US 183389

UNITED STATES PATENT OFFICE.

FRANK W. FREUND, OF CHEYENNE, WYOMING TERRITORY.

IMPROVEMENT IN REVOLVING FIRE-ARMS.

Specification forming part of Letters Patent No. 183,389, dated October 17, 1876, application filed September 27, 1785.

To all whom it may concern:

Be it known that, I, Frank W. Freund, of Cheyenne, in the county of Laramie and Territory of Wyoming, have invented certain new and useful improvements in Fire-Arms; and I do hereby declare that the following is a full, clear, and exact description thereof, reference being had to the accompanying drawings, making part of this specification, in which—

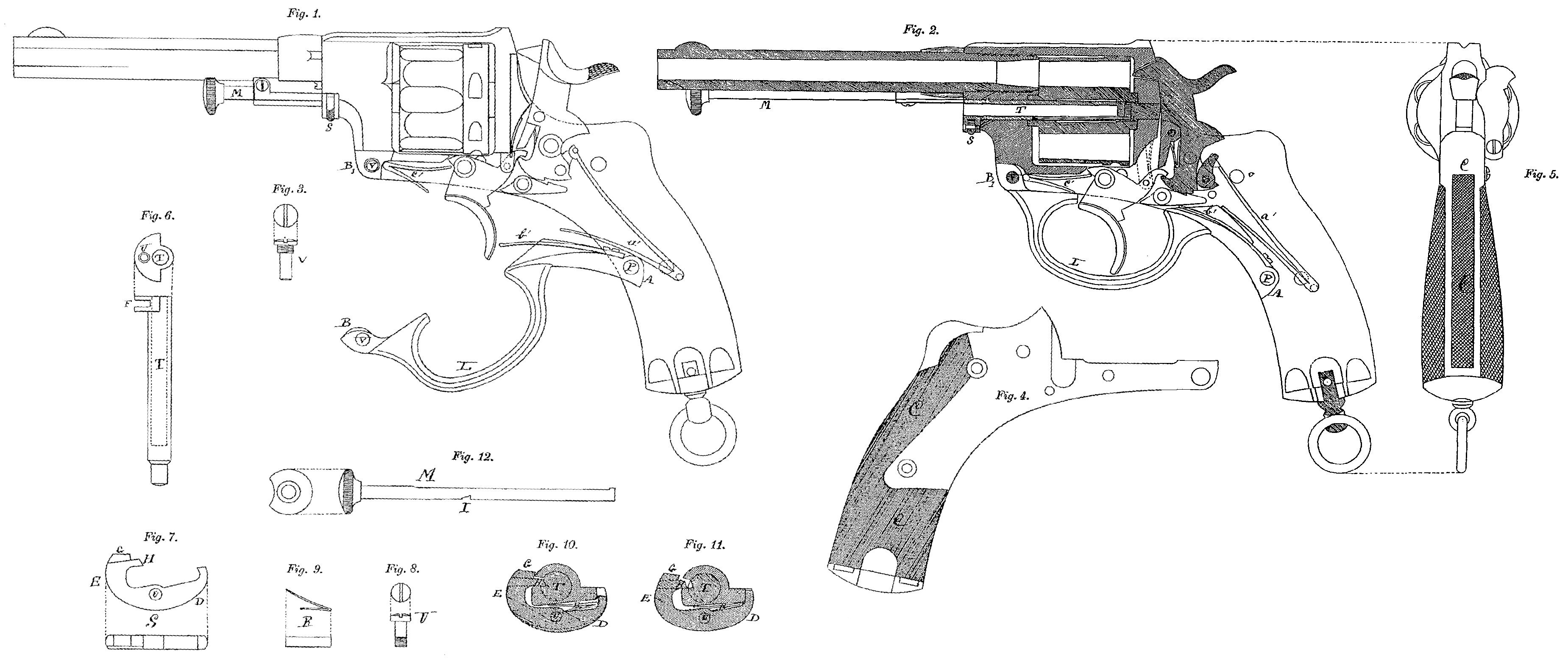

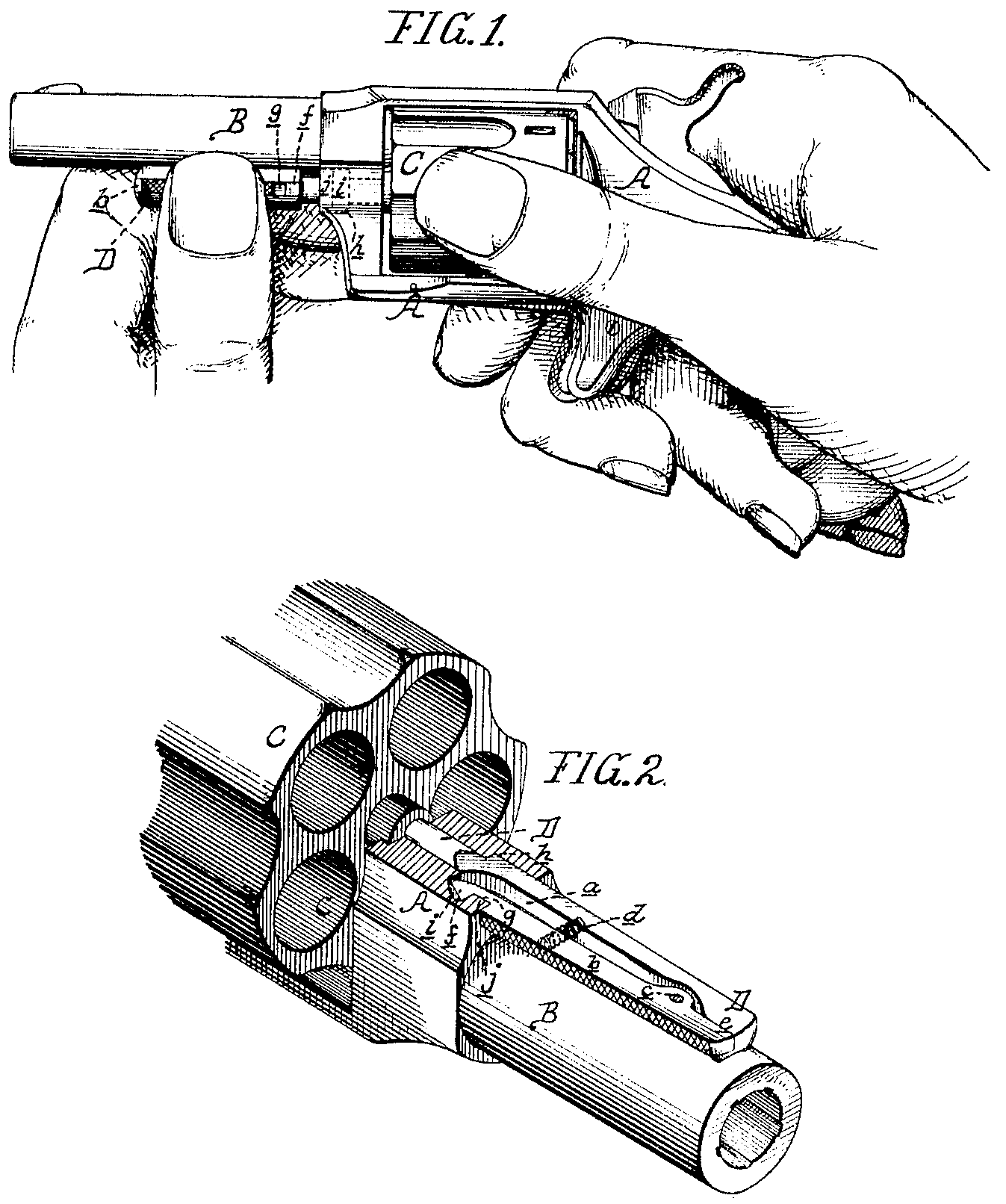

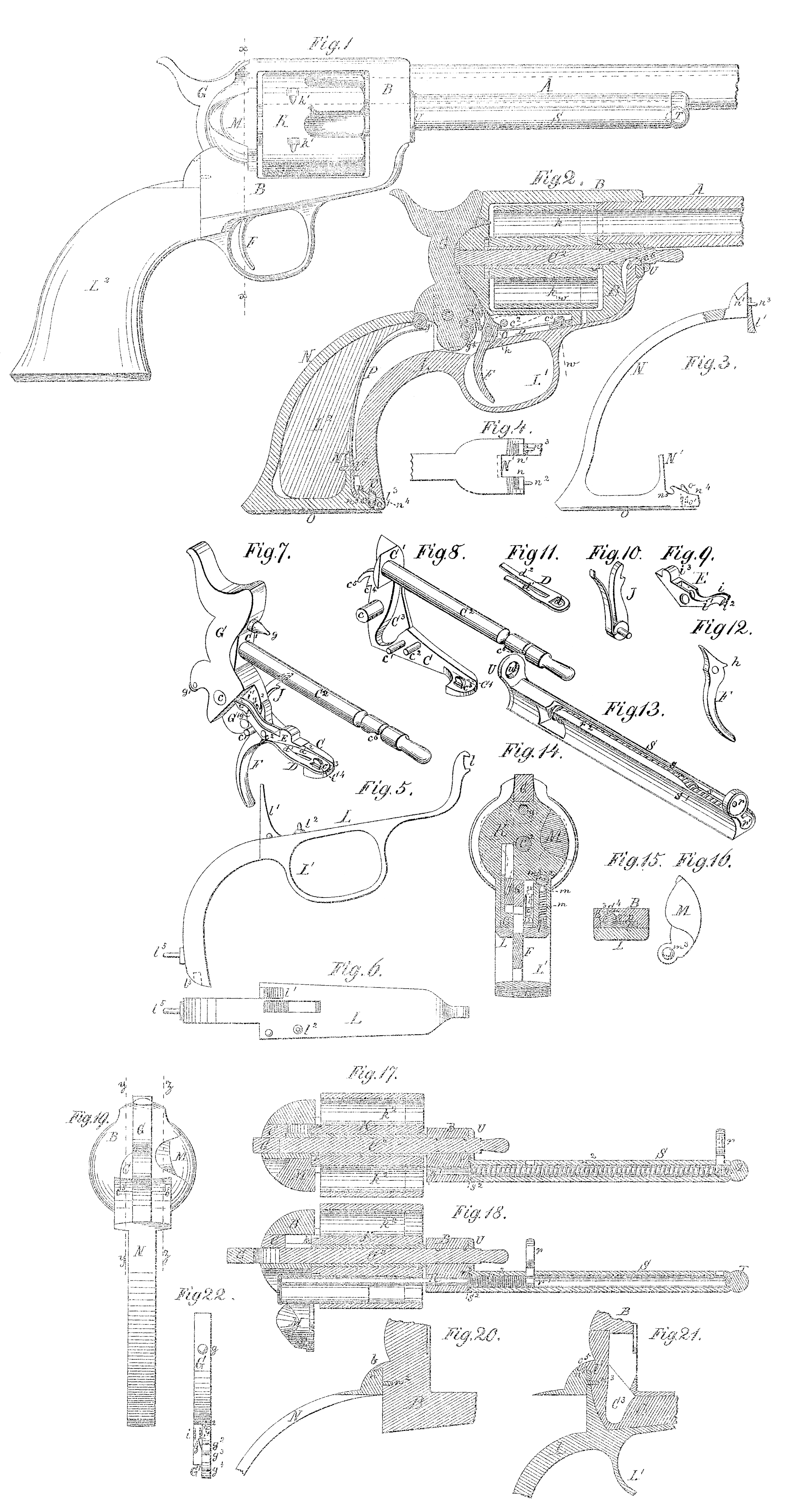

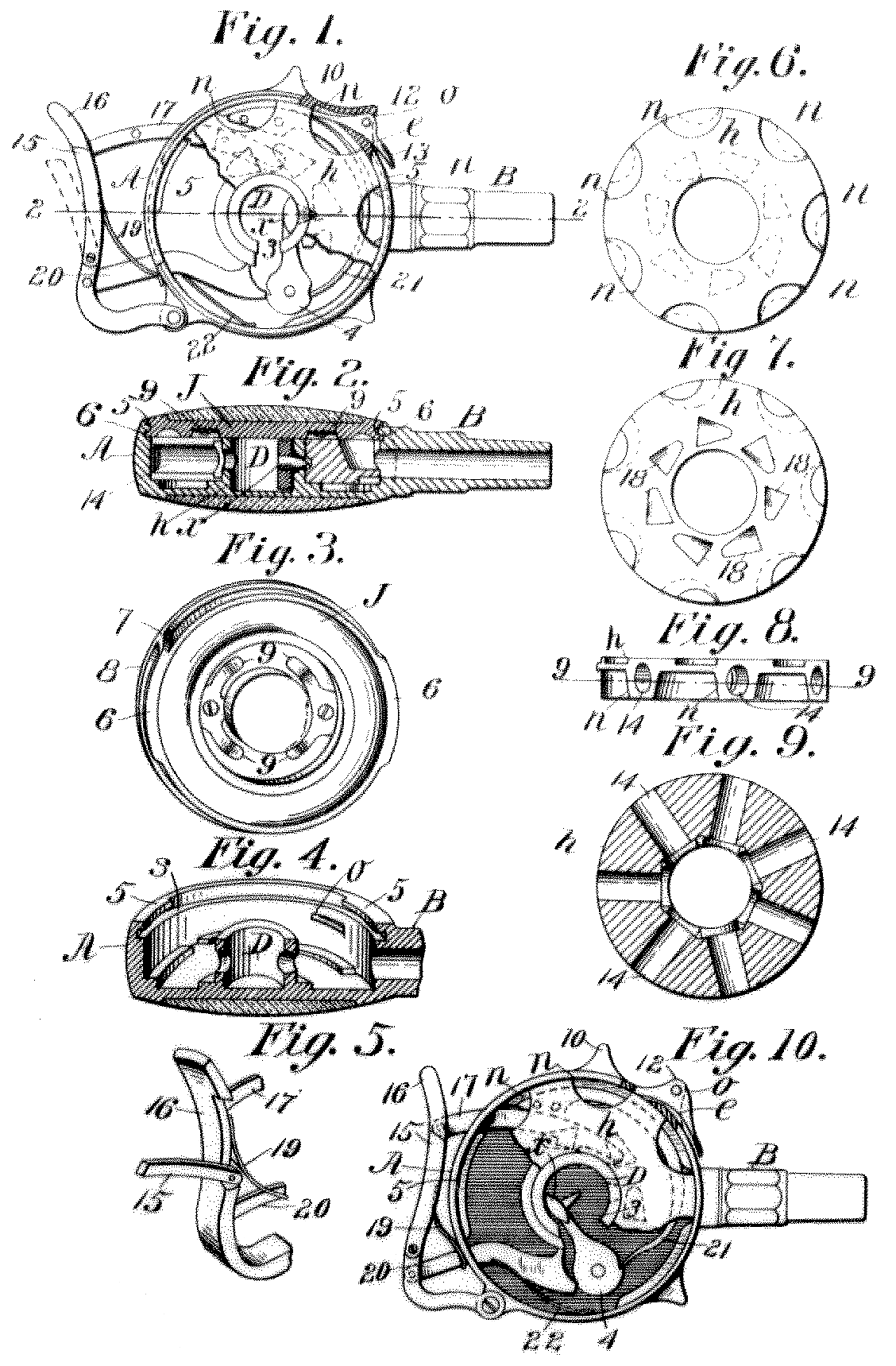

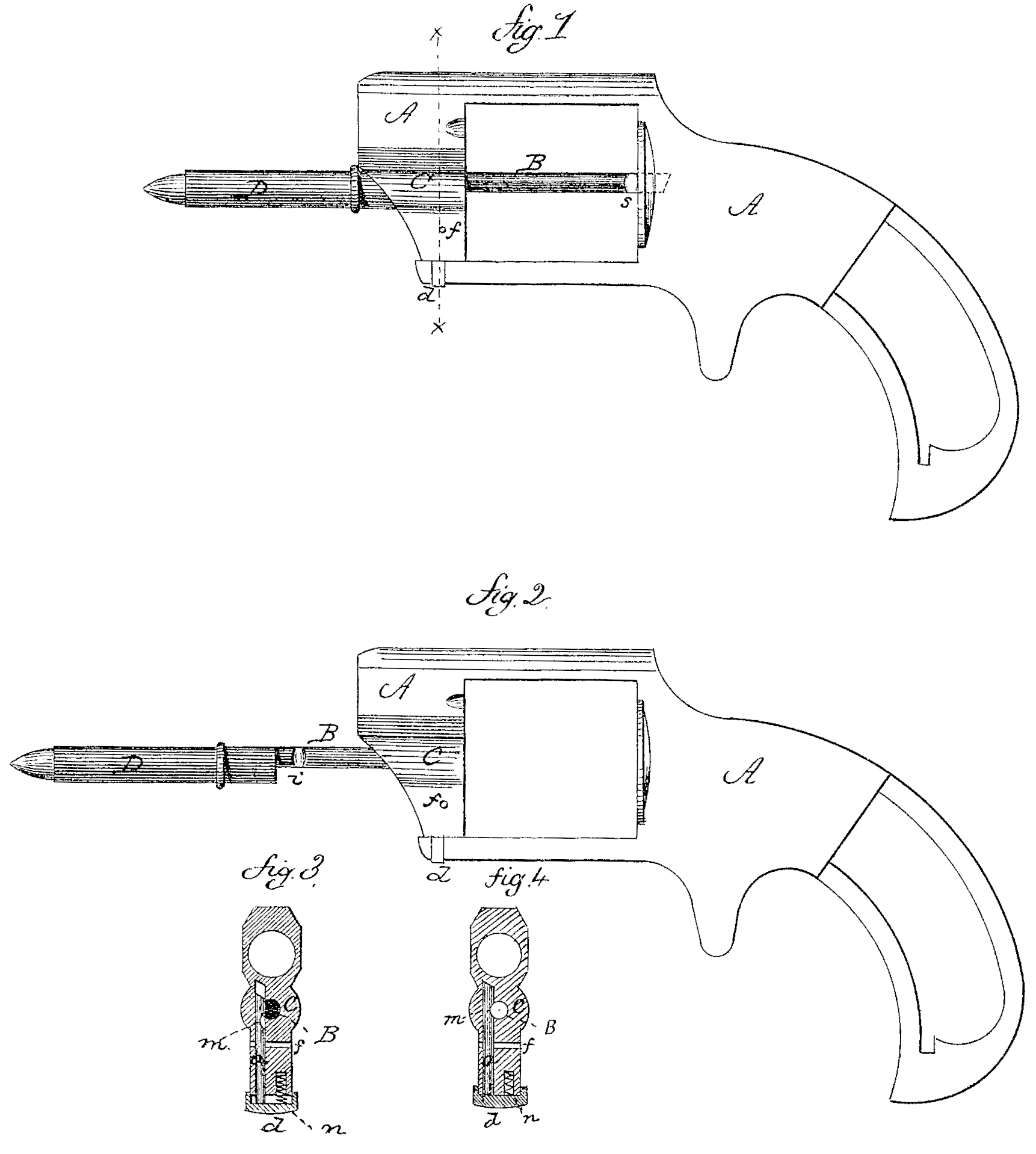

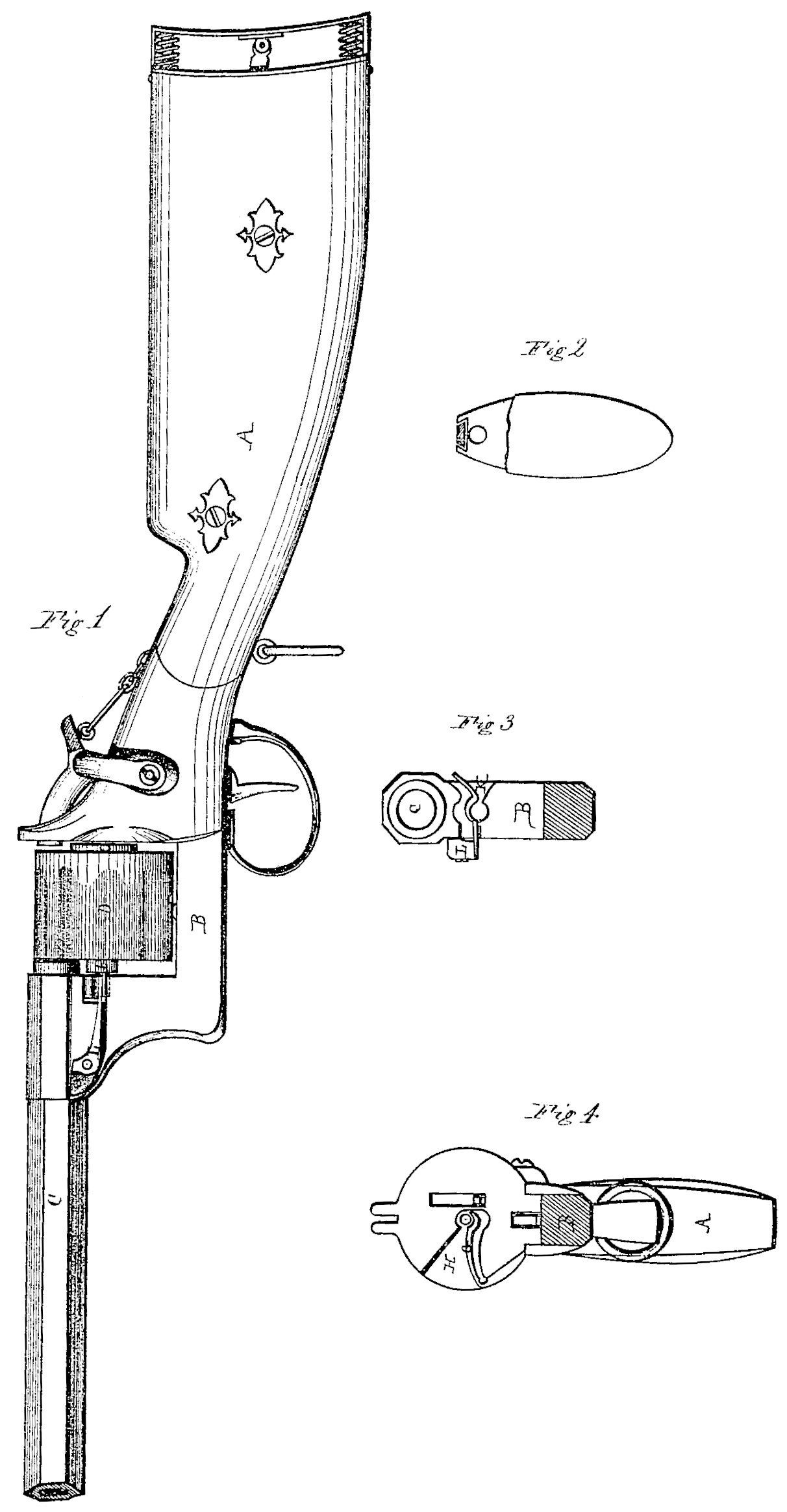

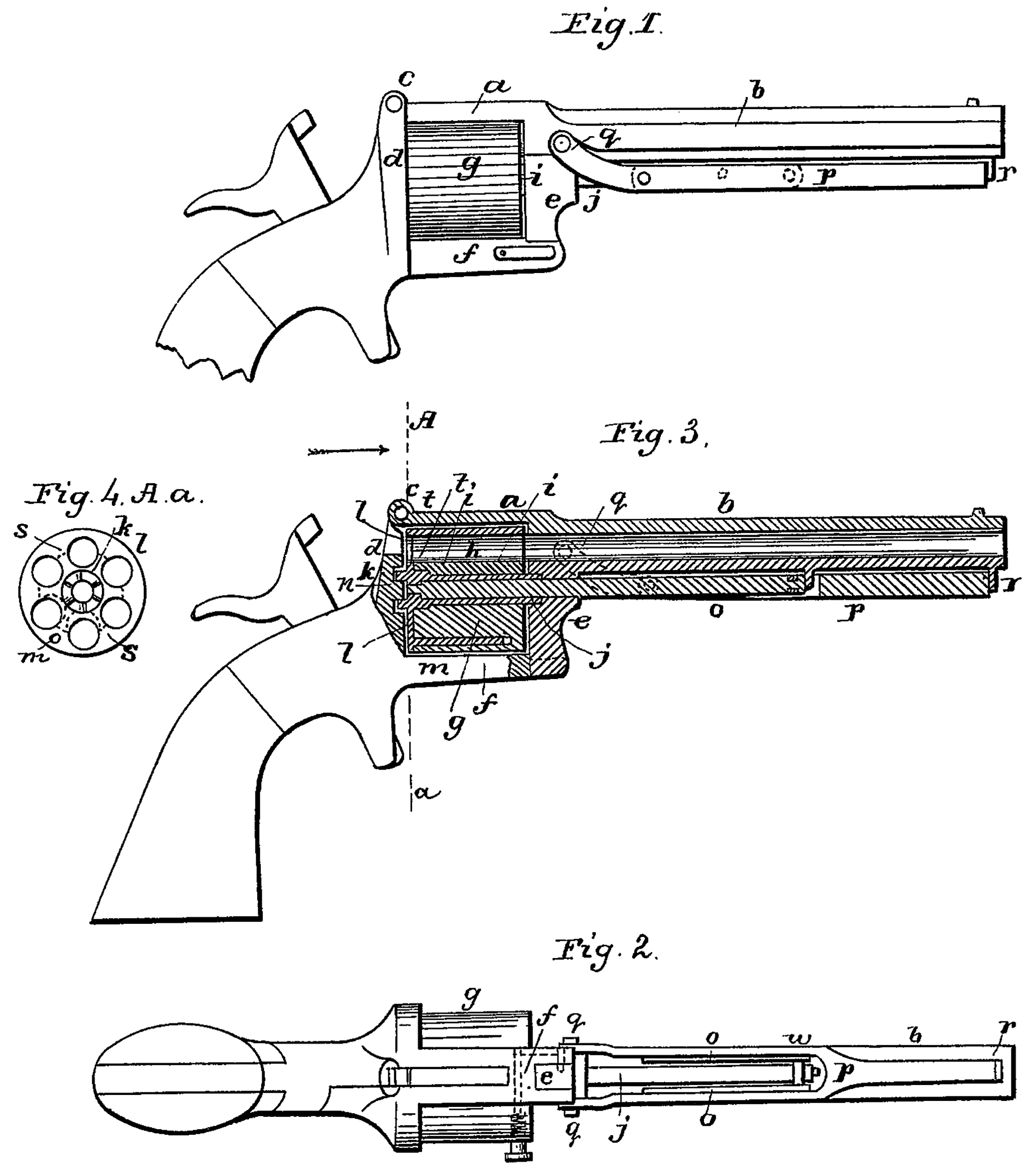

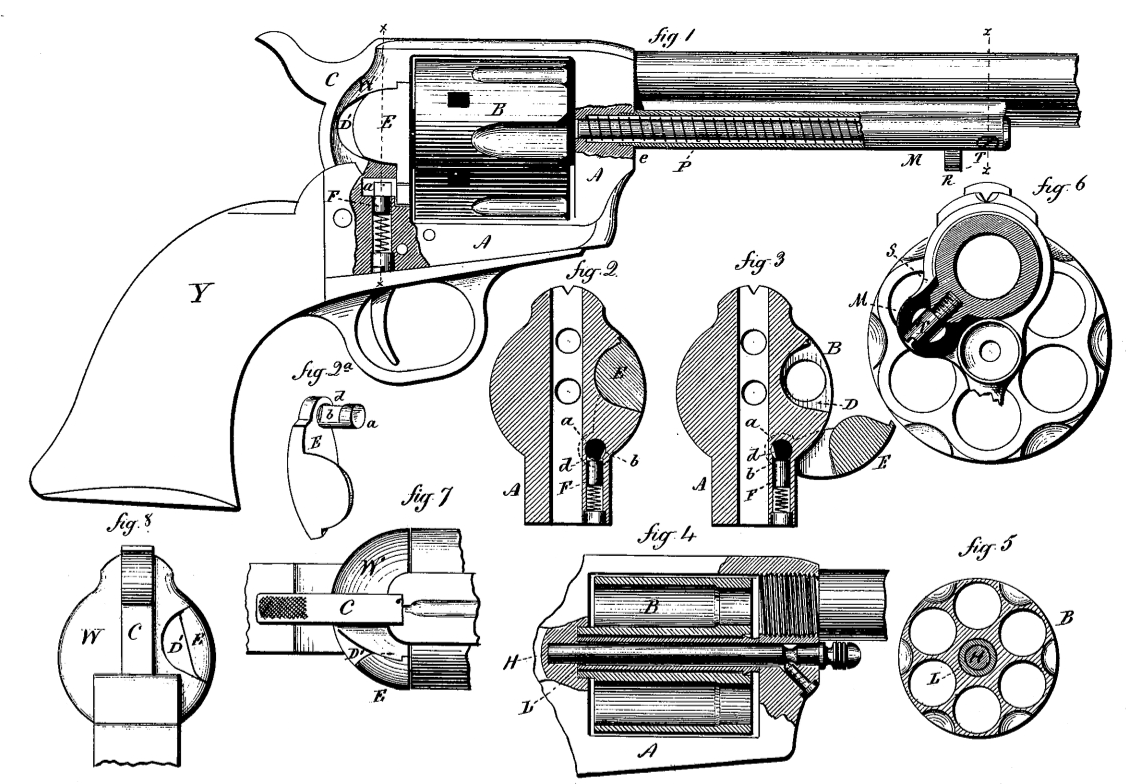

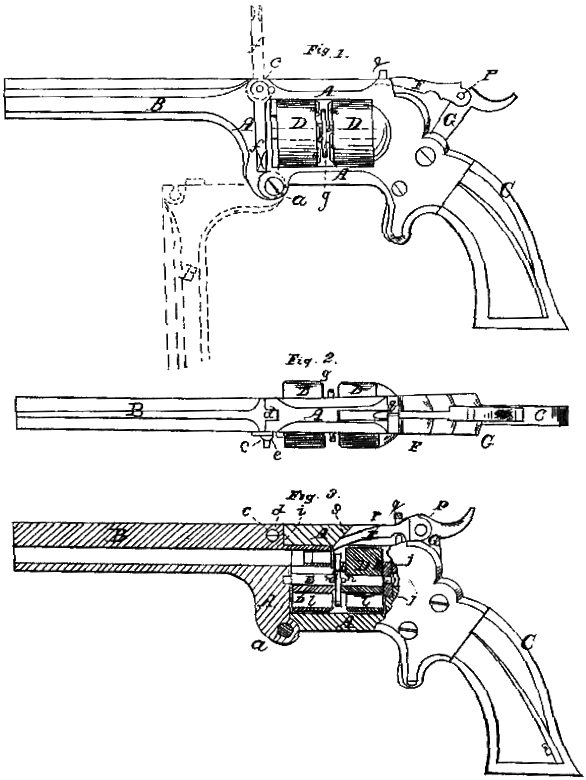

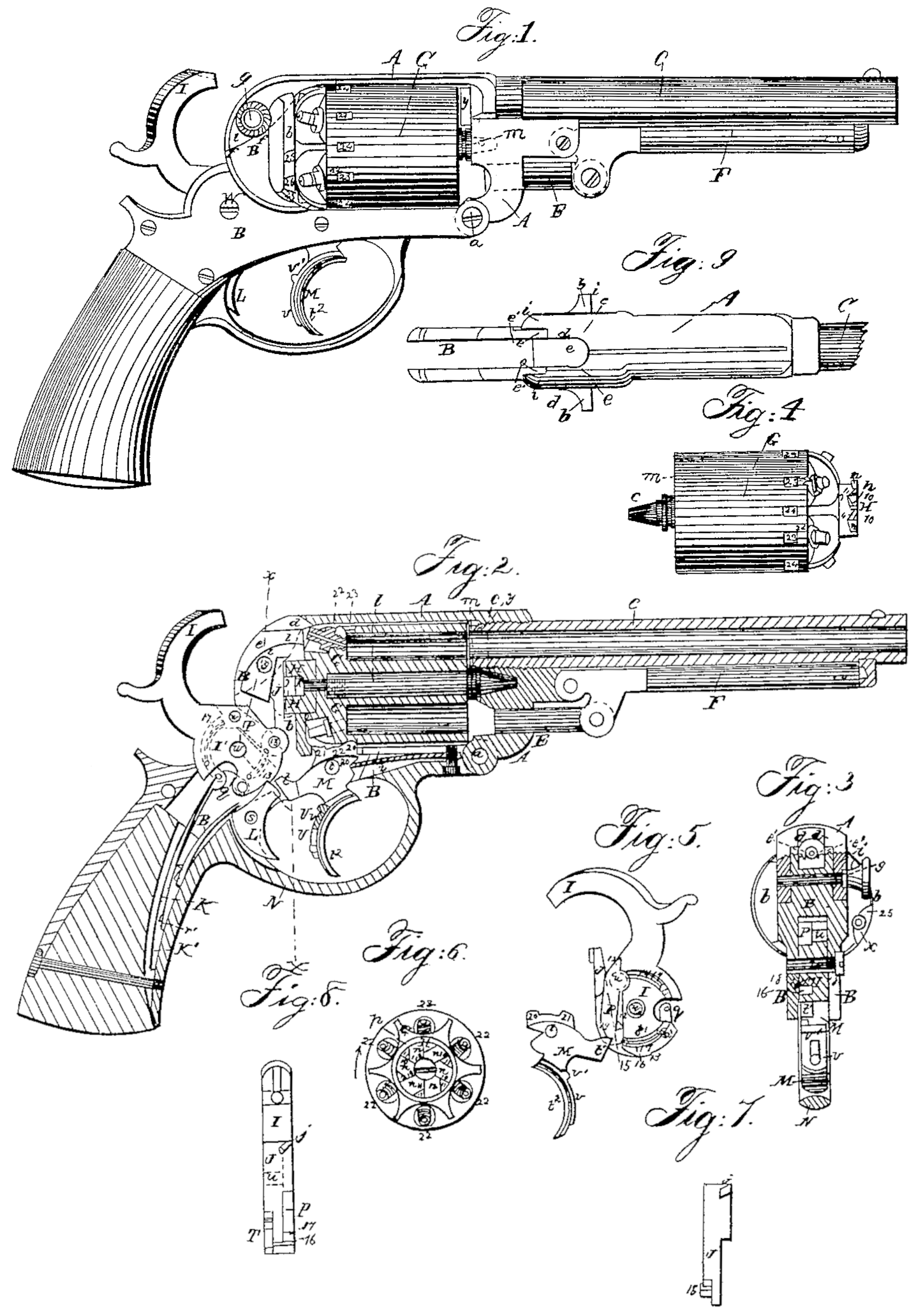

Figure 1 is a side elevation of a fire-arm or revolver with my invention applied to it. Fig. 2 is a vertical longitudinal central section of the same. Fig. 3 is a detailed view of the back or butt strap of the said fire-arm. Fig. 4 is a top