US 51327

UNITED STATES PATENT OFFICE.

SAMUEL P. LEGG, OF SPRINGFIELD, MASSACHUSETTS.

DIE FOR FORGING AND SHAPING PISTOL-FRAMES.

Specification forming part of Letters Patent No. 51,327, dated December 5, 1865.

To all whom it may concern:

Be it known that I, SAMUEL P. LEGG, of Springfield, Hampden county, Commonwealth of Massachusetts, have invented an Improved Process of Forging Pistol-Frames; and I do hereby declare that the following is a full and exact description thereof, reference being had to the accompanying drawings, and to letters of reference marked thereon.

This invention consists in the arrangement of two sets of dies in such a manner as to allow the frame to be forged at one heat and with only two drops, thus saving fuel and stock and dispensing with a large part of the machinery ordinarily required.

In order to explain this improvement fully it will be necessary to first describe the former process of manufacture as used on the Smith & Wesson pistol-frame, to which this description particularly applies.

In this process are seven heats, as follows: At the first heat the bar of iron was placed under a drop and the front end formed and trimmed off. At the second heat the bar thus formed was placed under a trip-hammer and the handle formed. At the third heat the bar was placed in a vise and the curve given to the handle by bending it. At the fourth heat the general form of the frame was given it in a drop by means of dies. At the fifth heat the ends were squared. At the sixth heat the front end was punched out, as shown at a, Figure 8, in the drawings. At the seventh heat the balls b b, on each side of the frame, were formed by hand.

As each one of these operations consumed a large amount of time, and nearly every step required a separate drop, either a large number of costly drops and fires must be used or the dies must be changed frequently. In the shortest operation—that of drawing out the handle under a hammer at the second heat—it required three men three days to get a thousand through this operation alone, and as there are six other longer operations to go through the process was necessarily a long one, requiring either a large number of men and great expense for machinery, fires, &c., or else weeks to get through all the heats with only one or two drops and fires, as the dies must be changed at nearly every heat.

Now, my invention consists in altering and newly arranging these operations or similar ones and combining them in two pairs of dies, so that at one and the same heat the whole process of forging may be performed, thus saving stock, time, and fuel.

