USA 13039

UNITED STATES PATENT OFFICE.

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 13,039, dated June 12, 1855.

To all whom it may concern:

Beit known that I, Frederick Newbury, of the city of Albany, State of New York, have invented an Improvement in the Construction of Fire-Arms having revolving many-chambered cylinders for loading, such as Colt’s, Allen’s, and others, the said improvements being employed with the cylinder, having for its object to prevent the clogging up of the working parts of the cylinder so as to prevent its revolution by the fragments of the metallic cap scattered in its detonation—a matter of frequent occurrence in the use of revolvers.

I declare the following specification, with the drawings hereto attached as part of the same, to be a full and complete description of my invention, which I call “Newbury’s Priming-Cap Guard.”

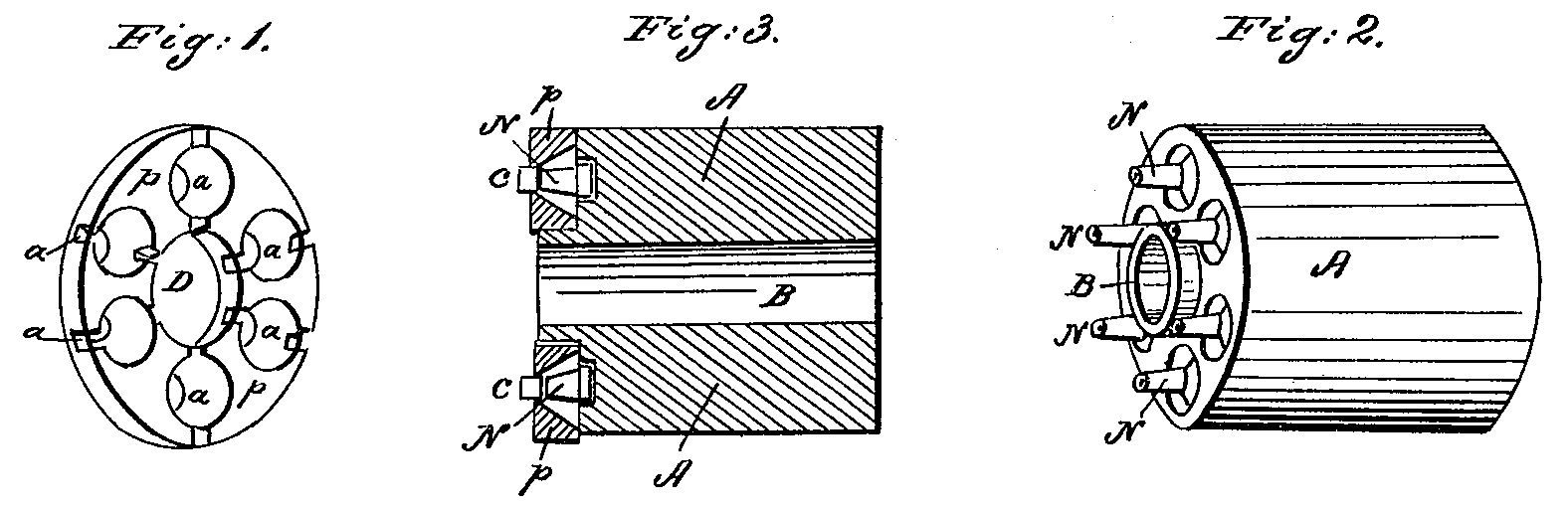

Figure 1 represents the guard in perspective. Fig. 2 represents in perspective a six barreled chambered cylinder. Fig. 3 represents a section of the cylinder through it axis of rotation, with the guard applied to it.

Similar letters in the different figures denote the same parts of the apparatus.

A is the cylinder; B, the bore or socket for the mandrel on which the cylinder revolves; N, the priming-cones with the caps c upon them.

The guard is an annular plate of metal, P, in thickness nearly equal to the projection of the cones from the face of the cylinder. It has a central opening, D, for the passage of the mandrel, and within the annular space lying between the opening D and its periphery openings a a are made, properly placed to pass the priming-cones through. Each of these openings a a is a chamber of a conical or cup form, whose outer or smaller end is just large enough to pass freely the percussion-cap as it lies on the cone, the inner end flaring as large as can be conveniently made in the ring to apply round the base of the cone N. The plate P lies flat upon the end face of the cylinder A, and its thickness is such as to allow the cap c to project beyond its outer face, so as to permit the hammer of the lock to explode it with certainty.

Each conical chamber a has nicks, as shown in Fig. 1, taken out of its edges, one opening out through the outer edge of the plate and the other into the inner or mandrel hole, these openings operating as vents for the gas produced by the explosion of the cap.

From the above description of the apparatus it will be manifest that whenever a cap is exploded its fragments will drop into the chamber at and remain there without the possibility of any portion escaping therefrom during the firing of the weapon. Whenever, for the purpose of reloading, the cylinder is withdrawn, the guard being raised off the cones, all the remains of the caps can be emptied out, and so all possibility of any obstruction to the free working of the cylinder from fragments of caps be done away.

The plate P may be attached to the stock by catches or detents, which, being attached to the side of the stock, hold into a groove cut around the periphery of the plate P, permitting the plate (guard) to revolve freely within the gripe of the detents. In that case the withdrawal of the cylinder would leave the guard attached to the stock and save the time required to remove it by hand, as just described, for then the mere turning down of the stock would empty the chambers of the cap-fragments.

I claim—

In fire. arms having revolving cylinders to carry their load and priming, the construction and use of a guard to prevent the fragments of exploded priming-caps from impeding the rotation of the cylinder by covering up the cones with a movable metallic ring, containing for each cone a chamber as large as can be conveniently made within the ring to inclose each cone, each chamber having an aperture to permit the priming-cap to pass through, and also having lateral openings to pass off the gas produced by the detonation of the cap, the whole substantially as set forth in the above specification.

F. NEWBURY.

Witnesses:

Richd. Varick De Witt,

W. C. Miller.