view of the extreme upper end of the said strap. Fig. 5 is a side view of the guard-plate in detail. Fig. 6 is a top view of the guard-plate. Fig. 7 is a perspective view of the lock-plate and the parts supported thereby. Fig. 8 is a perspective view of the lock-plate and rod of the revolving chambered cylinder combined, in detail. Fig. 9 is a perspective view of the cylinder check or pawl. Fig. 10 is a perspective view of the spring pawl, whereby the said cylinder is propelled or revolved. Fig. 11 is a perspective view of the combined split check and trigger spring. Fig. 12 is a perspective view of the trigger. Fig. 13 is a perspective view of the cartridge-case extractor or expeller. Fig.14 is a vertical cross-section in the line x x of Fig. I looking toward the muzzle. Fig. 15 is a sectional view of the locking device of the front part of the lock-plate in the line w w of Fig. 2. Fig. 16 is a full view of the breech-gate leading to the chambers of the revolving cylinder. Fig. i7 is a central horizontal section through the cartridge-case expeller and the revolving cylinder, in a position for either loading the arm or expelling the empty cartridge-case. Fig. 18 is the same section as Fig. 17, showing the operation of expelling the cartridge-case. Fig. 29 is a back view of the revolving fire-arm. Fig. 20 is a detail section of the same in the line y y of Fig. 19. Fig.2i is a detailed section of the fire-arm in the line z z of Fig. 39; and Fig. 22 is a detailed view of the hammer and cylinder check.

The nature of my invention consists in the construction, combination, and arrangement of parts, hereafter described and specifically claimed, whereby a fire-arm is produced in which the movable parts are provided with the bearings of the lock mechanism, and wherein the said movable parts are so interlocked with each other and with the cylinder-frame that they may be taken apart in succession, either singly or in groups, or both by detaching the parts which form the last connection in putting the fire-art together.

The object of my invention is to enable the operator to take the fire-arm to pieces, at to put it together by hand without the avid of instruments. Another object of my invention is to avoid weakening the cylinder-frame by drilling holes into it for the reception of pins and screws. A still further object of my invention is to five the fire-arm a neat appearance by means of smooth and will-polished surfaces, and by avoiding unsightly appearances of the same by dispensing with the use of exposed pins or screws in uniting the parts together.

