US 425979

UNITED STATES PATENT OFFICE.

HOMER M. CALDWELL, OF WORCESTER, MASSACHUSETTS, ASSIGNOR TO THE HARRINGTON & RICHARDSON ARMS COMPANY, OF SAME PLACE.

FIRE-ARM.

SPECIFICATION forming part of Letters Patent No. 425,979, dated April 22, 1890.

Application filed November 23, 1889. Serial No. 331, 278. (No model.)

To all whom it may concern:

Be it known that I, HOMER M. CALDWELL, a citizen of the United States, residing at Worcester, in the county of Worcester and State of Massachusetts, have invented certain new and useful Improvements in Fire-Arms, of which the following, together with the accompanying drawings, is a specification sufficiently full, clear, and exact to enable persons skilled in the art to which this invention appertains to make and use the same.

One part of my present invention relates to the construction of the lock or action mechanism in that class of fire-arms known as “double-action” revolvers.

One object of this invention is to combine in a double-action revolver a pivoted sear and rebounding mechanism in the same action.

Another object is to provide a more efficient and serviceable mechanism, one in which the parts operate with freedom and smoothness, and wherein the hammer when cocked automatically by pull on the trigger will have approximately the same range or extent of movement as when cocked by the thumb.

Another object is to provide a construction wherein the pivoted sear and rebounder are disposed within a recess in the end of the guard, thus affording greater facility in constructing and assembling the parts. Another part of my invention relates to the structure of the catch, intercepting-block, or dog that works in conjunction with the finger-disk for retaining and releasing the shell-ejector, the objects being to provide an interceptor or catch that is fitted to the frame by intermatching ribs and grooves at its sides parallel with the direction of movement, and so constructed that the parts will not become loose and uncertain in action or be liable to escape from the notch of the finger-disk, except when properly forced back; also, to provide a locking-lever or stop-dog for retaining the intercepting-block at forward position until the same is released by the swinging down of the barrel. These objects I attain by the mechanism shown and described, the particular subject-matter claimed being hereinafter definitely specified.

