US 273644

UNITED STATES PATENT OFFICE.

JACQUES E. TURBIAUX, OF PARIS, FRANCE.

REVOLVER.

SPECIFICATION forming part of Letters Patent No. 273,644, dated March 6, 1883.

Application filed June 29, 1882. (No model.) Patented in France June 9, 1882, No. 149,466; in Belgium June 9, 1882, No. 58,148; in England June 10, 1882, No. 2,731, and in Italy June 14, 1882, Nos. 14,318 and 346.

To all whom it may concern:

Be it known that I, JACQUES EDMOND TURBIAUX, a citizen of the Republic of France, residing at Paris, have invented certain new and useful Improvements in Fire-Arms; and I do hereby declare the following to be a full, clear, and exact description of the invention, such as will enable others skilled in the art to which it appertains to make and use the same, reference being had to the accompanying drawings, and to letters or figures of reference marked thereon, Which form a part of this specification.

That class of revolvers known as “pocket-revolvers” as heretofore constructed embody features that possess disadvantages. First, generally they are comparatively heavy as well as bulky, and not conveniently carried, and if made small enough to obviate these inconveniences then they carry but a very limited number of cartridges.

My invention has a twofold object—namely, to obviate the above enumerated disadvantages and to adapt the weapon for use as a defensive one after the ammunition thereof has been exhausted; and it consists, first, in a revolver without a stock or handle, adapted to be held in the clenched hand between the fingers and palm, the barrel projecting from between two of the fingers; second, in a revolver without a stock or handle, constructed to be held in the clenched hand, the barrel projecting from between two of the fingers, and to be fired by alternately moving the fingers toward and from the palm of the hand; third, in a revolver, the combination, with the barrel, of a flat, cylindrical, or oval chamber containing the operative parts of the revolver, and adapted for use as a stock or handle; fourth, in a revolver, the combination, with the barrel, of a flat, cylindrical, or oval chamber containing the operative parts of the revolver, and provided with bearings for the fingers when held between them and the palm of the hand, and adapted to be fired by alternately moving the fingers toward and from the palm of the hand; fifth, in a revolver in which the cartridge-magazine, the mechanism for moving the magazine, and the firing mechanism are all located within the same chamber; sixth, in a revolver in which the cartridge-magazine consists of a ring provided with a series of radially-arranged cartridge-chambers, in combination with a hammer or firing-pin located and operating within the ring-magazine; seventh, in a revolver, a ring-shaped cartridge-magazine having the form of a truncated cone, in which are formed a series of radially-arranged cartridge-chambers; and, lastly, the invention consists in certain details of construction, all as hereinafter fully described, and shown in the accompanying drawings, in which—

