US 445511

UNITED STATES PATENT OFFICE.

HENRY LOVE, OF CREUSOT, FRANCE.

DOUBLE-ACTION REVOLVER.

SPECIFICATION forming part of Letters Patent No. 445,511, dated January 27, 1891.

Application filed September 30, 1890. Serial No, 366,624. (No model.)

To all whom it may concern:

Be it known that I, HENRY LOVE, of Creusot, in the Republic of France, have invented a new useful Improvement in Double-Action Revolvers, which improvement is fully set forth in the following specification.

This invention relates to the lock mechanism of double-action revolvers in which the movement of the trigger under pressure of the finger serves both to raise the hammer to full-cock and also to release the same and discharge the weapon.

In the most common type of self-cocking revolvers the hammer is not set or arrested at full-cock, but is raised and released by a continued pressure upon the trigger. It is difficult to secure accuracy of aim with this kind of a revolver, owing to the fact that the user is not warned of the approach of the point of discharge, and because, also, during all the time of cocking and firing a very strong pull must be exerted upon the trigger so as to overcome the force of the mainspring.

According to the present invention the lock mechanism is so constructed that when the hammer is fully drawn back it is arrested and set by the sear at full-cock, and the trigger is at once relieved of the pressure of the mainspring. The hammer is dropped by a further slight motion of the trigger. Thus the pressure required to drop the hammer is wholly independent of the force of the mainspring, and may be adjusted to that amount which conduces to the most efficient use of the weapon, which amount varies according to the purpose for which the revolver is designed.

I am aware that it is not broadly new to provide a double-action revolver with mechanism enabling it to be set at full-cock by a pull on the trigger and released by a further pull; but the means hereinafter described are believed to accomplish this result in a more efficient and reliable manner than any heretofore devised. In one prior lock mechanism of this type the hammer, when at full-cock, is engaged by a notch in the trigger itself, and consequently bears with its full force on the trigger. In another form heretofore devised the hammer-lifter is thrown out of engagement with the hammer, leaving the latter in firing position as soon as it is set at full-cock, the sear being tripped by contact therewith of a rigid projection of the trigger.

According to the present invention the lifter remains in position to prevent the fall of the hammer until the trigger is pulled for the purpose of discharging the weapon, when the lifter is thrown out of engagement with the hammer. This may be accomplished in various ways. Preferably it is effected through the action of the tripper, which at this moment makes contact with the sear. This tripper, which is carried by the trigger, is not rigidly connected therewith, but is pivoted thereon and pressed in the direction of the sear by a spring.