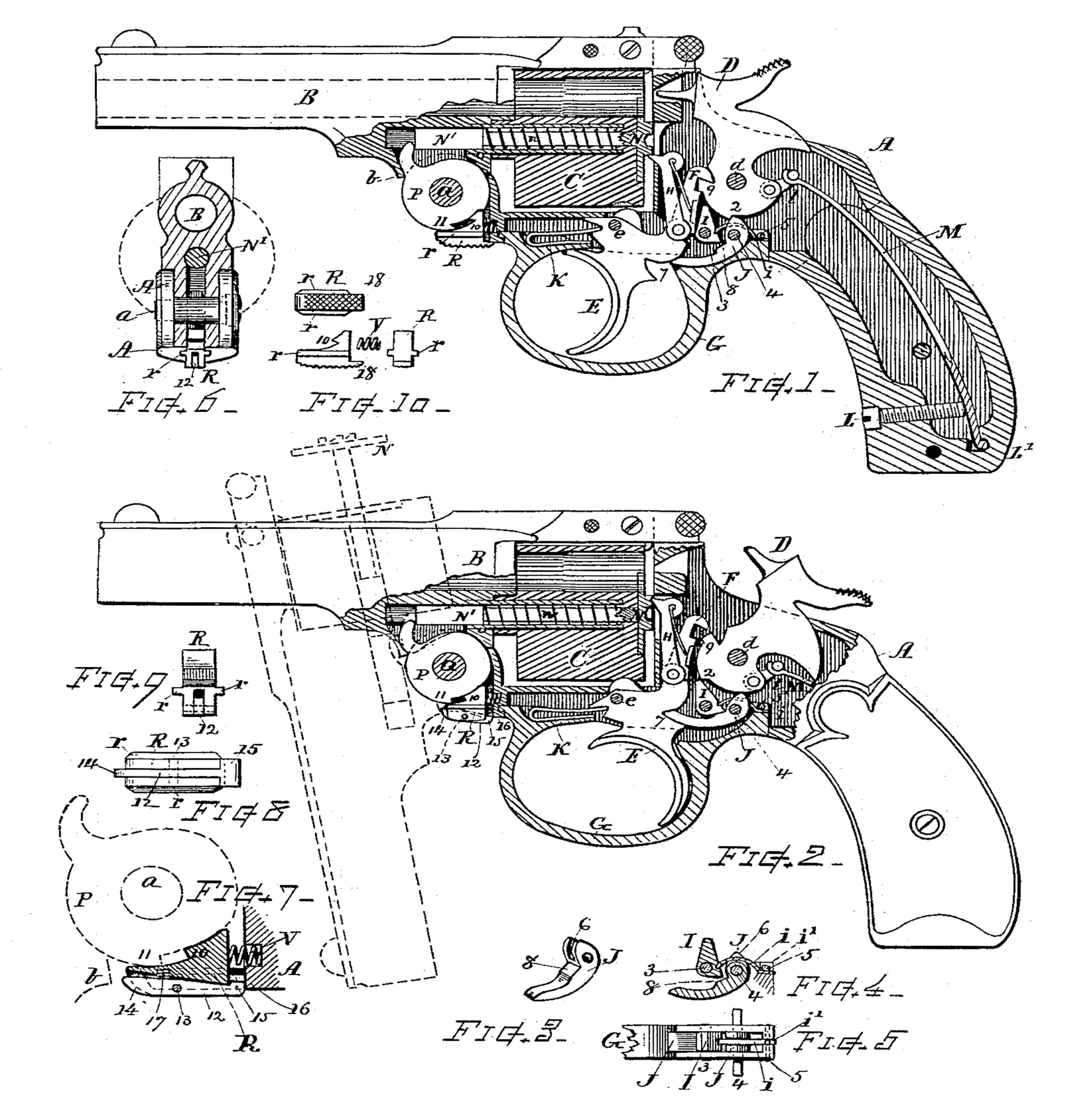

In the drawings, Figure 1 is a sectional view of a revolver, illustrating the nature of my improvements, the hammer being at normal position as retained by the rebounder. Fig. 2 is a sectional view showing the hammer at full-cock and the sear just leaving the notch of the tumbler, as at the instant of discharge. Fig. 3 is a perspective view of the rebounder separate from other parts. Fig. 4 is a section of the rebounder, the pivoted sear, and its spring. Fig. 5 is a top view at the rear end of the guard, showing the manner in which the sear, rebounder, and sear-spring are assembled therein. Fig. 6 is a view of the end of the frame, with the barrel-hinge in section and the finger-disk removed, for showing the manner in which the intercepting-block or catch is arranged in combination with the fore end of the frame. Fig. 7 is a vertical longitudinal section, on a larger scale, showing the intercepting-block, its locking-lever, and spring. Fig. 8 is a bottom view of said block. Fig. 9 is an end view of the same; and Fig. 10 shows in detail a modified intercepting-block, which is made without the locking-lever.

Referring to parts, A denotes the frame; B, the barrel; C, the cylinder; D, the hammer, pivoted at d within the frame; E, the trigger, pivoted on the pin e, and having hinged to its rear extension the hand-lever or pawl H for rotating the cylinder, and the lifter F for throwing back the hammer automatically by pull upon the trigger. All of the above-named parts can be constructed and arranged in well-known form or substantially as shown.

As an essential feature of my invention I employ, combined with the trigger E and hammer D, a pivoted sear J and a rebounder J, which parts are best disposed assembled within a recess at the rear end of the guard G, the parts being preferably located in such manner that the sear I and rebounder J will severally engage the hammer on a single notch 2, one when the hammer is cocked and the other when the hammer is down.

The sear I is made in somewhat triangular shape, pivoted at its front lower part upon a pin 3, that passes through the upper part of the guard G, while the rebounder is pivoted upon a pin 4, that passes transversely through the guard G and frame, and which serves to hold the guard in connection with the frame, and also as a pivot for the rebounder.

