US 308231

UNITED STATES PATENT OFFICE.

JAMEST. ALDRICH, OF NORWICH, CONNECTICUT.

DOUBLE-ACTING REVOLVER.

SPECIFICATION forming part of Letters Patent No. 308,231, dated November 18, 1884.

Application filed January 26, 1884. (No model.)

To all, whom, it may concern:

Be it known that I, James T. Aldrich, of Norwich, in the county of New London, and in the State of Connecticut, have invented certain new and useful Improvements in Double-Acting Revolvers; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings, in which—

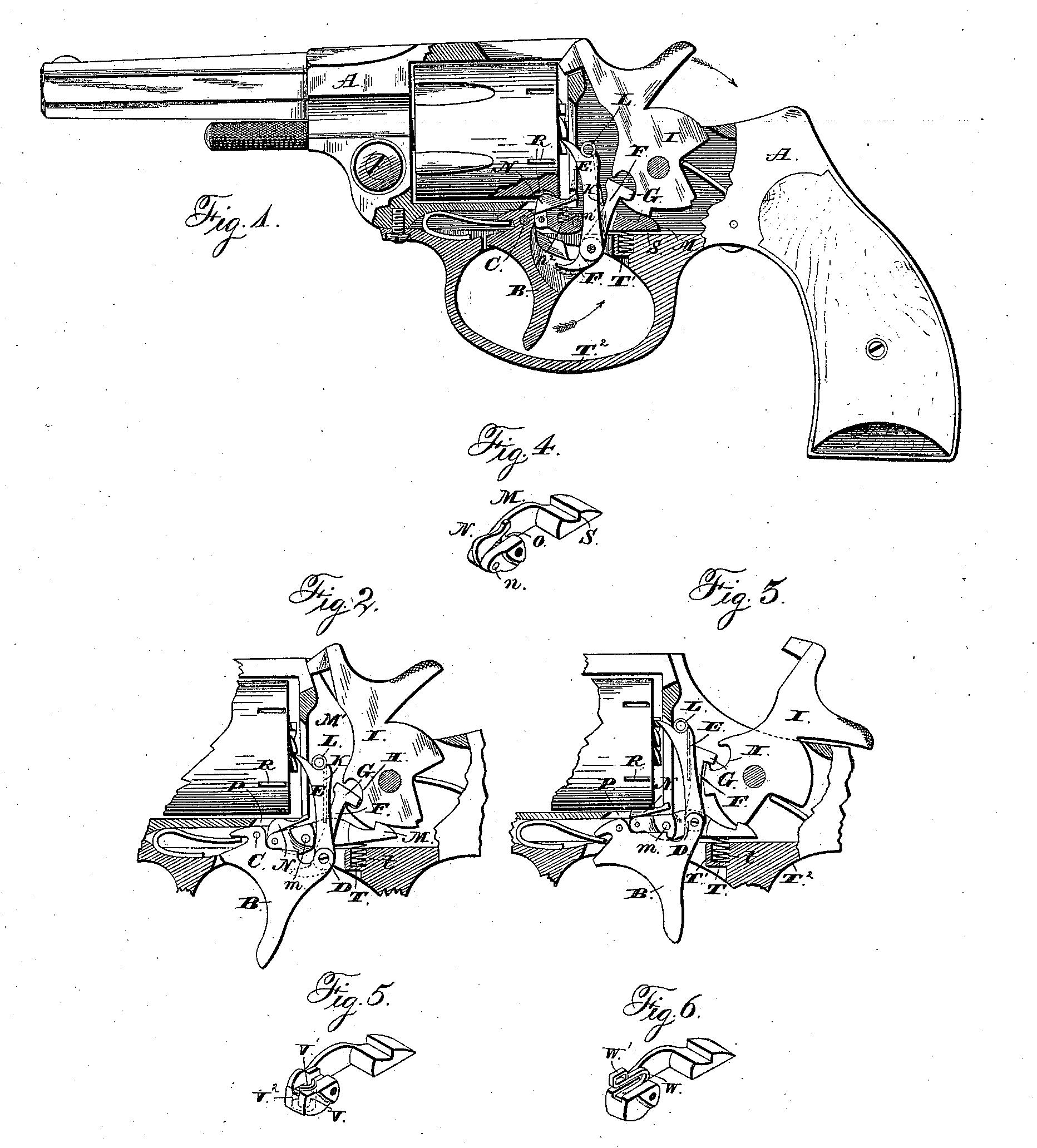

Figure 1 shows a view in side elevation of a double-acting pistol provided with my combined sear and stop, a portion of the frame being broken away to show the parts clearly; Fig.2, a similar view of the lock portion of the pistol, showing the position of the parts when the hammer is at half-cock; Fig. 3, a similar view showing the parts in the position which they have when the hammer is at full-cock released and about to fall; Fig. 4, a detail view of the sear and stop, and Figs. 5 and 6 similar views of modifications of the same.

The object of my invention is to provide an improved combined Sear and stop for double-acting pistols; and to this end it consists in the construction, arrangement, and combination of parts, as hereinafter set forth, and more particularly pointed out in the claims.

In the drawings, A represents the main or stock portion of a double-acting pistol. As shown, the pistol is provided, as usual, with the trigger B, pivoted at C, and having pivoted between upwardly-projecting ears D at its rear side the lower ends of the cylinder-turning pawl or hand E. and the cocking-pawl F. The latter has a rearward projection, G, adapted to enter and engage the recess or notch, H, in the front side of the hammer-cam I. The cocking-pawl is forced backward so that the projection G is normally in the notch in the can by the spring-arm K, extending from the end of the spiral spring L on the side of the cylinder-turning hand. Thus the spring serves to separate the upper ends of the two pawls and presses the one forward and the other backward, so that each shall perform its respective work properly. The action and form of these parts I need not describe more fully, as I do not claim the same herein.