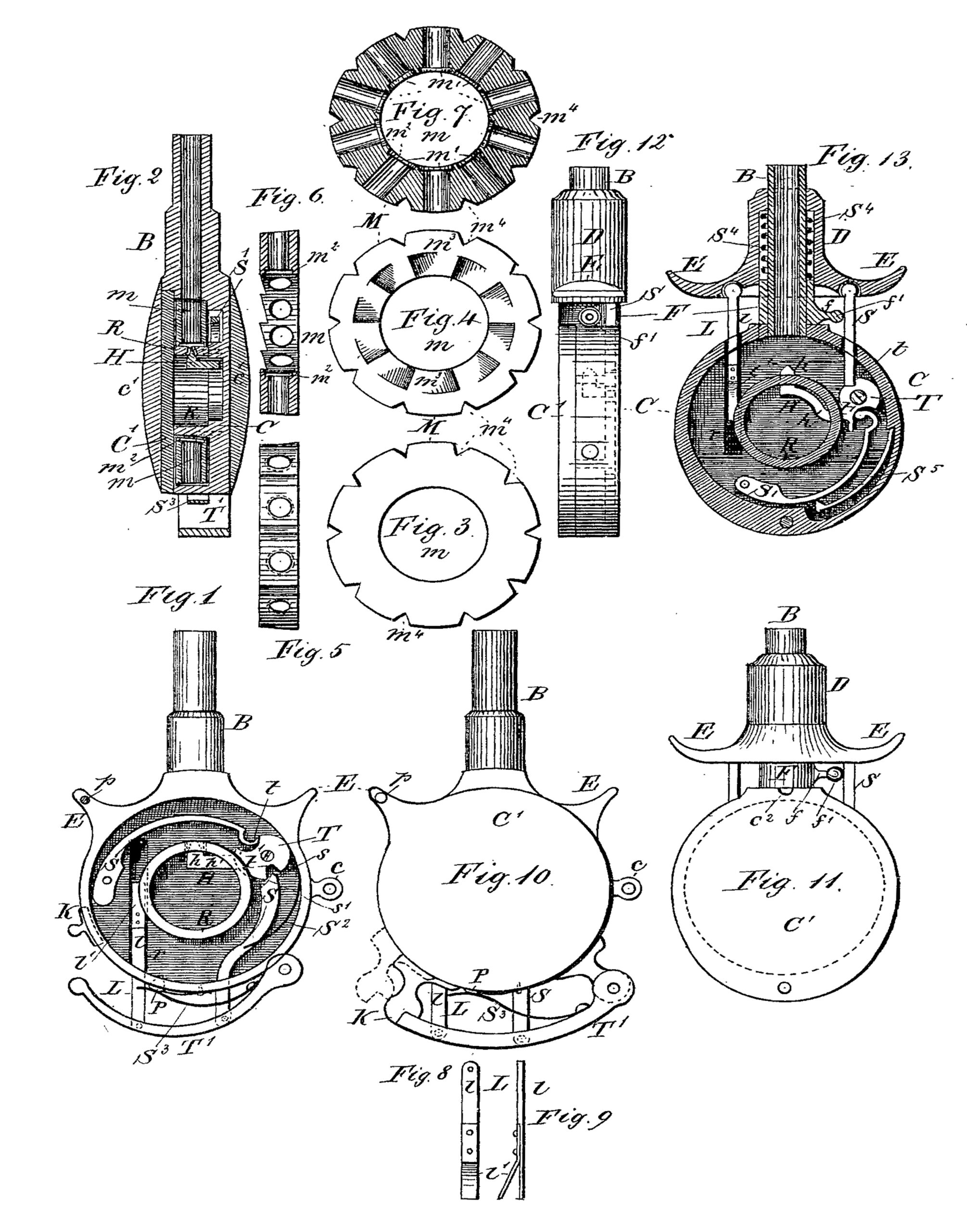

Figure 1 is an elevation of a revolver constructed according to my invention, the slide or cover, as well as the cartridge-magazine, being removed to show the firing and cartridge-magazine-feeding mechanism. Fig. 2 is a vertical transverse section of the same, showing the slide or cover and cartridge-magazine in position. Figs. 3, 4, 5, 6, and 7 show the cartridge-magazine by a top and bottom plan view, by an edge view or elevation, and: by a vertical and horizontal transverse section, respectively. Figs. 8 and 9 are face and edge views, respectively, of the spring-rod for revolving the cartridge-magazine. Figs.10 and 11 show in front elevation a slight modification of construction of the revolver; and Figs. 12 and 13 are a side elevation and a vertical transverse section of Fig. 11.

In these drawings like letters of reference are employed to indicate like parts wherever such may occur.

C indicates a flat casing of any suitable metal, and either of cylindrical or oval form, and of such a thickness as to contain the operating mechanism of the revolver, as well as the cartridge-magazine. To this casing is screwed the barrel B, which may be a smoothbore or a rifled barrel, preferably the latter; or said barrel may form an integral part of the casing—that is to say, the said casing and the barrel may be of one piece, and either of steel or other suitable metal. The casing has two outwardly-curving ears or projections, E, projecting in opposite directions from its periphery and on opposite sides of the barrel B, said ears serving as bearings for the fingers, the palm of the hand serving as a bearing for the casing when the revolver is being used. The dimensions of the casing C must therefore be such as to be conveniently held within the hand, with the fingers closed over the projections or ears E;, the barrel B projecting from between two of the fingers—namely, the two middle fingers. Its dimensions, therefore, are such as to adapt the revolver to be carried in the vest-pocket, and to that end I connect with or form-on the periphery of said casing a loop, c, to attach the revolver to a watch chain or guard, as it does not occupy much more space than an ordinary gentleman’s double-case watch, and the general form of the casing C is approximately that of such a watch.