The sear-spring i is composed of a curved piece of flat metal, and has its rear end fitted in a notch i’ at the upper rear part of the guard, where it is confined by means of a pin 5, said spring passing across the top of the rebounder, which latter is recessed or slotted, as at 6, for its accommodation, and the front end of said spring engages a notch in the rear side of the sear in the manner illustrated. The spring K for throwing forward the trigger is the same as heretofore employed.

The front end of the rebounder J engages with a notch 7 in the back of the trigger, whereby said rebounder is raised and depressed by the trigger movement. The top of the rebounder is provided with a seat or bearing-surface 8 forward of its pivot, that engages the rear part or angle of the sear I when said rebounder is lifted, and by lifting said rear part swings the top end of said sear away from the notch 2 on the hammer just at the instant the trigger reaches its backward limit of action.

The lifter F has a shoulder and hook at its upper end, that engages a projection 9 and notch on the front of the hammer-tumbler and automatically lifts the hammer as the trigger is pulled backward until the shoulders at the hinging-joint that connects the trigger and lifter swing into contact with each other. Then further movement of the trigger swings the lifter forward, throwing its shoulder and hook off from the tumbler and allowing the hammer to be projected forward by the mainspring M. This method of combining the lifter and hammer has been employed heretofore, but not in combination with a rebounder and sear.

The mainspring M, as usual, has its upper end joined to the hammer-tumbler by a stirrup l, (or combined in other suitable manner,) and its lower end fixed by interlocking in a notch in the frame at L’, a screw L being provided for giving the desired degree of tension therefor.

In the operation, when the piece is cocked by the thumb, the hammer is swung back until its notch 2 passes the end of the sear I, and said sear is caused by its spring i to fall behind the notch, and thus hold the hammer elevated at full-cock. Then, as the trigger is pulled back, the notch in its rear side engages with and lifts the forward end of the rebounder J, and as the rebounder moves upward the surface or part 8, coming into contact with the corner of the sear, swings the latter on its pivot and forces the’ sear-point off from the notch of the tumbler and allows the hammer to be thrown forward by the action of the main-spring for firing the cartridge. When the trigger is again swung forward by its spring K, the forward end of the rebounder is depressed, and the rear end of said rebounder, being in engagement with the notch 2 of the hammer-tumbler, advances and effects the rebound of the hammer to the position indicated in Fig. 1.

By the construction above described I attain the advantages of both the sear and the rebounder in the same arm, thus producing a better and more efficient action, one in which the movement is accomplished with greater ease and smoothness than is ordinarily attained for the automatic part of the double action, and giving a lock that is not liable to miss fire.

Another of the advantages incident to this invention is, that the movement of the hammer when forced back automatically by a pull on the trigger is to substantially the same extent as when the hammer is drawn back by the thumb, thus delivering a strong blow upon the cartridge as it descends and avoiding liability of misfire by weakness of the double-action stroke, the variation between the automatic and thumb-action stroke being only that occurring while swinging the point of the sear off from the notch 2.

Other advantages are, that only one notch is required, the point of the sear can be made thick and substantial, and the necessity for delicate construction is obviated, thus producing a more durable action and one less liable to accidental derangement or fracture.

I am aware that a rebounder has heretofore been employed in double actions in which there was no pivoted sear, and also that sears are old in double actions wherein no rebounder is employed; but the employment of a pivoted sear combined with a rebounder in one and the same double-action mechanism is a feature of my invention.

The shell-ejector N, its spindle N’, and spring n are of the well-known type, as shown, and arranged to be operated by a disk P, fitted in the hinging-joint, and having a finger that throws up the ejector when the barrel is swung downward on the hinging-axis a. The catch or intercepting-block R for retaining and releasing the disk P is disposed within a recess in the fore end of the frame A beneath said disk. The block and frame are fitted together with intermatching grooves and ribs r at the opposite sides, the ribs extending parallel with the direction of movement, and the grooves and ribs together forming supporting-guides that sustain the block in an efficient manner, while allowing it to slide back and forth freely within its limit of action. The front side of the block is curved and provided with a notch or offset 10 for intercepting the rotative movement of the finger-disk P, which latter is furnished with a corresponding offset or notch 11, as indicated. The rear side of the intercepting-block R is cut off short and square, and a spring V is introduced between it and the end of the frame for forcing it forward, so that its notch 10 will normally engage with the notch 11 of the finger-disk.

