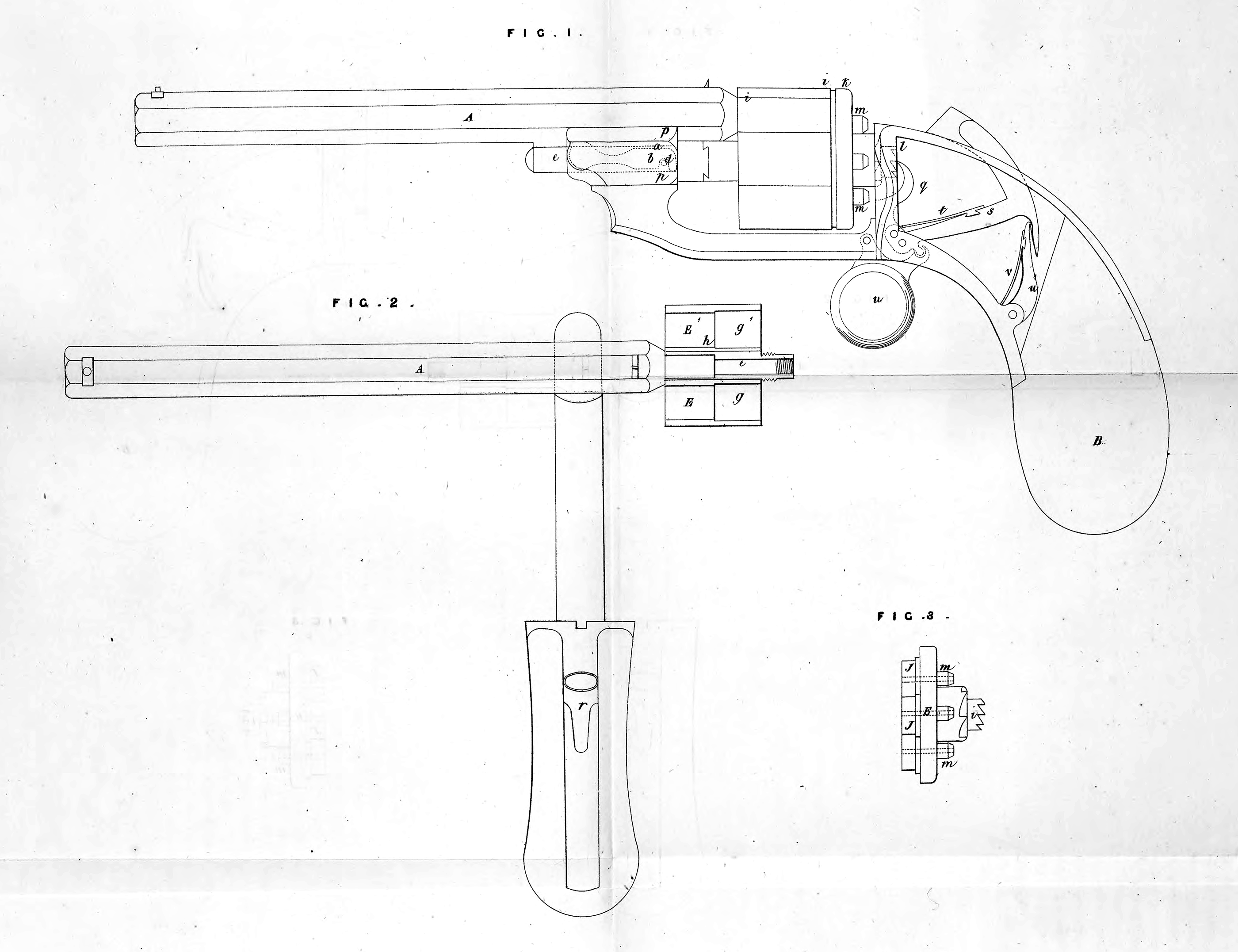

Figure 1 is an elevation of a revolver pistol, constructed according to my Invention, with the butt in section; Figure 2, plan of the revolver prepared to receive a charge ; Figure 3, side view of the back plate of the breech, detached; Figure 4, section through the barrel at the moment of loading; and Figure 5, back view of the breech and of the back plate unscrewed; Figure 6, view of hammer detached. The revolver is composed of two main parts, the barrel A and the butt B. This butt is prolonged in the shape of a rod C, at the end of which is a piece D, free to move and describe a fourth of a revolution round the point d as a centre. A locking lever 6, moveable round the point c, is fixed to this piece D, and comes down over a stud d on a spindle e, which forms the axis for the breech E, and is placed under the barrel, so as to fix it to the butt B by sliding it into the piece D, there becoming locked by the locking lever and stud. The breech E is composed of several barrels or tubes E\ E1, united round a hollow tube, which fits over the spindle e. Each of the barrels is formed at back with a chamber <7, g, of greater diameter than the front part thereof, and in these chambers the powder and ball are placed. A back plate F is screwed upon the threaded end of the spindle e, and is connected to the breech by a rod K, which is free to slide into an orifice at t, but cannot get quite out of it; it may be raised or pressed in, according to the position of the back plate F. The plate F is provided with as many projecting necks J, J, as there are barrels in the breech, and each neck is formed to fit hermetically into its corresponding breech barrel. A ratchet is fixed at the centre and at the back of the plate F, with as many teeth as there are barrels in the breech. Each of the projecting necks communicates through a channel with a nipple for receiving a percussion cap. The breech is, under ordinary circumstances, moveable, but it may be fixed on the spindle, when, by turning it by hand, it will cause the spindle to revolve with it, and thus unscrew the back plate F, which opens to allow of the breech being charged. On turning the breech in a contrary direction the back plate will be screwed on, and the necks J, J, will hermetically close the back of the breech barrels. A wooden case covers the mechanism in the butt, and when the breech is in position and fastened by the locking lever, the back tumbler rests against a rod q, which acts as a stop. The hammer r is fixed on the end of a rod s, kept back by a spring t. The tail of the hammer has a notch which hooks into u, which is distended by the spring v. The tumbler u acts upon the rod s, wdiich pushes the hammer forward to fall upon one of the nipples, and at the same time upon the lever q, which drops, and carrying with it one tooth of the ratchet, causes the breech to make a partial revolution, and present another nipple ready for the next action of the hammer, while the hammer falls back and resumes its former position. In Figure 7 a modification is shewn, in which the spindle e has two buttons z> z\ and is split at its end. Tho mechanism C may be placed under the butt instead of within it.