In the drawings, A represents the barrel of a gun or pistol which is fastened to a cylinder-frame, B, which in the main is of ordinary construction. The lock mechanism of the said fire-arm is attached to a lock-plate, C, which is provided with bearings c for the hammer c^1 for the trigger, and c^2 for the cylinder-check, and which is also, by means of lap, C^1, connected with the cylinder-rod C^2. The form part of the said lock-plate is provided with an eccentric or a cam-button, c^3, by means of which the combined trigger and check spring D is fastened thereto.

The spring d, as seen in Fig. 11, has an opening, d, of the same shape as the button c^3, but arranged in a different position, so that it may be passed over the said button with the spring D held a right angles with the lock-plate, and by turning the said spring into the right position it becomes fastened on the neck of said button. The button c^3 is provided with an inclined surface, C^4, which forms, with the corresponding surface, B^3, in the cylinder-frame, a dovetail connection, the purpose of which is to prevent downward movement of the lock-plate. The spring D has has two branches, d^1 d^2, the former for operating the cylinder-check E, and the latter for operating the trigger F. The upper part of the lock-plate C is provided at the back with a step, c^4 and a downwardly-bent lip, c^5, the use of which will be hereafter fully described. The cylinder-rod C^2 is near its forward end provided with an inner step, c^6, the purpose of which will be hereafter explained. Upon the bearing c the hammer G is fitted, which is provided with a firing-pin, g, a friction-roller, g^1, for the mainspring, and a first, second, and third rest, g^2 g^3 g^4, respectively. Upon the bearing c^1 tie trigger F is fitted, and by means of the lip h operated by the spring-arm d^2. Upon the bearing c^2 the cylinder-check E is fitted, the back part of which is vertically divided into two thin elastic arms, i i^1, one of which, i^1, bears on the reduced lower part G^1 of the hammer G. The said reduced part G^1 is provided with a lifting-ratchet step, g^5, by means of which the arm i^1 is lifted, when the hammer is cocked. When the hammer descends the ratchet g^5 slides past the rounded upper corner i^2 of the arm i^1, and, pushing the arm out of the ay, resumes its normal position below the said arm. The lower part of the hammer G is also provided with a spring-pawl, J of ordinary construction, which is operated in a depression, C^3, in the locking-plate, and revolves the cylinder K by means of a ratchet-head, k, constructed as unusual in that class of fire-arms. The chambered cylinder K is provided with a notch, k^1, near each chamber k^2, into which the head i^3 of the spring-cheek E fits, and thereby holds the cylinder in position during the firing of the arm. The lock-plate C is so inserted into the lower part of the cylinder-frame that its lower side is flush with said part. A guard-strap, K, is fitted on the lower side of the cylinder-frame and fastened to the front part of it by beans of a hook, l, which enters the metal of said frame in such manner as to abut against the step c^5 of the cylinder-rod C^2, thereby preventing it from moving longitudinally. The guard-strap L is provided with a projection, l^1, which, in its normal position, is behind the lock-plate Cm and fits into the step c^4. A teat-pin, l^2, on the upper surface of the guard-strap L is provided with a projection, l^1, which in its normal position, is behind the lock-plate C, and fits into the spec c^4. A teat-pin, l^2, on the upper surface of the guard-strap, serves as a stead-pin by entering the metal of the cylinder-frame. Above the pin l^2 a hole is drilled into the cylinder-frame, and into it a spiral spring, m, with a piston, m^1, attached to it, is inserted, which bears on the corner m^2, formed by two flat surfaces on the corner m^2, formed by two flat surfaces on the pivot, m^3, of the breech-gate M, and thereby keeps the said breech-gate either opened or closed, as shown in Fig. 14. Below, and on the guard-strap, the trigger-guard L^1 is formed. The rear end of the guard-strap is inserted into the wooden or ivory handle L^2, and ends at the lower forward corner of the same, where it is provided with a slope, l^3, a vertical socket, l^4, and a horizontal pin, l^5. A back-strap, N, is inserted into the back and bottom of the handle L^2, and is interlocked with the cylinder-frame by means of a lip, b, at the rear upper corner of the cylinder-frame B, and a notch, n, at the forward end of the said back-strap. Another notch, n^1, opposite the notch n, interlocks with the lip c^5 on the lock-plate C. Below the said notches, which are separated by a vertical slot N^1, for the reception of the hammer G, the back-strap N is provided with two horizontal steady-pins, n^2 n^3. The pin n^2 enters the back of the breech of the cylinder-frame B, as seen in Fig. 20, and the pin n^3 passes through the projection l^1 of the guard-strap L into the lock-plate C, as seen in Fig. 21.

The lower part of the back-strap N is provided with a spring, O, and a pin, o, which latter passes through the metal of the back-strap and into the socket l^4 of the guard-strap. The pin o is near the spring O reduced in thickness, as at o^1, and the hole in guard-strap in which it operates is made accordingly, as shown in Fig. 2. so that the said pin cannot be entirely pulled out of the back-strap. The lower forward end of the back-strap is provided with a slope, n’, which matches the slope l^3 of the guard-strap. An upright lug, N^1, on the back-strap is entered by the pin l^5, and prevents separation of the straps L and N in a vertical direction; and it also serves, in connection with the pin l^5 and a notch, n^5, at its foot, as means for fastening the mainspring P, which is thereby clamped between the strap L and the lug N’, and also prevented from slipping vertically. The spring P is provided with a hook, p, which fits into the notch n^5. The expeller of the cartridge-cases consists of a rod, R, with a thumb-plate, r, and a, head, r^1, loosely fitted into a case, S, and provided with a spiral spring, r^2. The case S is open at both ends, and is provided with a slot, s, in which the neck of the thumb-plate r moves, and the said slot may extend from end to end of the case, or may be stopped hear one of the said ends, so that the rod R may be removed with its thumb-plate r from the open end. The front end of the case S fits upon a projection, t, on a lug, T, upon the barrel A of the fire-arm, and the back end of the said case as a flange, U, with a hole, u, through which the cylinder-rod C^2 passes, while the flange itself fits on the front end of the cylinder-frame B, and by this means is prevented from longitudinal movement. I prefer to provide the case S with a curved basis, s^1, which fits upon the barrel A, whereby the said case is prevented from turning. The rear end r^3 of the spring r is enlarged in diameter, and the rear end of the case S is provided with a countersunk enlargement, s^2, for its reception, so that, the spring r^2º bears upon the front face of the cylinder-frame and upon the rear shoulder of the head r^1 of the rod R. The rear end of the case S may be closed around the rod R, and thus provide a bearing for the rear end of the spring r^2. The rod R is as long as the case S, and does not enter the cylinder-frame in its normal position, so as to hinder the separation of the case from its fastenings. The rod R, when operated, is guided through a hole b’, in the cylinder-frame.