Within a longitudinal recess in the intercepting-block I arrange a bar or lever 12 pivoted as at 13, (see Fig. 9), and having its front end, which is best rounded or inclined, as at 14, projecting slightly beyond the front end of the part R, while its rear end is furnished with a lug or head 15, that fits into the recess or space between the frame and intercepting-block when the latter is at forward position, but which lug will come out of the recess and slip past the angle of the frame at 16 when the front-end 14 of said lever is pressed upward either by the shoulder b of the barrel-hinge or by the thumb of the operator. A small spring 17 is provided for pressing upon the lever in a manner to force its head or lug into the recess. The end 15 of the lever stops the opening in the frame, and also locks the intercepting-block, so that it cannot be forced backward, until the lever is raised. In the operation of these parts, when the barrel is tilted forward, the notches 10 and 11 interlock and the intercepting-block arrests the movement of the finger-disk until the shoulder of the barrel-hinge strikes the latching-lever, and by throwing up the front end 14 of said lever disengages its head or lug 15 from the angle 16 of the frame. The action of the retractor-spring n then causes the finger-disk to instantly force back the intercepting-block, disengaging the notches 10 and 11, and thereby permitting rotation of the finger-disk and the throwing down of the ejector. When the barrel is swung back into normal position, the finger-disk is rotated so as to bring its notch 11 past the notch 10 of the intercepting-block, and the latter is thrown forward by its spring V, so that the head of the lever 15 can drop into the space, and thus again lock the intercepting-block in place ready for the next operation.

By means of the latching-lever the intercepting-block is locked, so that there is no liability of the notches slipping off and releasing the finger-disk until said lever is pressed up by the shoulder of the barrel or by the thumb of the operator.

In Fig. 10 I have shown an intercepting-block made without the latching-lever, but having the feature of the side ribs r. This form can in some instances be employed. It is best check-marked on the bottom, so that it can be moved by the thumb, and also fitted with a backward extension 18 to cover the slot in the frame.

I am aware that an intercepting device for holding a finger-disk having a notch in somewhat similar form to that shown has been heretofore employed; but such former device was supported in the frame by a long stem and not by means of side ribs and grooves, and it was imperfect in that it soon became loose and uncertain in ifs action, and also could not be used in a short frame forward of the head of the guard G, both of which objections are overcome by my improved construction.

I claim as my invention herein, to be secured by Letters Patent—

1. In a double-action-revolver lock mechanism, the combination, with the trigger and hammer, of a pivoted sear and rebounder severally located in rear of the trigger beneath the hammer, with their points or engaging ends at positions for respectively engaging with the hammer-tumbler, one when the hammer is raised and the other when the hammer is down, substantially as set forth.

2. In a double-action lock mechanism, the combination, with the hammer, the trigger, and the hammer-lifter, of a sear and a rebounder severally supported on pivots at the rear of the trigger and lifter connection, and with their points at position for respectively engaging the hammer-tumbler, one when the hammer is cocked and the other when the hammer is down, said sear and rebounder being provided with engaging parts, whereby the sear is operated for releasing the hammer by movement of the rebounder, substantially as set forth.

3. In a double-action lock mechanism for the purposes specified, the pivoted rebounder, the pivoted sear actuated by said rebounder, and the sear-spring disposed within a recess at the rear part of the guard, in combination with the trigger having a notch in its rear side for working said rebounder, the hammer-lifter hinged to the rear part of said trigger, the cylinder-operating hand, and the hammer provided with the projection 9 and notch 2, the mainspring, and the trigger-spring, substantially as described.