The barrel B, I prefer to make of such a length as to not only clear the fingers sufficiently to permit the necessary reciprocating motion thereof toward and from the palm of the hand for discharging the revolver, but also to adapt the revolver for use as a defensive weapon after the charges in fits magazine have been exhausted. It will be readily understood that a revolver capable of being held in the hand as described, with its barrel projecting some distance between two of the fingers, becomes an effective defensive weapon, whereby very severe, if not fatal, blows may be dealt, while the hold upon the weapon is such as to preclude all possibility of its being wrenched from the hand. Herein this improved revolver becomes a defensive arm even when its ammunition is exhausted.

Centrally of the casing C is located a ring, R, perforated on a line with the axis of the barrel B for the reception and passage of the nose or firing point or pin of the hammer H. This ring serves a twofold purpose—namely, as a breech-block for the magazine M and as a pivot upon which said magazine rotates, as hereinafter more fully described.

The hammer H and the tumbler T are made of one piece of metal, and the firing piece or nose h consists of a cone formed at right angles to the arm h’ of said hammer, and lies within the perforation of the ring R, and is constructed for center-fire cartridges, though it is evident that by a slight alteration in form, such as any one acquainted with the construction of percussion fire-arms would be enabled to give it, the said hammer may be constructed for rim-fire cartridges. The tumbler T has a notch, t, on one side, within which lies the end of the mainspring S’, the other end of which is attached within the casing C, as shown. It has also another notch, t’, on its opposite side, with which engages the sear S for retracting the hammer.

The sear in this construction of revolver consists of a lever pivoted to a trigger, T’, which is itself pivoted upon the periphery of the casing O, a suitable opening being provided in said periphery for the passage of said lever. The outer end of the sear S has an inclined face or nose, s, and a concave face, s’. When the trigger T’ is moved inwardly toward the periphery of the casing the lever or sear S engages the notch t’ of the tumbler and tilts the latter and the hammer backward. This backward movement of the tumbler depresses the end of the spring S’ and increases its tension. When the trigger has, however, reached or is about to reach the limit of its inward movement the nose s thereof leaves the notch t’, and the tumbler is then free to be acted upon by the mainspring S’, which throws said tumbler and hammer forward to explode a cartridge.

S2 is the sear-spring, the function of which is, as in other fire-arms, to carry the sear back into its normal position as soon as the pressure upon the trigger is removed.

M is the magazine. It consists of a disk of metal having a central aperture, m, of such a size as to adapt it to be fitted onto the annular breech-block R. It is provided with a series of radial chambers, m’, for the reception of a corresponding series of cartridges that are inserted into said chambers through the central aperture, each chamber having its rear end enlarged sufficiently to receive the flange of the cartridges, as shown at m2, Figs. 2, 4, 6, and 7. Upon one of the faces of the magazine are formed notches m3, decreasing in depth and forming a series of teeth equal in number to the number of cartridge-chambers, of which I have shown ten. These teeth m3 serve to rotate the annular magazine upon its annular breechblock pivot by means of a spring-lever, L, composed of the rigid or lever portion l, and the spring l’, as plainly shown in Figs. 8 and 9. This actuating-lever is also pivoted to the trigger T’, and passes through a suitable opening in the periphery of the casing C, and said lever lies within a recess, r, formed in the bottom of the casing C, as shown in Figs. 1 and 13, in such manner that the spring l’ thereof will project slightly above the edges of the recess, and enable it to engage the teeth m3 of the magazine. These teeth are so located with respect to the cartridge-chambers that at each inward movement of trigger T’ the magazine will be rotated a distance equal to that between two of its cartridge-chambers to bring a fresh cartridge on a line with the bore of the barrel. Inasmuch as the actuating-lever may not always move the magazine the. required distance, and also to lock said magazine into position for firing, I employ a conical spring stud or pin, P, that passes through a perforation in the periphery of the casing C, and projects into V-shaped notches m4, formed in the periphery of the magazine M. The form of the notches and the corresponding form of the stud enable the latter to move out of the former with comparative ease as the magazine is revolved. Said pin is, however, held within its notch at the moment the sear releases the tumbler, because at that moment the trigger has reached the limit of its inward movement and lies upon the stud P, upon which also bears the trigger-spring, as shown. The cartridge-magazine may have its inner and outer peripheries perfectly cylindrical and conform in this respect to the form of the breech-block R and the inner periphery of the casing. It is obvious, however, that the removal of the magazine from the casing would become difficult with such a construction, inasmuch as it is necessary that these parts should be fitted snugly together. To obviate this difficulty I form the inner periphery of the casing, the inner and outer peripheries of the magazine, and the outer periphery of the annular breech-block tapering outward, so that said magazine will fit snugly in its place, yet will, by reason of its having the form of a truncated cone, fall out of the casing on opening the lid thereof and turning said casing over.

