US 9922

UNITED STATES PATENT OFFICE.

GEORGE LEONARD, OF SHREWSBURY, MASSACHUSETTS,

IMPROVEMENT IN FIRE-ARMS.

Specification forming part of Letters Patent No. 9,922, dated August 9, 1853.

To all whom it may concern:

Beit known that, the undersigned, George Leonard, of Shrewsbury, in the county of Worcester and Commonwealth of Massachusetts, have invented a new and useful Improvement in Fire-Arms, embraced in a pistol, of which the following is a full and exact description.

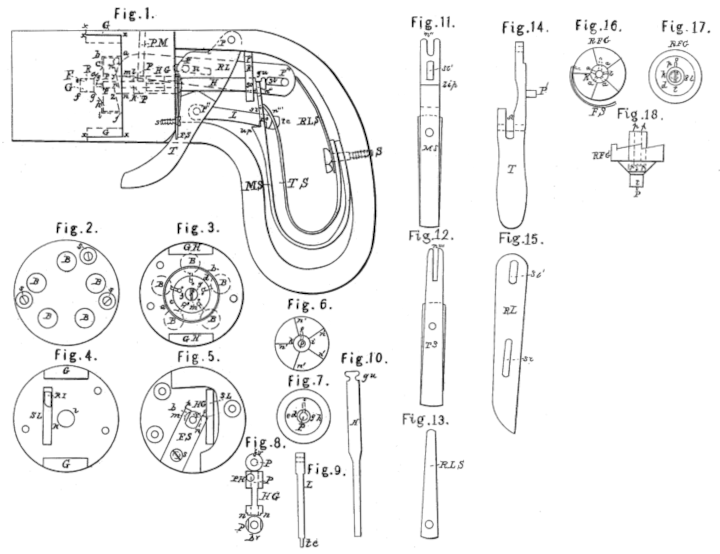

It bas-five barrels in one piece, x x x x x x x x Figure 1. A front view of each barrel B B B B B is exhibited in Fig. 2, and their position from behind is marked by the dotted circles in Fig. 3. The barrels are attached to the stock by three screws, s s s, Fig. 2, and are kept in a true position by two guides, G G, on the stock, Figs. 1 and 4, which enter the guide+holes G H and G. H, Fig. 3. In the center of the posterior part of the barrels a cavity, a b c d e f g h i j, Fig. 1, and a b, Fig. 3, is perforated. Around the center of the beveling part of this cavity c d and g h, Fig.1, and c d, Fig. 3, five small holes, o o o o o, Fig. 3, for communicating fire are drilled into the back of each barrel. Within said cavity turns a piece called a “revolving cone” in my caveat, the receipt of which was acknowledged April 8, 1850. This piece I now call a “revolving fire-guide”— a name which I regard as more general and descriptive. A side view of the revolving fire+guide R F G, Fig. 1, is delineated within the above-named cavity by tie heavily-dotted lines ending at k l. A back view is shown in Fig. 6 and a front view in Fig. 7. A ratchet is cut on the back face with five notches, n’ n’, Fig. 1, and n’ n’ n’ n’ n’, Fig.6, in which the ratchet-lever R L, Figs. 1 and 15, operates. A circular hole, p p p p, Fig. 1, and p, Fig. 6, is drilled into the center of the back projection, in which the front, and smallest part of the cylindrical hammer H, Fig. 1, plays. At the bottom of this hole a small hole for communicating fire is drilled out to o, Figs. 1, 6, and 7, at the middle of the beveling portion c d and g h, Figs. 1 and 7. This small hole o exactly corresponds to the small holes o o o o o, Fig. 3, when brought into proper position by the ratchet-lever in operating the pistol. The cylindrical back projection, k l y z, Fig. 1, of the revolving fire-guide, a back view of which is shown by kl, Fig. 6, is confined and revolves in a circular perforation in the stock k l m n, Fig. 1, and k l, Fig. 4. The cylindrical front projection, d e f g, Fig. 1, and dig, Fig. 7, is confined and revolved in a circular perforation, d e f g, Fig. 1, and f g, Fig. 3, in the center of the barrels.

The hammer-guide, a side view of which is shown by HG, Fig.1, a front view by f v, Fig. 8, a back view by b , Fig. 8, and an oblique bird’s-eye view by H G, Fig. 8, exactly fits the back projection of the revolving fire-guide, and is held against it with force sufficient to keep it in place by the friction-spring, F S, Figs. 1 and 5, except when it is forced around by the ratchet-lever. It has a longitudinal perforation, p p p, Fig. 8, of a size to receive and guide the hammer. The friction-spring is held to the stock by the screw s, Figs. 1 and 5. It has two projections, p p, Fig. 5, which fail in to the notches in , Figs. 5 and 8, and hinder the hammer-guide from turning, so that the priming-hole P H, Fig. 8, for admitting the priming-pills is always held so as to exactly correspond to the lower end of the priming-magazine P M, Fig. 1.

The priming-magazine P M, Fig.1 is drilled out through the solid part of the stock downward, so as to correspond to the priming-hole.