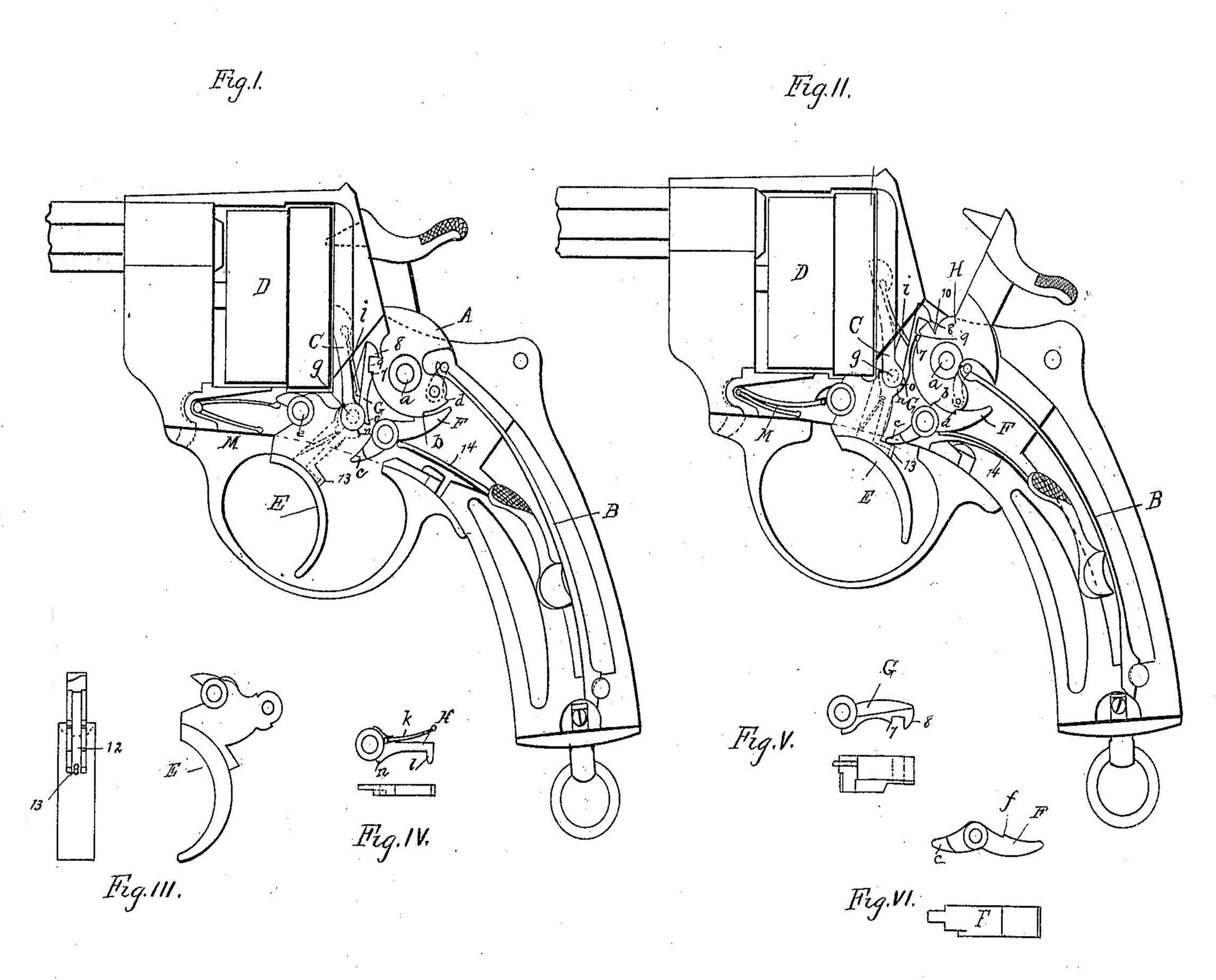

In the accompanying drawings, which form part of this specification, Figure I is a side elevation of the lock mechanism of a double-action revolver equipped with my improvements, the hammer being down. Fig. II is a similar view showing the parts in the position they occupy when the hammer is about to be released by the sear. Fig. III shows the trigger in detail; Fig. IV, the tripper; Fig. V, the lifter, and Fig. VI the sear.

The invention is shown as applied to an ordinary French army revolver. I have, however, applied it to other revolvers—such as the well-known Smith & Wesson—without changing the essential features of the invention. Simple modifications in the shape and arrangement of some of the parts are all that is necessary to effect such application.

A represents the hammer, which is pivoted at a and provided with the usual half-cock point b and full-cock point d.

B is the mainspring; C, the click for rotating the chambered cylinder D; E, the trigger, and F the sear. These parts, except in the particulars hereinafter pointed out, are of ordinary construction.

G is the lifter for cocking the hammer. It is pivoted at g to the trigger E, which is pivoted to the case of the lock mechanism at e. The lifter has two shoulders or catches 7 and 8. The shoulder 7 acts to raise the hammer by engagement with the notch 9, being normally held in contact with the edge of the hammer by the pressure of a light spring 7, which for convenience is in this case carried by the click C. The shoulder 8 normally remains in the notch 10 of the hammer, and prevents return of the trigger so long as the hammer is in a raised position. In these respects the lifter is of known form.

The movable tripper K is pivoted to the trigger on the same pin as the lifter. It is disposed and has a limited play in a mortise 12 in the trigger. (See Fig. III.) It is normally pressed in the direction of the sear by a spring k, which, for a purpose hereinafter explained, is stronger than the lifter-spring 2. The motion of the tripper in this direction is limited by a stop-pin 13. This tripper has the general shape of an L. Its short arm is the part which at the proper moment makes contact with and trips the sear. At its upper end near the center of oscillation is a shoulder n, adapted at the proper time to engage the shoulder o of the lifter G.

The sear F has the usual catch f for engaging the full-cock and half-cock points b and d of the hammer, and is pressed against the latter by the sear-spring 14. On its forward end the sear has a tongue c, which is in the same plane as the tripper and adapted to come in contact therewith, as shown in Fig. II.

The trigger is returned to its normal position after firing by the trigger-spring M.

In operation, the parts being in their normal positions, Fig. I, the user to cock the hammer pulls firmly on the trigger, as in firing. As the trigger is drawn back, the lifter turns the hammer on its center until the catch f in the sear engages the full-cock point or shoulder and retains the hammer at full-cock against the pressure of the mainspring. During this movement the shoulders n and o on the tripper and lifter, respectively, have been approaching each other until finally they come in contact, as shown in Fig. II. At this moment, also, the tongue c of the sear is in contact with the lower end of the tripper. It is to be noted that when the hammer rests at full-cock the catch 7 of the lifter G still prevents the falling of the hammer, even if released by the sear, though the hammer no longer rests on this catch. When now, the parts being in the position shown in Fig. II, a further pull is exerted on the trigger for the purpose of firing, the tripper does not at once trip the sear, because the resistance of the lifter G causes the tripper to retreat farther into the mortise of tho trigger, compressing its spring k until the force of the latter (which, as stated above, is stronger than the lifter-spring) raises the lifter. This takes place before the tripper finally tilts the sear and permits the hammer to fall. As soon as the pressure of the finger upon the trigger is released the trigger-spring M returns the trigger, and with it the lifter and tripper, to the positions shown in Fig. I.

It will be observed that the self-cocking mechanism herein described does not in any way interfere with the setting of the hammer at full-cock or half-cock by hand in the usual way.

I claim as my invention—

1. In a double-action revolver, the combination, with the hammer, the trigger, the

sear, and devices for raising the hammer by the motion of the trigger until caught at full-cock by the sear, of a movable spring-mounted tripper carried by the trigger and disposed in the plane of the sear so as to trip the same upon a further motion of the trigger, substantially as described.

2. The combination of the hammer, the trigger, the lifter carried by the trigger and engaging with the hammer, the sear, and the tripper pivoted to the trigger and adapted to trip the sear by further motion of the trigger after the hammer has been set at full-cock, substantially as described.

3. The combination, with the hammer, trigger, and sear, of the lifter carried by the trigger, and the sear-tripper pivoted to said trigger and adapted to move the lifter out of engagement with the hammer before tripping the sear, substantially as described.

4. The combination, with the hammer, trigger, and sear, of the lifter and its spring, the tripper pivoted on the trigger, and the tripper-spring arranged to press the tripper toward said sear and lifter when the hammer is cocked, said spring having greater strength than the lifter-spring, the tripper being arranged to come in contact with the lifter and hold it away from the hammer before tripping the sear, substantially as described.

In testimony whereof I have signed this specification in the presence of two subscribing witnesses.

HENRY LOVE.

Witnesses:

LOMBARD GERI,

L. DE TASENT.