The combined sear and stop which I have invented is shown at M as a lever pivoted in the frame at n about on a line with the face of the recoil-plate M’. The front end of this lever, which extends forward under the cylinder, carries on its upper face the yielding stop or pawl N, pivoted at n, and normally, forced upward by a spring, n’, in a recess, n^2, in the lever. As shown in Fig. 4, this stop or pawl is pivoted in the front end of a groove, O, in the upper face of the lever, so that when said stop or pawl is depressed it sets down into the groove, as indicated in Fig. 3. The longitudinally-rounded upper portion of the pawl extends up through an opening or slot, P, in the frame into the cylinder-opening, so that it can engage and rise into the stop-notches R R in the cylinder-face. The other or sear end of the lever extends rearward under the hammer-cam, so that the projection S thereon bears against the face of the calm and engages successively the half and full, cock notches therein. This end of the lever is pressed up against the cam-face by the spiral spring T, set in a suitable recess, t, in the upper face of the part T’ of the trigger-guard T^2. As shown, this spring bears against the under face of the sear.

I do not intend to limit myself herein to any particular point of pivoting my combined sear and stop. If desired, it may be pivoted just in front of the hammer and extend out through a suitable slot in the recoil-plate to engage notches in the rear of the cylinder.

If the hammer is raised to full-cock, the sear, as usual, will engage successively the half and full cock notches in the hammer-cam and hold the hammer up. This it will do until the trigger is pulled far enough back to bring the portion N. thereof in contact with the lower face of the front end of the lever. This will then raise that end, as shown in Fig. 3, and so lower the other, and so disengage the projection of the sear from the notch in the hammer-cam to allow the hammer to descend under the stress of the mainspring to fire the cartridge.