The trigger, a side view of which is exhibited by T, Fig. 1, and a back view by Fig. 14, turns on a pin, P, Fig. 1, fastened in the top of the stock. It has a pin, P’, Figs, 1 and 14, beneath its front part, which fits into a slot, s l, Figs. 1 and 15, in the ratchet-lever to operate it. The trigger has a slot, s l, Fig. 14, in which the lever I, Figs.1 and 9, is confined by the pin P” Fig.1. The back of the lever passes through a slot, s l”, in the mainspring, Figs. 1 and 11, and has a notch, no, Fig. 1, which catches onto the bottom of the slot in the mainspring, and by which the main spring is forced back. At the posterior extremity of the lever is a tenon, t e, Figs. 1 and 9, against the shoulders of which the sides of the slot or notch n”” in the trigger-spring, Figs. 1 and 12, bear.

The hammer H, Figs. 1 and 10, is a cylinder of unequal diameter. The smaller part plays through the hammer-guide into the revolving fire-guide. The larger part slides through a socket, s o, Fig. 1, drilled through a projection from the stock P R, Fig. 1. A gutter, g u, Figs. 1 and 10, is turned around the posterior portion, so as to be received into a notch or slot, n'”, in the mainspring, whereby it is drawn back and forced forward.

The ratchet-lever R L, Figs. 1 and 15, has two slots, s l and s l’. The slot s l’ fits onto a pin, P'”, Fig. 1, in the stock. The slot s l receives the pin P’ in the trigger, by which the anterior end is moved by drawing back the trigger, so as to turn the revolving fire-guide one-fifth of a circumference. The anterior end is kept in place by its passing through a slot, S L, Figs. 4 and 5, in the stock.

The mainspring M S, Figs, 1 and 11, trigger-spring T S, Figs. 1 and 12, and ratchet-lever spring R L S, Figs. 1 and 13, are all fastened to the back of the stock by the screw S, Fig. 1. The mainspring fits the hammer and lever, as before described. It has a lip marked l i p, Figs. 1 and 11. This lip, when the mainspring is drawn back, partially revolves, so that the front edge of the lip rises and lifts the lever, when the notch n o, Fig. 1, slips from the main-spring, which then drives the hammer forward. The trigger-spring has a slot, or notch, n'”, Figs. 1 and 12, which fits on to the tenon of the lever t e, Figs. 1 and 9, and bears against the shoulders of the tenon on each side. The ratchet-lever spring R L S, Figs. 1 and 13, bears against the back end of the ratchet-lever and keeps it forward, but yields enough for the ratchet-lever to rise over the inclined plane of a notch in the ratchet.

The pistol is operated as follows: The trigger is drawn back by the finger. The notch in the lever drives back the mainspring, which carries back the hammer. At the same time the pin P. carries down the point of the ratchet-lever and turns the revolving fire-guide. When the hammer is nearly back one of the percussion-pills in the priming-magazine drops into the hole in the hammer-guide. The motion of the trigger being continued, tine lip of the mainspring lifts off the notch of the lever, when the mainspring drives forward the hammer, and the pill is exploded in the bottom of the hole p p p p, Fig. 1, in the revolving fire-guide. The fire is guided through the small hole o, Figs. 1, 6, and 7, in the revolving fire-guide into one of the five small holes into the guide into one of the five small holes into the the barrel is discharged. The finger being now released, the trigger-spring drives back the lever, trigger, and ratchet-lever into their first position.

The revolving fire guide is the part I wish to patent, and for which I shall shortly make specific claim; but as a great variety of these can easily be constructed varying in shape, proportion, and number of parts and adjuncts, I am desirous of describing one variation which I have made, at first sight different, but identical in principle. It consists of a cone or port, P, Fig. 18, a side view being here represented by the heavy lines. A front view is represented by the heavy circular line k l, Fig. 17, and a back view by the heavy circular line k l, Fig. 16 A circular hole, p p p p, Fig. 18, and p, Figs. 16 and 17, is drilled into the center as far as the similar hole is in the first-described revolving fire-guide. At the bottom of the hole five small holes, a a a a a, Fig. 16, are drilled through to the outside, one-fifth of the circumference of the port from each other, for the purpose of communicating fire successively to the several barrels. This port has a tenon, t, Figs. 17 and 18, at the bottom, which fits into a mortise, m o, Fig. 3, in the bottom of the cavity, drilled for the reception of the front projection of the before-described revolving fire-guide. This tenon keeps the port in such a position that each of the five small holes is just opposite the five small holes in the back of the barrels for communicating fire to the charges. Around this port revolves a piece or revolving fire-guide, R F G, Figs. 16, 17, and 18, which is the exact complement necessary to complete a revolving fire-guide of just the same size and form as the one first described, except that this piece has a friction-spring, F S, Fig. 16, to hinder the piece from slipping when the ratchet-lever is carried back. At each time this piece is carried round by the ratchet-lever one-fifth of a circumference the small hole o, Fig. 17, drilled through the center of the beveling-portion, is brought into exact coincidence with one of the five small holes in the port, and one of the small holes communicating with a barrel, so that the fire carried as before. This port and revolving fire-guide was called a “single cone with an intermediate revolving piece” in my caveat, the receipt of which was acknowledged April, 8, 1850.

What I claim as my invention, and desire to secure by Letters Patent, is—

A revolving fire-guide which by the continued operation of the fire-arm shall successively communicate fire to the different charges of several barrels.

GEORGE LEONARD.

In presence of—

Elizabeth Davis,

Job E. Stone.