S3 is the trigger-spring, the function of which is to bring the said trigger back into its normal position after the firing of each cartridge.

C’ is the lid or cover of the casing C, which may be arranged to swing upon a pivot, p, formed on or attached to one of the curved projections or finger-bearings E, as shown in Figs. 1 and 11; or said lid may be hinged or screwed to the casing C, or connected therewith by a bayonet-joint, or attached thereto in any other manner to render its removal convenient for reloading the magazine or inspecting the operative mechanism of the revolver.

The casing may be engraved or otherwise ornamented and plated with any of the metals usually employed. I prefer, however, in order to impart to it the best shape for securely holding it within the closed band, to either make both of its faces convex or attach thereto convex facing-sections c’, of any desired precious metal, or of wood, ivory, or other preferred or desired material.

As hereinbefore stated, a revolver devoid of the usual stock or handle, and in which the firing mechanism, the magazine, and the magazine-feeding mechanism are contained within the same chamber, said chamber serving as a stock or handle, and means to actuate the firing or magazine-feeding mechanism by the alternate movement of the fingers toward and from the palm of the hand, comprehends my invention. It is obvious, however, that the construction and relative arrangement of these elements may be varied without departing from the peculiar nature of this invention. For instance, the trigger T’, which is of the same width as the periphery of the casing C and of corresponding form, is, as shown in Fig. 1, pivoted eccentrically. This is not absolutely necessary, as it may be arranged concentrically with the casing, as shown in Fig. 10; or the said trigger may be dispensed with entirely and the curved finger-bearings may be made to act as a trigger, as shown in Figs. 11, 12, and 13. In this case, instead of forming the bearings E on the casing or chamber C, I form them upon a sleeve, D, that is fitted upon the barrel B, and a second shorter sleeve, F, at the base of the barrel.

Within the sleeve D and between its upper inner end and between the outer edge of the sleeve F is located a spring, S4, coiled around the barrel B.

To the under concave side of the sleeve D are pivoted the sear S and lever L, the location of the mainspring and the form of the tumbler being altered to suit the altered circumstances, yet these alterations are only such as would readily suggest themselves to any intelligent mechanic conversant with this branch of the arts.

To prevent the accidental discharge of the weapon, I provide, as shown in Figs. 1 and 10, a sliding locking-stud, K, against which the trigger may abut, or to which said trigger may be locked at what I may term “half-cock,” as shown in Figs. 1 and 10.

As shown in Figs. 11, 12, and 13, the sleeve F has an arm, f, terminating in a button, f’, and the casing C has a notch, c2, for the reception of said arm f, Fig. 11. The upper face of the casing C, upon which the sleeve F rests and rotates, may be or is slightly inclined from the notch c2, at which it has its greatest depression. Thus, when the sleeve is rotated until its arm f lies within the notch, the weapon is ready for firing, as the arm and its button will be out of the path of the finger-bearings on sleeve D; but when said sleeve F is turned to bring its arm and button in line with the finger-bearings E, then the sleeve D cannot be depressed sufficiently to move the sear out of contact with the tumbler, so as to permit the mainspring to throw the hammer forward and explode the cartridge.