Operation: The loading and firing of the described fire-arm are effected in the same manner as that of any ordinary fire-arm of the same class, and therefore need no description. The separation of the lower parts of the said fire-arm begins as the lower forward end of the handle. The spring O is at its forward end bent down until the pin o has left the socket l^4, whereupon the lower end of the back-strap N is swung back and off from the pin l^5, the pins n^3 n^3 leave their sockets in the cylinder-frame B, and the lock-plate C and the upper end of the back-strap are removed downward from the locking-lips band c^5. Thus the back-strap N, the handle L^2, and the mainspring P become detached from the arm. The mainspring P is now swung out of its lower notch n^5, and the handle L^2 removed from the back-strap b swinging its upper end down and then pulling it off sidewise, The guard-strap L is now swung forward after the hammer G has been raised into the second rest, and the trigger thereby moved forward to permit the guard-strap to pass over it, for the purpose of being unhooked at its front end l. The hammer remaining at half-cock, the cylinder-rod C^2 is pushed out of its bearing, whereby the lock-plate, with the lock mechanism, is removed from the cylinder-frame. By having the hammer half-cocked, the cylinder-check E is so much lowered as to slide over the cylinder and permit the withdrawing of the lock-plate. The cylinder-check E is now removed from its bearing c^2, the trigger F is then removed form its bearing c^1, the spring D is turned at a right angle to the lock-plate and passes over the button c^3, the hammer G is then removed from its bearing c, and spring-pawl J separated from it. The case S is swung from the cylinder-frame and removed from the barrel A, the rod R is removed by sliding it out in a forward direction, and the spring r^2 is removed from the rear.

The described operation is reversed when the fire-arm is to be again put together. The principal movable parts of the lock mechanism shown are similar to those used in Colt’s revolvers, and I have simply made use of them for the purpose of illustrating my invention, and of showing the improved mode of fastening them without the use of removable screws and pins. It is easily seen that my improved system of fastening and interlocking the described parts can be adapted to all kinds of fire-arms with a very slight and unimportant alteration of the shape, whereby these parts are made to conform to the shape or outlines of such fire-arms. For instance, the stock of a revolver, gun, or carbine would require a longer back-strap and a straighter guard-strap without necessitating a change in the construction of the described final interlocking device.

There are many modifications of the means whereby the parts described may be fastened and interlocked without departing from the principle of my invention, and I therefor do not confine my claims to the precise construction of the said parts.

The advantages of the described invention are, a strong compact fire-arm of elegant appearance, which is not disfigured by screw or pin heads or ends, and which can be taken apart very rapidly by hand; and consists of less parts than any similar fire-arm in which the parts are secured by screws and pins, and of which no part can be lost by accident, as is so often the case with screws and pins in ordinary fire-arms.

Having described my invention, what I claim as new, and desire to secure by Letters Patten, is—

1. A continuous connection of parts in pistols extending throughout the arm, finally locked by a single device substantially as described, whereby all the parts are secured in their positions, and by the unlocking of the said locking device all the pieces become detachable successively or in groups, substantially as set forth.

2. A locking device, substantially as described, for a revolving fire-arm, by the unlocking of which all the parts previously connected may be disconnected, substantially as set forth.

3. In a revolver, a removable or detachable lock-plate carrying the lock mechanism and the revolving mechanism, substantially as described.

4. The lock-plate C and the cylinder-rod C^2, united together and supporting one another; substantially as set forth.

5. A detachable lock-plate adapted to be inserted into its seat in the breech-frame, and to be held therein by the removable parts contiguous to it, substantially as described.

6. The back-strap N, having its upper end fastened to the cylinder-frame B, the lock-plate Cm and the guard-strap L, having its lower end interlocked with the lower end of the back-strap B, substantially as described.

7. The combination of the lock-plate C, carrying the cylinder-rod C^2, the latter having a notch, c^6, and the guard-strap L, having a hook, l, and a projection, l^1, substantially as described.

8. The final locking device, consisting of the spring Om provided with the pin o attached to the back-strap, and the guard-strap L provided with the socket l^4, substantially as set forth.

9. The combination of the back-strap N, having lug N^1, the guard-strap L, having the pin l^5, and a latch-fastening, substantially as described.

10. The combination of the back-strap N, having the lug N^1, and the notch n^5, with the pin l^5 of guard-strap L, and the spring P, substantially as set forth.

11. The combination of the cylinder-rod C^2 and the extractor0case S, having a flange, U, substantially as set forth.

12. The combination of the barrel A, provided with a lug, T, having a projection, t, and the extractor-case S, for holding said case in position, substantially as set forth.

13. The extractor or ejector case S, provided with an enlargement, r^3, at the rear end of its bore, as and for the purpose described.

14. The means herein described for securing the spring D to the lock-plate C, consisting of the button c^3, so shaped that when the corresponding shape opening in the spring is placed over it, and a partial turn given to said spring, the latter will be fastened in place as set forth and described.

15. The combination of the main spring P, having a hook, p, and the back-strap N, having a notch, n^5, substantially as set forth.

16. The combination of the guard-strap L, the teat-pin l^2, the cylinder-frame B, the spring m, and the piston m^1, substantially as set forth.

17. The combination of the frame B and the guard-strap L, having the hook l, and a fastening device on the rear stock, whereby the two parts are connected together so as to be separated by a downward-swinging movement of the guard-strap, substantially as described.

18. The combination of the cylinder-frame B, the guard-strap L, having the hook l, and the cylinder-rod C^2, having he notch c^6, substantially as set forth.

19. The combination of the lock-plate C, having a button with an inclined surface, C^4, and the cylinder-frame B, having an inclined surface, B^3, substantially as set forth.

20. The combination of the guard-strap L, provided with the lug l^1, the lock-plate C, and the back-strap B, with the pin n^3, substantially as set forth.

Witness my hand in the mater of my application for a patent for an improved breech-loading revolver, this 11th day of July, 1876.

FRANK W. FREUND.

Witnesses:

J. W. Bruner,

J. R. Whitehead