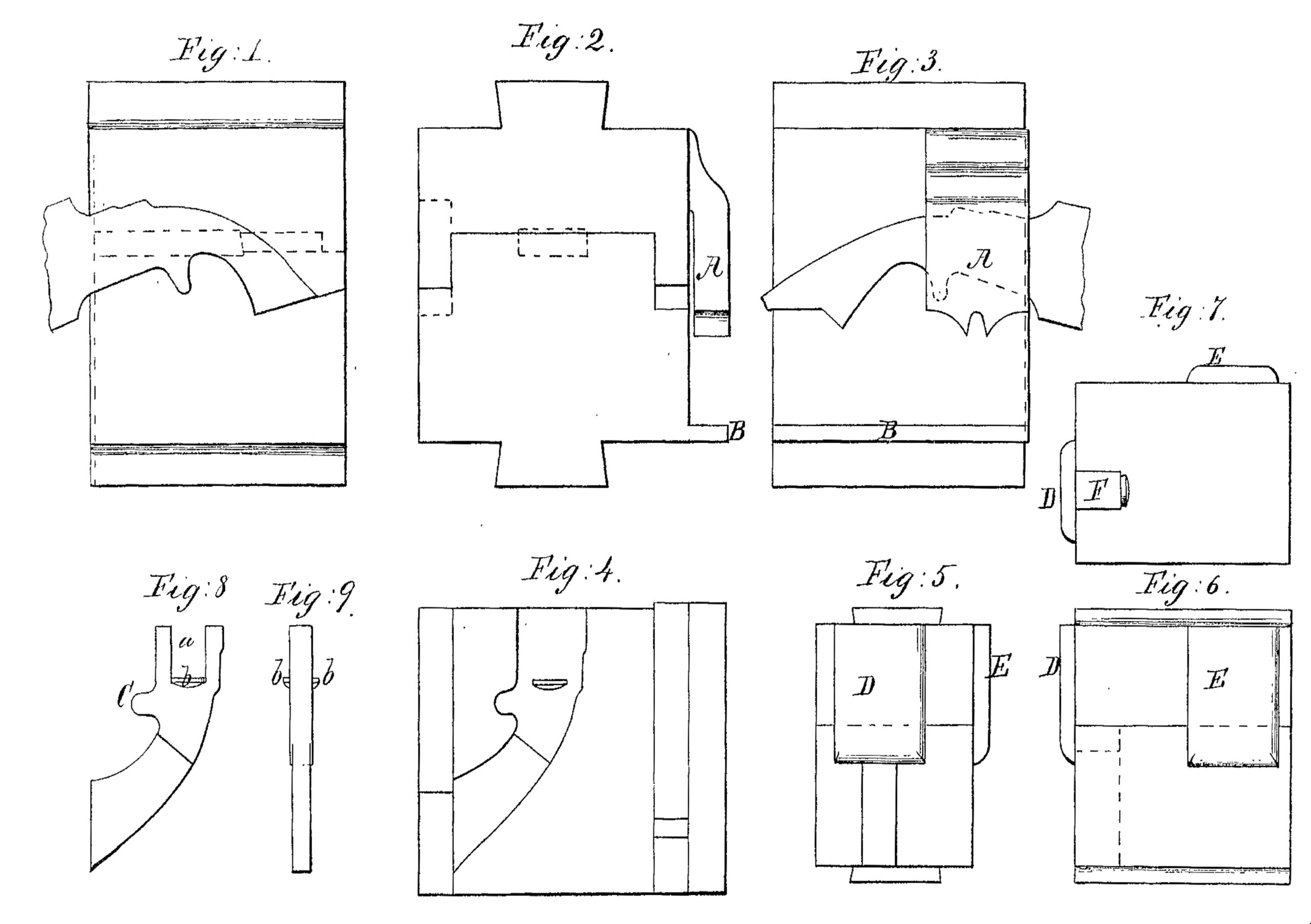

In the drawings, Fig. 1 is a side view of the first pair of dies; Fig. 2, an end view, and Fig. 3 an opposite-side view, of the same. Fig. 4 is a face view of the lower die of this pair. Fig. 5 is an end view, and Fig. 6 a side view, of the second pair; and Fig. 7 is a face view of the top die of the second pair. Fig. 8 is a side view, and Fig. 9 an edge view, of the frame after forging.

In my arrangement all the operations necessary to form the frame, except punching the slot in the front end at a and squaring the ends, are done with the first pair of dies, and these remaining operations are done with the second pair of dies at the same heat. These operations are as follows: The projection C is formed between the part A of the upper die and the part B of the lower die of the first pair. The form of the frame is then partially given to the bar between the two other dies on the same side, as shown in Fig.3. It is then further formed on the other side of the blocks, as shown in Fig. 1. It is then placed between the blocks and, the forming finished, and the balls b b raised by the center dies. It is then taken to the second pair of dies and the slot a in the front end of the frame punched by the part F, and the ends squared by the cutters D E at one blow of the drop.

The great economy of this arrangement and the large saving resulting are evident, as two drops do the work of a much larger number, or of the same number, for a much longer time, and by this arrangement, instead of requiring weeks to forge a thousand frames, two men can forge by this process two hundred and thirty per day complete, or one thousand in a little over four days, and the enormous saving in fuel can readily be seen, as I save the fuel necessary to raise the iron to the proper temperature for forging six times, and also I save largely in stock, for at every heat a scale is formed on the surface of the iron which greatly decreases its bulk, and I save the iron wasted ordinarily in heating six times, amounting to nearly (25) twenty-five per cent of the whole amount.

In this description I have confined myself to the Smith & Wesson pistol-frame, but this invention applies to any pistol-frame sufficiently like it to be forged in substantially the same manner.

Now, having described my invention, what I claim as new, and desire to secure by Letters Patent, is—

The dies constructed as herein described, and for the purpose specified.

SAMUEL P. LEGG

Witnesses:

J. B. GARDINER,

J. E. McINTIRE.