4. The combination, with the trigger and the hammer having its tumbler provided with the single notch 2, of the pivoted sear and the rebounder having the engaging head, said pivoted sear and rebounder located beneath the hammer in rear of the trigger and severally disposed in relation to each other and to the hammer-tumbler, so that said sear and rebounder each engage successively the single notch on the hammer-tumbler, accordingly as the hammer is at backward or forward position, substantially as and for the purpose set forth.

5. The rebounder having a slot or recess 6 in its top end and the sear-spring arranged through said slot in the rebounder, with one of its ends fixed in the guard and its other end engaging with the sear, in combination with the pivoted sear, the hammer, and the trigger, substantially as set forth.

6. In combination with the frame, the trigger, and the hammer in a revolver, the guard having its rear end fitted to match the cavity in the frame and provided with a recess in its top side, and with lateral pin-holes in the guard and frame that correspond with the rebounder-axis, the rebounder, and sear assembled in said recess in the guard and supported by short pivot-studs, substantially as set forth, whereby said parts can be assembled in the guard before the guard is put into the frame, and together finally secured by a pin driven. through the frame, guard, and rebounder in substitution of the short stud in the rebounder-fulcrum.

7. The combination of the pivoted hammer having the notched tumbler at its lower end, the sear pivotally supported in a recess in the rear end of the guard, having an upwardly-directed end that engages the hammer-tumbler and an extension rearward from its pivoting-axis, the pivoted rebounder having a forwardly-projecting arm furnished with a lug or engaging surface that works in conjunction with said sear for disengaging its point from the notch on the hammer-tumbler, and the trigger having in its rear side a notch in which the arm of the rebounder engages, and whereby the rebounder is operated in both upward and downward direction by the trigger, substantially as set forth.

8. In a fire-arm having a central-stem ejector that is actuated by a gear or finger-disk in the hinging-joint, an intercepting-block for engaging said finger-disk fitted within a recess at the fore end of the frame and supported on the frame by intermatching grooves and ribs r, in combination with the barrel-hinge, finger-disk, and ejector, substantially as set forth.

9. In combination with the ejector, ejector-spring, ejector-stem, and finger-disk having a lug or notch thereon, the notched intercepting-block or catch-piece fitted within a recess at the fore end of the frame, with intermatching ribs and grooves at the sides thereof, and a spring confined within the recess of the frame in rear of said catch-plece and forward of the guard that normally presses said block or catch-piece toward the finger-disk, substantially as set forth.

10. In a fire-arm having a central-stem ejector that is actuated by a gear or finger-disk in the hinging-joint, the intercepting-block fitted within a recess at the fore end of the frame and provided with a notch or lug that engages with and holds: said finger-disk when in normal position, and a locking-lever pivoted in said intercepting-block and engaging the frame to prevent backward movement of the block, in combination with the finger-disk and the barrel-hinge having a shoulder that trips said locking-lever when the barrel is tilted, substantially as set forth.

11. In a fire-arm having a central-stem ejector actuated by a gear or finger-disk in the hinging-joint, an intercepting-block fitted within a recess at the fore end of the frame, provided with a notch or lug that engages with and holds the finger-disk, and a locking-lever thereon that engages the frame to prevent backward movement of said intercepting-block, said locking-lever having a head that fills the opening of the recess in which the intercepting-block moves when said block is in normal position, in combination with the finger-disk, the barrel-hinge, and recessed fore end of the frame, substantially as set forth.

12. The combination, substantially as described, of the frame and barrel-hinge, the peripherally-notched finger-disk, the backwardly and forwardly movable intercepting-block and its advancing-spring fitted within a recess in the fore end of the frame below said finger-disk, the locking-lever pivoted in said block and having the projecting front end, and a head that fits into the end space between the block and frame, and a spring disposed between said locking-lever and block that normally presses said lever-head into said end space, for the purposes set forth.

Witness my hand this 18th day of November, A. D. 1889.

HOMER M. CALDWELL.

Witnesses:

CHAS. H. BURLEIGH,

WM. A. RICHARDSON.