As will be seen by Fig. 13, in this construction there is no “trigger,” properly so called, and but three springs are employed—namely, the coiled spring S4, the mainspring S’, and an auxiliary spring, S5, for maintaining said mainspring in proper relation with the tumbler and lock the cartridge-magazine in position.

From the detailed description above given it is thought to be unnecessary to describe the operation of the fire-arm, as any one acquainted with such will readily understand the same.

Having vow described my invention, what I claim, and desire to secure by Letters Patent, is—

1. In a fire-arm of the class described, the combination, with a barrel, a casing adapted to be held as described, a cartridge-magazine, and a hammer located within said casing, of two levers arranged to operate the cartridge magazine and hammer, respectively, by the alternate movement of the fingers toward and from the palm of the hand, as described.

2. In a fire-arm of the class described, the combination of a barrel, a casing constructed to serve as a handle for the arm and provided with bearings E, a cartridge-magazine and hammer located within said casing, of two levers for actuating the hammer and cartridge-magazine, respectively, by alternate movement of the fingers toward and from the palm of the hand when the same is held as described, substantially as and for the purpose specified.

3. In a fire-arm of the class described, a barrel and casing adapted to be held as described, a cartridge-magazine and hammer contained within said casing, in combination with a lever for actuating the hammer and a lever for actuating the cartridge-magazine, and a locking-pin to lock said magazine in position for firing by the alternate movement of the fingers toward and from the palm of the hand, substantially as described.

4. In a revolver, an annular breech-block and cartridge-magazine revolving upon said breech-block, a hammer located within and moving through the latter, a tumbler and mainspring for said hammer, appliances for operating said tumbler and cartridge-magazine, in combination with a casing constructed to be held between the fingers and palm of the hand, and having a single chamber in which the above mechanism is contained, a barrel connected with said casing, and mechanism whereby the firing and magazine-moving devices may be operated by the alternate movement of the fingers toward and from the palm of the hand, as set forth.

5. In a fire-arm of the class described, a casing of cylindrical form, containing the operating mechanism, in combination with a removable lid and a suspension-loop, substantially as described, for the purpose specified.

6. In a fire-arm of the class described, the combination, with the casing C, barrel B, an annular breech-block and cartridge-magazine, and a hammer, of bearings E and two levers connected thereto for operating the cartridge-magazine and hammer by the pressure exerted upon said bearings E when the arm is held as described, all combined and co-operating substantially as and for the purpose specified.

7. In a revolver, an annular casing provided with a removable lid and an annular breechblock having their inner and outer peripheries respectively inclined or beveled, in combination with an annular cartridge-magazine having its inner and outer peripheries correspondingly inclined or beveled, substantially as and for the purposes set forth.

8. In a revolver of the class described, the annular cartridge-magazine provided with V-shaped peripheral notches and having the form of a truncated cone, and a series of cartridge-chambers radiating from its inner to its outer periphery, in combination with an annular breech-block having the form of a truncated cone also, the casing C, having its inner periphery beveled, as described, of the locking-pin P and the trigger T’, all arranged for co-operation substantially as and for the purposes specified.

9. In a fire-arm of the class described, a barrel, an annular casing, a cartridge-magazine and hammer, and a locking dog or pin for locking the cartridge-magazine into position for firing, in combination with a trigger and two levers for actuating the cartridge-magazine and hammer when said trigger is operated by the movement of the fingers toward and from the palm of the hand, substantially as described.

10. The combination of the barrel B, casing C, provided with bearings E, and a trigger, T’, with the breech-block R, magazine M, having notches m3, and the levers L S, connected with said trigger, said parts being arranged for co-operation substantially as described, and for the purposes set forth.

In testimony whereof I hereto affix my signature in presence of two witnesses.

JACQUES EDMOND TURBIAUX.

Witnesses:

E. P. MACLEAN,

E. PAGE.