The half-cock notch is, as shown, made quite deep, so that when the hammer is drawn back to half-cock the rear end of the lever will be thrown upward by spring T far enough to carry the pawl or stop N on the other end of the lever down out of engagement with the stop-notch in the cylinder, as shown in Fig. 2. The cylinder is then free to be turned by the turning hand or pawl E, which engages the usual ratchet-teeth on the rear end of the cylinder for that purpose. As the hammer is raised still further the projection of the sear passes out of the notch, and is engaged and pressed down by the raised portion or part of the can of greater eccentricity beyond the notch. The other end of the lever is thereby raised, and the pawl or stop N is pressed up against the cylinder-face. By such pressure Said pawl or stop is caused to set down into the groove in the lever and compress its spring n. When, then, the cylinder is turned far enough to bring another stop-notch over the pawl, the latter will fly up into the said notch and lock the cylinder.

The full-cock notch is not deep enough to allow the sear end of the lever to be raised far enough to disengage the pawl from the cylinder-notch, so that when the hammer is at full-cock the cylinder will still be safely locked.

As the locking-stop is, as described, a yielding and not a rigid one, the front end of the lever can be raised by the action of the trigger, as hereinbefore described, far enough to disengage the sear from the full-cock notch to allow the hammer to fall, while the stop still remains in the notch, yielding as the end of the lever carrying it is raised.

In Fig. 5 is shown a modification of the spring locking pawl or stop already described and shown. In this case the pawl, instead of being pivoted, is a vertically sliding or reciprocating one. Its shank V extends down through the end of the lever, and on the lower side it is preferably formed with a head or enlargement to limit its upward movement under stress of the spiral spring V’ in the recess V^2 surrounding shank V.

In Fig. 6 is shown another modified form of stop. In this case said stop is formed of a piece of spring-wire, W, bent as shown. Its upper end, W’, enters and engages the stop-notches in the cylinder in the same manner as the pawls or stops already described.

Having thus described my invention, what I claim is—

1. In combination with the notched cylinder, the pivoted sear carrying a stop adapted to engage the notches on the cylinder, the hammer-cam adapted to press down the engaging end of the sear to cause the stop to enter one of the stop-notches to properly lock the cylinder, substantially as and for the purpose described.

2. In combination with the pivoted sear, carrying at or near its forward end the yielding pawl or stop for entering the cylinder stop-notches, the hammer-cam, adapted by its shape to press down the engaging end of the sear before and after the cylinder has started to revolve, to bring the pawl or stop up against the cylinder in position to engage one of the notches therein, substantially as shown and described.

3. The combined sear and cylinder stop, which consists of the pivoted lever provided at one end with the projection for engaging the notches in the hammer-cam, and at the other with a yielding pawl or stop for engaging the stop-notches in the cylinder, substantially as and for the purpose set forth.

4. A lever carrying at one end a spring-pawl or stop for engaging the stop-notches in the cylinder, and at the other a projection, a notched hammer-cam engaged by such projection, and so shaped as to force the engaging end of the lever in such direction as to bring the yielding stop on the other end thereof into position to engage the cylinder stop-notches, and a spring adapted to press the projection-carrying end of the lever against the cam-face, all combined substantially as and for the purpose described.

5. The pivoted sear provided with a yielding stop or pawl adapted to engage the cylinder stop-notches, and a spring pressing the sear into engagement with the hammer-cam face to cause it to engage the notches therein, in combination with the trigger adapted to actuate. the seal to cause it to disengage the hammer-calm to allow the hammer to fall, substantially as shown and described.

6. In combination with the lever carrying on one end a spring stop or pawl for engaging the cylinder stop-notches and on the other a projection to engage the hammer calm, a spring pressing the latter end to bring the projection thereon against the cam-face, the hammer-cam so formed as to normally keep the engaging end of the lever down, so that the stop on the other end will be in position to engage the cylinder-notches, and provided with a half-cock notch deep enough to allow the lever to be moved by the spring to disengage the stop from the cylinder-notch, substantially as and for the purpose described.

In testimony that I claim the foregoing I have hereunto set my hand this 18th day of January, A. D. 1884.

JAMES T. ADRICH.

Witnesses:

S. E. Gailey,

Hez Perkins.